3mm PVC Foam Sheet - Plastic Sheets / Lamination PVC Foam Board

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

PVC Foam Sheet, a kind of high-tech product, is one product of Kingstar Plastic Sheet searis. Through special machinery and technology processing, the main material PVC resin can be foamed and extruded into a special sheet with many advantages, such as shinny or matt surface, waterproof, flame-resistant, UV stable, sound and heat insulation, anti-chemical corrosion, etc.

Feature

1. Moistureproof, waterproof, shock absorption and mothproof

2. Fire retardant and self-extinguishing, Heat preservation

3. Sound insulated

4. Insulation

5. Perfect chemical corrosion resistance, good resistance to UV & weathering Non-toxic

6. Non-deformation

7. Non-formaldehyde emission

8. Stable color retention

9. surface is very smooth, rigid and not easy to scratch. Uniform fine & close cell structure

10. same processing as timber, but processing performance is much better than wood

11. Light weight, easy and convenient to storage, transportation and use

12. It is machinable could be drilled, sawed, nailed, turned, glued, bended, printed, oiled, etc

13. Smooth surface and suitable for silkscreen printing, laser engraving (must clean the surface before printin

Application

1. Advertisement exhibition & display,digital printing,silk screen printing,engraving materials,sign board,etc.

2. Fumitureoffice furniture, cabinet, bath cabinet,etc.

3. Finishing materialdecorative sheets, storage racks,. room segments, etc.

4. Industrial application:thermoforming products, refirgeratory warehouse project, environmental protection.

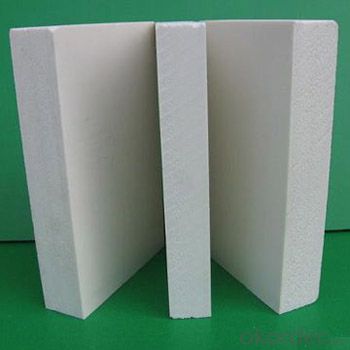

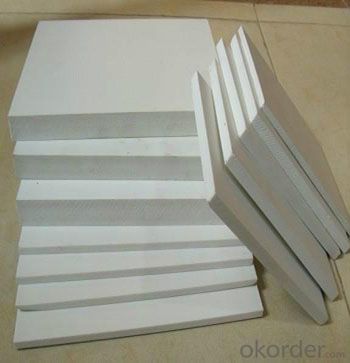

photos:

- Q: I want to know if it is durable, and transmit light. I want to use it for my green house, but, it has to be a thick plastic but not light obscuring.

- While 6 mil is very thick for plastic film, it can also be grainy and tear easily. Here are some examples for plastic film: Grocery bag 1mil Trash bag 1.5 to 2 mil Medical waste red bag either 2 - 2 mil or 1 - 4 mil Plastic sheeting comes in many grades and thicknesses, for best overall performance and durability I prefer 4 mil, clear Also, you might want to consider a ridged fiberglass sheet, strong enough to support heavy weights, but light and easy to handle. Sheets come in 2 ft x 6 ft or 2 ft x 8 ft, these come in clear or opaque depending on what you intend to grow the opaque might be preferable.

- Q: You know like 'pexiglas' or what ever. I need Something simular to that. Maybe .5 in or around there for the thickness. What could i Use?

- How large a piece do you need? Could you take a piece of canvas and glue plastic on one or both sides?? Also, you can buy plastic sheets for a bed (to prevent soiling the mattress)--glue some of those together.?? Or glue some tarps together?? Maybe plastic doesn't glue??

- Q: What are the different ways to join plastic sheets together?

- There are several different ways to join plastic sheets together, including adhesive bonding, thermal welding, mechanical fastening, solvent bonding, and ultrasonic welding.

- Q: POM what's the plastic board for?

- For instance:1, POM has a high hardness and steel;2 and POM have good anti creep and stress relaxation ability;3, POM has excellent wear resistance, self lubrication and fatigue;4 and POM have good dimensional stability, low water absorption and little influence on mechanical properties;The dielectric constant and dielectric loss tangent of 5 and POM vary little and have good dielectric properties.

- Q: I was wondering if there was any type of Vinyl or Plastic sheeting that you can adhere together by Melting it? to make a box or something?

- I believe you would have to do a cold-weld. Applying heat to vinyl or plastic is dangerous because of the fumes/fire. For a box, think about plexiglass. Plexiglass is very durable but scratches easily. The thickness of the plexiglass is; 1/8, 3/16 and 1/4 inches. The 1/4 thk. requires a fine-tooth blade to cut. The other 2 can be cut with a box-knife by passing the blade over about 6 times and then using a support edge can be snapped off. You can assemble using corner angles and small self-threading screws but pre-drill first.

- Q: I want to start vacuum forming, is there anyway for me to buy vacuum forming plastic localy in grand junction CO.?And is there anyplace here where they might do it for me?I can't buy online so don't post websitesAny info helps thnx.

- Try SSD PLASTICS, INC. They should sell most anything you would need. They also do fabrications and should be able to create any forms you need for your vacuum forming business.

- Q: Can plastic sheets be used for point-of-purchase displays?

- Yes, plastic sheets can be used for point-of-purchase displays. They are lightweight, versatile, and can be easily molded or cut into various shapes and sizes. Additionally, plastic sheets can be transparent or colored, allowing for attractive and eye-catching displays to showcase products in retail settings.

- Q: Do you actually know anyone who was scared into stockpiling plastic sheeting and duct tape?

- No but duct tape is great!

- Q: I'm tired of pulling grass out of my flower bed, I have put two layers of black plastic down and mulch and I have sprayed it with a safe against shrub grass killer. Please help!

- Maybe your mulch contains weed seeds? Maybe your mower has been shooting them into the garden? You can try using the pellets that you sprinkle into the beds like preen that also has flower fertilizer and weed controller.

- Q: Can I use wallpaper paste to stick gravel to plastic sheeting?I want to make, as cheaply as possible, a Sempervivum roof for a bee house in my garden and thought I could us a plastic sheet, gravel stuck on that, then earth and the plants.What's the easiest and less smelliest (bees don't like smells) glue I can use? Will wallpaper paste do?Thanks for reading.

- Wallpaper paste will not work in this application. It will turn to mush again as soon as moisture gets to it. Most adhesives that apply in liquid form will not work well, and almost all will have smell that remains for some time One adhesive that would work well both on plastic sheeting, have virtually no smell, and will remain solid under dirt is hot glue, but application is time-consuming, and you will have to be careful with the application temperature, as it has to stick onto the plastic, but not melt through it. A heavy-grade plastic sheet will be needed/ You have some choice in the melt points of the glue stick and can ask at the store about the lowest melt sticks they have. . The easiest solution to this might be a small craft-store glue gun and buy the sticks from them (or a dollar store) as they only use glue sticks that have a low melt point Before beginning your main work, practice applying the glue on a spare part of the sheeting and see how quickly you can work with it,

Send your message to us

3mm PVC Foam Sheet - Plastic Sheets / Lamination PVC Foam Board

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords