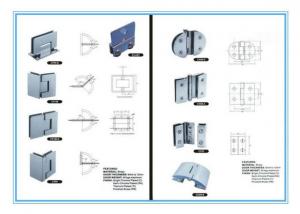

304 Stainless Steel Railings Glass Clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Pieces pc

- Supply Capability:

- 10000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of 304 Stainless Steel Railings 6MM Glass Clamp

1.material:304 316

2.size:1/2"-6"

3.free samples

Specification of 304 Stainless Steel Railings 6MM Glass Clamp

1.Precision Investment Casting: Silcon Sol Process

2.CNC Precised Machined

3.Quality Control: Spectrograph "Q4 TASMAN" Technology from Germany

4.Strong R&H Dept. Stuff: Welcome customized reducing order!!!!!!

5.Samples: with free samples

Trade Terms:

1.Payment Term: T/T or L/C

2.Date Of Delivery: Within 15-30 work days on the receipt of the customers deposit or l/c

3.Shipping Port: Qingdao Port

4.MOQ:10 Pieces

5.Production Capability: 120-180MT per month

6.R&H Dept. Stuff: Welcome customized reducing order!!!!!!

7.Samples: with free samples

Our Advantage of 304 Stainless Steel Railings 6MM Glass Clamp

1.Experience: we have 8 years Casting&Machined experience, and have first-class production line.

2.Precision Invest Casting: Wax:162 American Wax. Zircon powder&sand: imported from Australia

3.CNC Precised Machined: 2 Production Lines, including 2 CNC, 8 Automatic Lathes & 12 Manual Lathes

4.Quality Control: 4 QC, first-class Lab, Spectrograph "Q4 TASMAN" Technology from Germany

5.Strong Production Capability: 120-150MT per month

6.Strong R&D Capability: 7 tech. R&H engineers stuff, to deal with any reducing products, welcome customized order!!!

7.All of our products have passed by ISO9000:2008 and CE certificate quality test.

8.Professional Sale Stuff who can offer you best price, and sample with free.

9.Production Process of 304 Stainless Steel Railings 6MM Glass Clamp

10.Productive Technology: Precision Investment Casting (Silcon Sol Process)

11.Productive Process: Wax Mould-Shell Making-Dewaxing-Smelting&Casting-Shell Off-Blasting-Cutting&Polishing-Acid Washing-CNC Precised Machined

12.Quality Control: Spectrograph "Q4 TASMAN" Technology from Germany

- Q: (such as supplies, automotive accessories such as plastic plastic) LOGO technology company, who understand the general characteristics about this aspect, the amount of direct is to help guide a breakthrough point, mainly manifests in the company development business characteristics.

- such as the Great Wall automobile LOGO like the Great Wall, the merchants group LOGO as a "business". I hope to help you, I feel reasonable, give points!

- Q: There are equipment in the home, in principle, plastic or metal auto parts can be processed. Where can I pick up the list?

- How about your productivity?! What's the price?! Convenient and quick!

- Q: What is the 34 curtain pinch 6? I just know it's a mechanical finishing material

- 34CrNiMo6, Cr- Ni- Mo chromium nickel molybdenum, for high temperature and low temperature stainless steel fasteners

- Q: Jiangyin Milacron Plastics Machinery Co. Ltd.

- Jiangyin Milacron Plastics Machinery Co. Ltd. in June 18, 2004 by the United States and Jiangyin Milacron molding group joint venture, mainly by the United States to provide technical training and production of large-scale injection molding machine.

- Q: Plastic machinery industry in recent years, the output value? Import and export data? Preferably with industry analysis

- China's plastic machinery started in twentieth Century, in the late 50s, with the development of China's petrochemical industry, China's plastics machinery industry gradually formed an independent industrial sector, and began to take shape.In recent years, the plastic machinery industry has developed rapidly, the national plastics machinery manufacturing enterprises have developed to more than 1000, but with a certain size, strength of about 400 enterprises. China plastic machinery industry after "fifteen" to achieve leapfrog development, expand the industrial scale, the main economic indicators for eight consecutive years is increasing year by year, the top 194 industries for its development speed and the main economic indicators in the machinery industry under the jurisdiction of the.2006 Chinese plastics machinery manufacturing industry import and export totaled $2 billion 304 million, up 6.18% over the previous year. Among them, exports amounted to $586 million, an increase of 36.69%; imports amounted to $1 billion 718 million, down 1.32%. We can see that China machinery production and export capacity has been greatly improved.In 2006 1-12, China's total output of plastic processing equipment was 524588.49 tons, an increase of 32.47% compared with the same period of 2005. In 2007 1-6, China's total output of plastic processing equipment was 333164.36 tons, an increase of 32.87% compared with the same period of 2006.

- Q: Plastic machineryWhat about plastic machinery?

- Plastic machinery according to the production process of plastic products, plastic machinery can be divided into plastic mixing machinery, plastic forming machinery, plastic twoSub processing machinery and plastic processing, auxiliary machinery or devices, such as four major categories. Plastic compounding machine for all kinds of plastic mixing manufacturing, including kneading machine, plastic refining machine (mixing machine and mixer), granulator, crusher and screening machine, grinding machine etc..

- Q: What accessories does PPS engineering plastics use on the car?

- Polyphenylene sulfide (or poly phenylene sulfide)[PPS] is a crystalline polymer, which is the lowest price in high temperature engineering plastics and can be molded by thermoplastic processing method. Its typical product is called "Ryton" (Phillips products).PPS 55%-65% is a high degree of crystallinity, rigid white powder polymer, high heat resistance, mechanical strength, rigidity, flame resistance, chemical resistance, dimensional stability, resin has excellent electrical properties, abrasion resistance, creep resistance and excellent flame retardancy. Self extinguishing. Up to UL94V-0, good electrical performance is maintained under high temperature and high humidity. Good liquidity, easy to shape, almost no shrinkage hole when forming. It has good affinity with various inorganic fillers. Enhanced after modification can improve the physical and mechanical = if the mechanical properties and heat resistance (heat distortion temperature), reinforced with glass fiber, carbon fiber, aramid fiber, metal fiber, glass fiber. Inorganic filling materials are talc, kaolin, calcium carbonate, silica, molybdenum disulfide and so on.

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2010 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | 40.00% North America 15.00% Mid East 10.00% Northern Europe 10.00% Southeast Asia 10.00% South America 5.00% South Asia 5.00% Western Europe 5.00% Eastern Europe |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | QINGDAO PORT,TIANJIN PORT |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | average |

Send your message to us

304 Stainless Steel Railings Glass Clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Pieces pc

- Supply Capability:

- 10000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords