350mm Graphite Electrode for Producing Alloy Steels

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Graphite Electrode for Proudcing Alloy Steels

Composite of Graphite Electrode for Proudcing Alloy Steels

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke

and widely used in the electric arc furnaces for production of alloy steels, metal and other

nonmetallic materials, etc.

The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to 700mm.

Applications of Graphite Electrode for Proudcing Alloy Steels:

It is used for the electric arc furnace steel making. (About 70-80% graphite electrode is used for steel making).

It is used for the submerged arc furnace, including melting iron alloy, pure silicon, yellow

phosphorus,matte, calcium carbide and so on.

It is used for the resistance furnace, such as the graphite making, melting glass, silicon carbide

making and so on.

Advantages of Graphite Electrode for Proudcing Alloy Steels:

low electric resistance

good electric and thermal conductivity

high oxidation resistance

high mechanical strength

high machining accuracy

greater resistance to thermal and mechanical shock

28 drums counter-flow calcining furnace

Auto-control dosing system

Germany Enrich kneading system

3500MT vertical tamping&horizontal extruding press

Auto-comtrol ring backing furnace

Germany Feist-incon 2nd Baking Kiln

High pressure imprgnation system

Acheson high power DC graphitizing furnace

Japan Nachi NC electrode machining line

America lngersoll NC electrode machine line

Japan Nachi NC nipple machining line

Carbon fiber production line

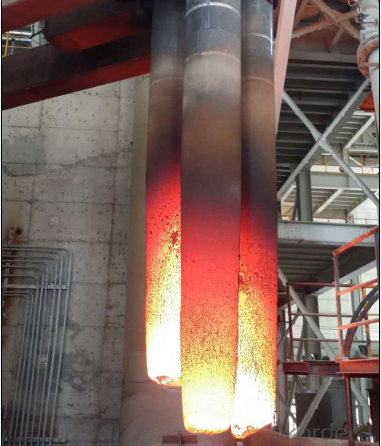

Graphite Electrode for Proudcing Alloy Steels Images

Specifications of Graphite Electrode for Proudcing Alloy Steels:

Item | Unit | Regular-power | Impregnated | ||||||

φ75- | φ150- | φ250- | φ350- | φ75- | φ250- | φ400- | |||

130 | 225 | 300 | 500 | 200 | 350 | 500 | |||

Specific Resistance (≤) | E | μ Ω·m | 8.5 | 9 | 9 | 9 | 8 | 8 | 8 |

N | 8 | 8 | 8 | 8 | 7.5 | 7.5 | 7.5 | ||

Bending Strength (≥) | E | MPa | 9.8 | 9.8 | 7.8 | 6.4 | 10 | 9 | 8 |

N | 13 | 13 | 13 | 13 | 15 | 15 | 15 | ||

Elastic Modulus (≤) | E | GPa | 9.3 | 9.3 | 9.3 | 9.3 | 12 | 12 | 12 |

N | 14 | 14 | 14 | 14 | 14 | 14 | 14 | ||

Bulk Density (≥) | E | g/cm3 | 1.58 | 1.52 | 1.52 | 1.52 | 1.58 | 1.58 | 1.58 |

N | 1.63 | 1.63 | 1.68 | 1.68 | 1.68 | 1.68 | 1.68 | ||

C.T.E.(≤) | E | 10-6/°C | 2.9 | 2.9 | 2.9 | 2.9 | 2.7 | 2.7 | 2.7 |

(100-600°C) | |||||||||

| N | 2.7 | 2.7 | 2.8 | 2.8 | 2.5 | 2.5 | 2.5 | |

Ash(≤) |

| % | 0.5 | 0.5 | 0.5 | 0.5 | 0.3 | 0.3 | 0.3 |

FAQ of Graphite Electrode for Proudcing Alloy Steels

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q9:Can U accept the detective of the third-party verification company ?

A:YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

If you have any enquiry,please don't hesitate to contact us, we will provide our best products and services for you!!

- Q: Graphite electrode specifications, graphite electrode manufacturers which good?

- Graphite electrode to Qingdao Chenyang graphite Co., quality assurance, trustworthy, we have been purchasing graphite electrode for them, you can ask them,

- Q: What is the role of the Pt electrode? What is the difference between the graphite electrode and the graphite electrode?

- Carbon electrodes, however, are less likely to be less controllable because of their microstructure, or have some effect on the electric field, if they are sensitive signals

- Q: Is the anode of electrolytic water suitable for ordinary titanium wires?

- Graphite firstFirst of all, the titanium electrode is usually not pure titanium, it should be titanium with a metal oxide coating. Secondly, the advantages of the titanium electrode is mainly to save electricity, the corrosion resistance of carbon is much stronger than that of industrial production, if the meaning is relatively large, but it is still in laboratory experiments, electrolysis of water, not what meaning.

- Q: What kind of asphalt is better for natural graphite coating?

- The graphite electrode includes: (1) ordinary power graphite electrode. Allows the use of current density below 17A / cm 2 graphite electrode, mainly used for steelmaking, smelting silicon, refining yellow phosphorus, such as ordinary power furnace. (2) oxidation resistance coating graphite electrode. A graphite electrode coated with an antioxidant protective layer is applied to form a protective layer that is conductive and resistant to oxidation at high temperature, thereby reducing electrode consumption during steelmaking. (3) high power graphite electrode. A graphite electrode with a current density of 18 ~ 25A / cm 2 is allowed to be used as a high power arc furnace for steelmaking. (4) ultra high power graphite electrode. Permits use of graphite electrodes with current densities greater than 25A / cm 2. Mainly used in ultra high power steelmaking arc furnace.

- Q: Classification of graphite electrodes

- A graphite electrode coated with an antioxidant protective layer (graphite electrode, antioxidant). The utility model has the advantages of forming a protective layer capable of conducting electricity and resisting oxidation at high temperature, reducing electrode consumption (19%~50%) during the steelmaking process of the poly carbon graphite electrode, prolonging the service life of the electrode (22%~60%), and reducing the electric energy consumption of the electrode. The popularization and use of this technology can bring about such economic and social effects:The unit consumption of graphite electrode is less, and the production cost is reduced.The power consumption of the graphite electrode is less, the energy consumption per unit of steelmaking is saved, the production cost is saved, and the energy saving is saved.Because the number of graphite electrodes is changed less, the labor quantity and danger coefficient of operators are reduced, and the production efficiency is improved.Graphite electrode is a kind of low consumption and low pollution product. It has a very important social significance in today's energy saving, emission reduction and environmental protection.

- Q: What are the factors that affect the electrode wear rate of machine tools?

- Influence of pulse interval on electrode wear. When the pulse interval is large, the electrode loss increases, which is due to the deterioration of the thermal effect condition and the damage of the "covering effect".

- Q: Jiqiu conductive graphite electrode, how to compare with copper is relatively large resistance value?

- This is not a good estimate of the sheet graphite resistance after 5mm

- Q: I used 12V direct current, graphite electrode electrolysis sodium sulfide solution, the anode produced a large number of black material, this is why ah?

- Is this principle. Graphite is a layer, each layer, each carbon is SP2 hybrid, and around three carbon connected, finally, between layer and layer formed delocalized covalent bond, making layer and layer can be connected. However, the delocalized covalent bond is not very stable, in attracting Yang Jizheng charge, delocalized covalent bond will certain destruction, the force between the graphite layer and the layer becomes small or not, so as to open.The black stuff is graphite

- Q: What is the composition of petroleum coke and what is its use?

- Petroleum coke can be used for the manufacture of graphite, smelting and chemical industries, depending on its quality. For example, the quality of cooked sweet coke coke, mainly used in the manufacture of ultra high power graphite electrode and some special carbon products; needle coke in steelmaking industry is an important material new technology development of EAF steelmaking.

- Q: How large is the permissible overload current per square millimeter of the graphite electrode cross section?

- 9A/mm2 safety current should be bare overhead, 5A/mm2 is obviously insulation lines, the indoor environment standards.

Send your message to us

350mm Graphite Electrode for Producing Alloy Steels

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches