304 Cold Rolled Stainless Steel for Bulidings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:304/304L/316/316L/321/409/409L/410/410S/430

Type:Stainless Steel Strips

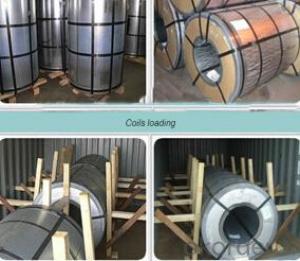

Shape:Coil

Grade:300 Series

Certification:ISO, SGS

Perforated:Not Perforated

Standard:ASTM, AISI, GB, JIS, DIN, EN

Technique:Cold Rolled

Surface Treatment:Bright

Surface:2D,2e,2b,2bb,Sb,No.4,Ba,Hl,6k,7k,8k

Width:1000mm/1219mm/1250mm/1500mm/1524mm/1829mm/2000mm

Thinckness:0.3mm to 6mm

Edge:Silt/Mill Edge

Export Markets:Global

Product Description

The detail specification of cold rolled stainless steel coils are as below:

| Grade: | 201/202/301/304/304L/316/316L/317L/321/409/409L/410/410S/430/439 |

| Standard: | ASTM,AISI,JIS,EN,DIN,GB |

| Surface: | 2D,2E,2B,2BB,SB,NO.4,BA,HL,6K,7K,8K |

| Width: | 1000mm/1219mm/1250mm/1500mm/1524mm/1829mm/2000mm |

| Thickness: | 0.3mm to 6mm |

| Edge: | Slit/Mill Edge |

| Origin: | TISCO,POSCO,LISCO,JISCO,BAOSTEEL,Baoxin,Eastern Special Steel and so on |

| Productivity: | 10000MT/Mont |

| MOQ: | 30mont |

| Payment Term: | TT,L/C at sight/, L/C 30,60,90,180 days,WEST UNION |

| Price Term: | FOB/CFR/CIF Ningbo,Shanghai,Tianjin,Shenzhen Port |

| Delivery: | 7-10 days after receive buyer's advance deposit or LC copy |

| Packaging: | Seaworthy Export Standard Package.Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might otherwise be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information. |

| Detail Application: | construction field;ship building industry;petroleum and chemical industries;war and electricity industries;food processing and medical industry; boiler heat exchanger; machinery and hardware industry |

Technical notes:

| Surface Finish | Definition | Application |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

| 2D | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment. | Construction Material, heat exchanger,exhaust pipe |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| No.8 | A highly reflective finish obtained by polishing with successively finer abrasive and buffing extensively free of grit lines | Indoor decoration & Reflector, Hospital Equipment |

Our Advantages

All products are made of high-quality imported raw materials.

Excellent shipment after-sales service & Prompt

The Authorized agent of TISCO,JIISCO,the stainless steel distributor of BOSTEEL,ZPSS,LISCO and also can get the resources from all the stainless steel mills in China.

Have own processing and distribution center & can take the orders according to customers' requirements.

The transport in Hangzhou is very convenient & nearby Shanghai and Ningbo Port.

Our products are certified by ISO9001:2008 authentication quality systems.

Quick Response to Your Enquiry.

- Q: I have never owned a non-stainless steel chef's knife and have been looking at some to buy recently, but all of them have various degrees of wear and use. They say that the wear is normal for non-stainless steel knives, but how can I tell if it is too much wear, or if the blade is clean?

- Carbon steel chef's knives out perform stainless in every aspect except 1, care. You can't put them in a dishwasher. Wash, rinse and dry off. Do not keep them in a drawer filled with other kitchen stuff, rather, keep them in a cabinet or block. If it starts to rust you can use steel wool to clean them up, or fine grit sandpaper if you want to retain a fine finish. For your viewing pleasure, a chef's knife I forged from crane cable.

- Q: did bible stated that steel is coming from outer space. i mean meteor rocks that enter our earth sistem contains the minerals iron.

- If you are using either an NAB or RSV translation of the Bible, steel is only mentioned once in the Bible. Compare Nahum 2:4 (NAB) and Sirach 31:26 (RSV). There is no reference of an outer space in the Bible. Furnace is mentioned in Sirach. It takes a lot of energy to mix Iron and Carbon to produce steel. The alloy can only be produced in the furnace at an extremely high temperature.

- Q: What are the different types of steel surface treatments for coils?

- There are several types of steel surface treatments for coils, including galvanizing, electroplating, powder coating, and painting.

- Q: What bike companies make the best Steel Road bikes?

- Giant brand road bikes

- Q: What is current price of steel in US market?

- here okorder /

- Q: What are the common methods of joining steel coils?

- There are several common methods used for joining steel coils, depending on the specific application and desired outcome. 1. Butt welding: This is a commonly used method where the two ends of the steel coils are aligned and welded together. Butt welding can be done using various techniques such as gas welding, electric resistance welding, or laser welding. This results in a strong and continuous joint without any additional material. 2. Overlapping and stitching: In this method, one end of the steel coil is overlapped onto the other end, and then stitched together using mechanical fasteners like staples, nails, or screws. This technique is suitable for temporary or low-stress applications where disassembly may be required. 3. Mechanical coupling: Steel coils can also be joined using mechanical couplings. These couplings are typically designed to fit over the ends of the coils and securely hold them together. Mechanical couplings are commonly used in pipelines, where the joint needs to be leak-proof and withstand high pressure. 4. Adhesive bonding: Another method of joining steel coils is through the use of adhesives. This involves applying a suitable adhesive or bonding agent to the ends of the coils and then pressing them together. Adhesive bonding allows for a clean and aesthetically pleasing joint, but its strength may vary depending on the adhesive used. 5. Overlapping and welding: Similar to overlapping and stitching, this method involves overlapping the ends of the steel coils and then welding them together. However, instead of using mechanical fasteners, welding is used to create a stronger and more permanent joint. This method is commonly used in structural applications where high strength and durability are required. It is important to note that the choice of joining method depends on factors such as the type of steel, the application requirements, and the desired strength of the joint. Proper consideration should be given to ensure the selected method is suitable for the specific project.

- Q: How are steel coils used in the production of signage?

- Steel coils are used in the production of signage by being cut into sheets and then shaped into various sign components. These coils provide a durable and rigid material that can be easily manipulated and formed into different shapes, allowing for the creation of sturdy and long-lasting signs.

- Q: How are steel coils used in the manufacturing of industrial conveyors?

- Steel coils are used in the manufacturing of industrial conveyors as the primary material for the conveyor belts. They are formed into circular shapes and then cut into strips to create the belt. Steel coils provide strength, durability, and flexibility to the conveyor belts, allowing them to withstand heavy loads and operate smoothly.

- Q: I completed the missions in broken steel like: the one of the rangers, the one of vault 101, the one of the enclave, and several others.are there any more INTERESTING missions?

- one good mission is stealing independence given in rivet city

- Q: What are the common applications of cold-rolled stainless steel coils?

- Due to their unique characteristics and versatility, cold-rolled stainless steel coils find widespread use in various industries. The following are some common applications of these coils: 1. Automotive Industry: Manufacturing parts like exhaust systems, trim, and body panels in the automotive industry extensively utilize cold-rolled stainless steel coils. The corrosion resistance and aesthetic appeal of stainless steel make it an ideal choice for these purposes. 2. Construction Industry: The construction industry heavily relies on stainless steel coils for roofing, cladding, and structural components. The durability, strength, and resistance to corrosion of cold-rolled stainless steel coils make them a preferred material in building and infrastructure projects. 3. Kitchen Appliances: Kitchen appliances such as refrigerators, ovens, and dishwashers commonly incorporate stainless steel coils. The hygienic properties, easy maintenance, and sleek appearance of stainless steel make it popular for these applications. 4. Food Processing Industry: In the food processing industry, cold-rolled stainless steel coils are extensively used due to their non-reactive nature and resistance to corrosion. These coils are used for manufacturing equipment, storage tanks, and conveyor systems in food processing plants. 5. Medical Equipment: Cold-rolled stainless steel coils are widely employed in the medical industry for manufacturing surgical instruments, implants, and medical devices. The biocompatibility, strength, and resistance to corrosion of stainless steel make it suitable for these critical applications. 6. Oil and Gas Industry: The oil and gas industry utilizes cold-rolled stainless steel coils in various applications, including pipelines, storage tanks, and offshore platforms. The high resistance to corrosion and extreme temperature conditions make stainless steel a reliable choice in this demanding industry. 7. Aerospace Industry: Stainless steel coils find use in the aerospace industry for manufacturing aircraft components, engine parts, and structural elements. The lightweight yet high-strength properties of stainless steel make it an ideal material for these applications. In summary, cold-rolled stainless steel coils have diverse applications across industries such as automotive, construction, kitchen appliances, food processing, medical, oil and gas, and aerospace. The unique combination of durability, corrosion resistance, strength, and aesthetic appeal makes stainless steel coils a preferred choice in various industrial sectors.

Send your message to us

304 Cold Rolled Stainless Steel for Bulidings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords