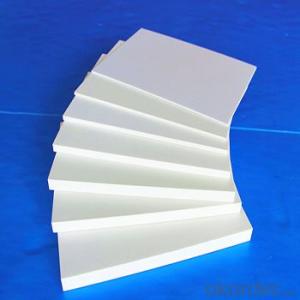

3mm hard pvc forex board /PVC extrusion profile hard plastic board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

specifications

(1-25)*1220*2440mm

(1-25)*1000*3000mm

(1-25)*2000*4000mm

Other size can be customized as your request.

color

Blue/black/grey/white/yellow/red/green -All of the colors are available

Feature

1. high chemical stability,fine anti-fire,super-transparent.

2. highly UV.stabilized,good mechanical properties,high hardness and strength

3.the sheet aslo has well aging resistance,good self-extinguishing property and reliable insulativity,

4.Moreover the sheet is waterproof and has very good smooth surface,and is non deformable

5. important item: anti-static,anti-UV.

1.1.High shore hardness:80-90;

1.2.Water absorption < 0.5%;

1.3.High mechanical strength, its hardness & rigidity is better than polyethylene;

1.4.Well wear-resisting, higher than culcanized rubber;

1.5.It owns good electrical insulating property and ageing resistance;

1.6.Good flame retardancy;

1.7.Noise elimination performance;

1.8.High impact strength

1.9. Good acid and alkali resistance

Properties | Item | Reference specification | |

physical properties

| Density | 1.3–1.45 g/cm³ | |

Water-absorption (24h,3.18mm thickness) | 0.07-6.4% | ||

Chemical stability | excellent | ||

mechanical property

| Tensile strength | 25.7-64.5MPa | |

Bending strength | 71.6-114.7MPa | ||

Impact strength | 2.18-109kJ/m | ||

thermal property

| Coefficient of thermal expansion (linear) [mm/(mm °C)] | 5-18.5×0.00001(1/℃) | |

Fire resistance | self-extinguishing | ||

Softening point | 54-74℃ | ||

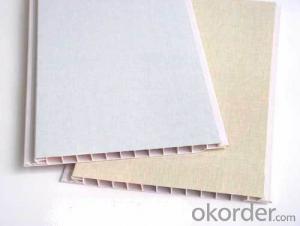

Application

1.Advertisement: exhibition & display,digital printing,silk screen printing,engraving materials,sign board, etc.

2.Furnitureoffice furniture,cabinet,bath cabinet,etc.

3.Finishing Materialdecorative sheets,storage racks,room segments,etc.

4.Industrial Application:thermoforming products,refrigeratory warehouse project,environmental protection.

5. Application:chemical industry,oil industry,galvanization,water purification equipments.

6. Application: environment protection equipments,medicall ppliance and so on

- Q: Can plastic sheets be used for lampshade covers?

- Yes, plastic sheets can be used for lampshade covers. They are a popular choice as they are durable, easy to clean, and come in a variety of colors and patterns.

- Q: what are the plastic sheets called that soldiers sleep unter when sleeping outdoors?

- Plastic sheets

- Q: Can plastic sheets be used for greenhouse insulation?

- Yes, plastic sheets can be used for greenhouse insulation. They are commonly used as a cost-effective option to trap heat and create a controlled environment inside the greenhouse. Plastic sheets can provide insulation by reducing heat loss and preventing cold air from entering the greenhouse, helping to maintain a stable and optimal temperature for plant growth.

- Q: Are plastic sheets resistant to cracking from impact?

- Yes, plastic sheets are generally resistant to cracking from impact.

- Q: What is the PP board, PE board?

- The PP board is polypropylene plastic plate, PE polyethylene plastic plate.

- Q: I want to make my own slip and slide tomorrow and i am going to use some plastic drop sheets.But i need to find a shop to get it for tomorrow. Anyone know of large retail shops that sell them? Thanks

- difficult problem. query at a search engine. that will can assist!

- Q: Can plastic sheets be used for insulation?

- Yes, plastic sheets can be used for insulation. They provide a barrier that helps to reduce heat loss or gain, depending on the desired insulation effect. Plastic sheets such as polyethylene or polystyrene are commonly used in building structures to improve energy efficiency and thermal comfort.

- Q: I want to use plastic pallet (made from polypropylene material) to store drum's (bout 200 kg each), it was so slippy. So i want to put a rubber grip on it.. i wonder how to stick a rubber grip at plastic pallet? pls help me.. thanks all.

- you could use a glue called gorilla glue. It is the strongest type of glue i know... The only thing is that you can not get it on your hands because if you get it on your hands and you touch something, you are going to be stuck and will have to wait for the glue to wear off and because the glue is waterproof, you should watch out. If you are interested, check this site out. You can Gorilla glue at Wal-Mart(it most likely there)

- Q: Do plastic sheets have UV protection?

- Yes, plastic sheets can have UV protection. Many plastic sheets are made with additives that help block or absorb ultraviolet (UV) rays, providing protection against sun damage and fading.

- Q: Are plastic sheets resistant to cracking from heavy loads?

- Yes, plastic sheets are generally resistant to cracking from heavy loads. However, the level of resistance may vary depending on the type and quality of plastic used.

Send your message to us

3mm hard pvc forex board /PVC extrusion profile hard plastic board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords