3mm Corrugated Polypropylene Plastic Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

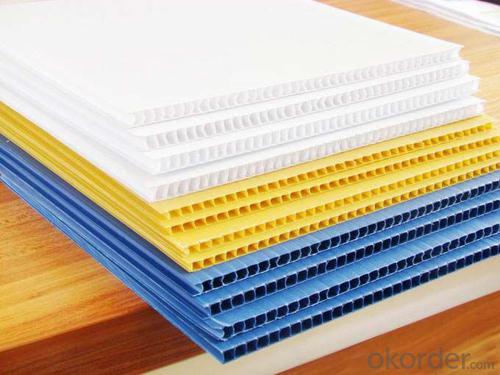

CMAX PP Plastic Hollow Sheet is an extruded twin wall plastic sheet consisting of two flat walls connected by vertical ribs. Eco-friendly PP Plastic Hollow Sheet is mainly manufactured from a high impact co-polymer polypropylene (PP) or polyethylene (PE) resin, which can be recycling, washable, durable and re-useable etc. CMAX Polypropylene PP Twin Wall Corrugated Plastic Hollow Sheets / Board / Signs has proved that it is suitable in the uses of packaging, advertising, construction, agriculture, industry and Pharmaceutical etc.

Specification:

1. Thickness: 2mm,3mm,4mm,5mm,6mm,7mm,8mm,10mm,12mm

2. Weight: From 250g/m2 to 3500g/m2

3. Standard Size: 2440mmx1220mm, 2000x1000mm, 1200x800mm, 1000x1000mm or as request

4. Grade:Corona Treated, Anti-Static, Conductive, UV Stabilized and Flame Retarded etc;

Feature:

CMAX Polypropylene PP Corrugated Plastic Hollow Sheet offers efficient solutions to a wide variety of applications. Compared to alternatives such as cardboard, metal or rigid plastic, Eco-friendly Twin Wall Corrugated Plastic Polypropylene PP Hollow Sheet offers the following unique advantages

1. Economical : both in use and purchase

2. Flexible : as a material and as application

3. Environmentally sound : recyclable

4. Water and moisture resistant

5. Approved for food packaging

6. Strong and durable

7. Lightweight

8. Good chemical resistance

9. Easy to print

Description | PP hollow sheet/PP corrugated sheet is a kind of environmental material, which is pollution-free and recyclable, made of polypropylene (PP) and polyethylene (PE) | |||||||||

Width | ≤2100mm | |||||||||

Length | As required. | |||||||||

Thickness | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 9mm | 10mm | 11mm | 12mm |

GSM | 250-500 | 300-600 | 600-900 | 800-1200 | 900-1600 | 1400-2000 | 1600-2000 | 1600-2200 | 2200-2400 | 2400-2600 |

Application | Packing | Transfer Box,mail box,display rack,partition,gift box,food packing,turnover box,dustbin,etc. | ||||||||

Advertising | Sign board,exhibition board,billboard,caution board,picture frame backing,digital printing and screen printing. | |||||||||

Decoration | Partitions,wall cladding,indoor and outdoor decoration,windows and false ceilings,floor cover,greenhouse roof. | |||||||||

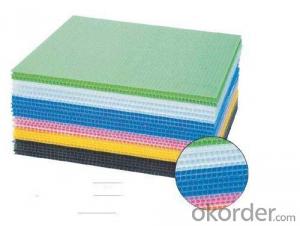

Stationery and art design | It has multi-color,suitable for art design & various pattern box or delicate gift pack. | |||||||||

Feature | Light weight,rigid,strong and long time durable. | Waterproof,moisture resistance,excellent weather ability. | ||||||||

Chemical resistance,anti-impact,fade resistance. | Environmental friendly,recyclable,washable,non-toxic. | |||||||||

Easy to fabricate,custom-made cut shape. | Excellent surface for paints and inks easily,anti-corrosion. | |||||||||

Grade | Common,Corona Treated,Anti-Static,Conductive,UV Stabilized,etc. | |||||||||

Color | Clear,Black,White,Blue,Red,Yellow,Green,Pink,Or as required. | |||||||||

Advantage | Capacity:600MT per month; Prompt delivery; Factory Direct Selling; ISO-9001 | |||||||||

FAQ:

1. Where is you factory located?

Our factory is located near Shanghai. Your order will be delivered to Shanghai port quickly.

2. What kinds of materials do you use?

Normally, we use both virgin and recycled materials for production

3. How can you guarantee the quality?

We have more than 20 employees who are engaged in quality inspection, we promise every sheet comes out of our factory is guaranteed.

- Q: What are the environmental impacts of plastic sheets?

- Plastic sheets have several environmental impacts. Firstly, their production contributes to the depletion of fossil fuels and the emission of greenhouse gases. Secondly, when plastic sheets are improperly disposed of, they can end up in landfills or oceans, taking hundreds of years to decompose and contributing to pollution. Additionally, plastic sheets can harm wildlife and marine ecosystems, as animals may mistake them for food or become entangled in them. Overall, the use and disposal of plastic sheets have negative consequences on the environment and highlight the importance of reducing plastic waste and finding sustainable alternatives.

- Q: in construction.

- Do you mean HDPE Sheet? HDPE stands for High Density Polyethylene. HDPE Sheet has very low friction properties which are some of the best within the engineering plastics range and HDPE Sheet helps produce low friction components. HDPE Sheet also has excellent abrasion resistance which helps provide components that are suitable for high abrasion applications. HDPE Sheet will absorb very low amounts of moisture which help creates components that are stable over a long period of time and also help this product attain Food Drug Administration Approval which can help in the food industry. HDPE Sheet is very economical and can provide an engineering plastic with equal or greater performance advantages and save end users a significant amount of money.

- Q: Can plastic sheets be used for noise reduction barriers?

- Yes, plastic sheets can be used for noise reduction barriers. They can effectively block and absorb sound waves, making them suitable for creating barriers that reduce noise levels in various environments. Plastic sheets with sound-absorbing properties are often used in construction, industrial settings, and even in residential areas to minimize noise pollution.

- Q: Can plastic sheets be used for lampshade replacements?

- Yes, plastic sheets can be used as lampshade replacements. They are a versatile and cost-effective alternative to traditional lampshade materials like fabric or glass. Plastic sheets are lightweight, durable, and come in different colors and patterns, allowing for various design possibilities. However, it is important to ensure that the plastic used is fire-resistant and compatible with the lamp's heat output to ensure safety.

- Q: Are plastic sheets resistant to chemicals used in automotive fluids?

- Yes, plastic sheets are generally resistant to chemicals used in automotive fluids.

- Q: What are the different types of plastic sheets available?

- There are several different types of plastic sheets available, including acrylic sheets, polycarbonate sheets, PVC sheets, PETG sheets, and HDPE sheets, each with their own unique properties and applications.

- Q: Can plastic sheets be used for greenhouse roofing extensions?

- Yes, plastic sheets can be used for greenhouse roofing extensions. Plastic sheets, such as polycarbonate or polyethylene, are commonly used as a cost-effective and durable solution for greenhouse roofing. They provide insulation, light transmission, and protection against the elements, making them a popular choice for extending greenhouse roofs.

- Q: Are plastic sheets UV-resistant?

- Yes, plastic sheets can be made UV-resistant by incorporating specific additives during the manufacturing process. These additives protect the plastic from the damaging effects of ultraviolet (UV) radiation, helping to prevent discoloration, degradation, and loss of strength.

- Q: Can plastic sheets be used for protective barriers?

- Yes, plastic sheets can be used for protective barriers. They are often used as a cost-effective and versatile solution to protect against physical, chemical, or biological hazards. Plastic sheets can offer transparent visibility, resistance to impact, and easy installation, making them suitable for various applications such as in healthcare settings, construction sites, or industrial environments.

- Q: I have already asked a couple questions about this, and just need to know 2 more things. I know plastic wrap will work, but this is plastic sheet, and is much better,stronger and will still let light in correct? And for a greenhouse, does there need to be a few holes in the walls and roof to let air through, or should it be basically sealed completely? Thanks for any help!

- don't poke or cut hole in plastic, it will make a weak point that will tear. heavy plastic sheeting tears. you do need to vent the house though frame some openings at one peak near top and corresponding hole near bottom on other end. cover both openings with screen or hardware cloth to kep critters out.

Send your message to us

3mm Corrugated Polypropylene Plastic Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords