3/8 Aluminum Coil - Mill Finished Direct Casting Aluminum Circle AA1050

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of DC Aluminium in Coil Form for making Aluminium Circle Description

DC Aluminium in Coil Form for making Aluminium Circle is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Feature of DC Aluminium in Coil Form for making Aluminium Circle

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

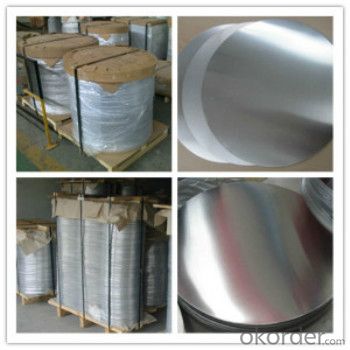

3. Image of DC Aluminium in Coil Form for making Aluminium Circle

4. Specification of DC Aluminium in Coil Form for making Aluminium Circle

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

5. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

4)What about payment term?

30% T/T in advance, balance against B/L COPY or 100% L/C AT SIGHT.

- Q: Can aluminum coils be customized in terms of thickness?

- Yes, aluminum coils can be customized in terms of thickness. The thickness of aluminum coils can be modified through various manufacturing processes to meet specific requirements and applications.

- Q: so i've been using natural deodorants that don't have aluminum, but they only work for a little while. i've heard that aluminum may cause Alzheimer's, and i have a history of Alzheimer's. do you know of any web sights that can confirm/deny this? or if you know of any deodorants that work really well that don't have aluminum! this is really getting annoying

- aluminum isnt a harmful element unless its gets inside you

- Q: What are the common surface finishes for aluminum coils in the automotive industry?

- Aluminum coils are extensively utilized in the automotive sector for various purposes due to their lightweight, high strength, and resistance to corrosion. To safeguard them from environmental elements and improve their appearance, aluminum coils in the automotive industry often undergo surface treatments. Anodizing is one of the most prevalent surface treatments for aluminum coils in the automotive industry. It is an electrochemical process that forms a thin protective layer on the surface of the aluminum coil. This treatment not only offers excellent corrosion resistance but also allows for customization of colors, making it a popular choice for automotive applications. Anodized aluminum coils can be found in a variety of colors and finishes, adding aesthetic appeal to vehicles. Another commonly employed surface treatment for aluminum coils in the automotive industry is powder coating. This technique involves applying dry powder paint onto the aluminum coil's surface and then curing it under heat to create a durable and long-lasting finish. Powder coating provides exceptional resistance to chipping, scratching, and fading, making it ideal for automotive components exposed to harsh conditions that require high durability. Moreover, powder coating offers a wide range of color options, enabling manufacturers to achieve the desired aesthetic appearance. Additionally, aluminum coils in the automotive industry may undergo other surface treatments like laminating, painting, or polishing, depending on specific application requirements. Laminating involves bonding a thin protective film onto the surface of the aluminum coil to provide additional protection against abrasion and chemical exposure. Painting entails the application of liquid paint onto the aluminum coil's surface, allowing for customization and protection against corrosion. Polishing, on the other hand, is a mechanical process that enhances the surface smoothness and appearance of the aluminum coil, resulting in a reflective and glossy finish. To summarize, the automotive industry commonly employs surface treatments such as anodizing, powder coating, laminating, painting, and polishing for aluminum coils. These treatments not only enhance the appearance of the aluminum coils but also provide protection against corrosion, abrasion, and other environmental factors, making them indispensable in the manufacturing of automotive components.

- Q: What are the potential health hazards linked to the use of aluminum coils?

- <p>There are concerns about the use of aluminum coils due to the possibility of aluminum leaching into food during cooking. Aluminum has been linked to various health issues, including cognitive decline and Alzheimer's disease, although the evidence is not conclusive. Additionally, aluminum exposure may lead to bone and neurological disorders. However, the health risks associated with aluminum coils are still a subject of debate among researchers. It's recommended to minimize exposure to aluminum by using alternative cooking methods or materials, such as stainless steel or cast iron.</p>

- Q: How to calculate the weight of strips with the weight of aluminum coil known?

- Thickness*width*length=weight/density, length=weight/(density*thickness*width).Ps: Keep unit the same.

- Q: How do aluminum coils contribute to the insulation properties of products?

- The insulation properties of various products are greatly enhanced by aluminum coils, playing a crucial role. The utilization of aluminum coils in insulation systems leads to improved thermal efficiency, decreased heat transfer, and reduced energy consumption. To begin with, aluminum possesses excellent heat and electricity conducting abilities. This particular characteristic enables aluminum coils to distribute and dissipate heat effectively, preventing the transfer of thermal energy from one side of the product to the other. Consequently, aluminum coils act as a barrier, minimizing the loss or gain of heat, which is essential for maintaining optimal temperatures across different applications. Additionally, aluminum coils exhibit low thermal conductivity. This implies that they are not easily affected by temperature changes and do not efficiently transfer heat. As a result, products incorporating aluminum coils can better withstand external temperature fluctuations, providing superior insulation against hot or cold conditions. Moreover, aluminum coils are lightweight, allowing for easy handling and installation in various products. This lightweight attribute is advantageous as it does not impose significant weight on the overall structure, making it suitable for industries requiring portable or lightweight insulation solutions. Furthermore, aluminum possesses high resistance to corrosion, making it ideal for applications in humid or corrosive environments. This durability ensures that the insulation properties of products containing aluminum coils remain effective over an extended period, without deterioration or compromise in performance. Additionally, aluminum is a recyclable material, aligning with sustainable practices. The use of aluminum coils in insulation products promotes environmental consciousness by reducing waste and energy consumption associated with the manufacturing of new materials. In conclusion, aluminum coils contribute significantly to the insulation properties of products by effectively distributing and dissipating heat, minimizing heat transfer, and resisting temperature fluctuations. Their lightweight nature, durability, and recyclability further augment their effectiveness as an insulation component. Overall, aluminum coils represent a valuable addition to insulation systems, enhancing thermal efficiency and decreasing energy consumption.

- Q: How are aluminum coils used in the production of window frames?

- Aluminum coils are commonly used in the production of window frames due to their numerous advantages. These coils are typically made of high-quality aluminum alloy, which provides strength, durability, and resistance against corrosion. To begin the production of window frames, aluminum coils are first unrolled and cut into the desired lengths. These coils are available in various thicknesses, allowing manufacturers to produce window frames of different sizes and specifications. The aluminum coils are then shaped into the required profiles using specialized machines. These profiles can be extruded, bent, or rolled into different shapes, such as rectangular or curved, depending on the design of the window frame. This flexibility in shaping allows for the creation of custom window frames to meet specific architectural requirements. Once the profiles are formed, they are joined together using different techniques like welding or mechanical fasteners. The lightweight nature of aluminum makes it easy to handle during the assembly process, reducing overall production time and costs. Additionally, aluminum coils can be treated with various surface finishes, such as anodizing or powder coating, to enhance their aesthetics and provide further protection against weathering and wear. These finishes also offer a wide range of color options, allowing window frame manufacturers to match the frames with the overall design of the building or the homeowner's preferences. Using aluminum coils in window frame production offers several advantages. Aluminum is a highly sustainable material as it can be recycled repeatedly without losing its properties. It is also lightweight, making the installation process easier and reducing the load on the structure. Moreover, aluminum is a good thermal conductor, which helps in improving energy efficiency by minimizing heat transfer. In conclusion, aluminum coils play a crucial role in the production of window frames. Their strength, durability, flexibility, and aesthetic options make them a preferred choice for manufacturers. Whether it is for residential or commercial applications, aluminum coils provide high-quality window frames that meet industry standards and enhance the overall appearance and performance of buildings.

- Q: Aluminum roll, which companies are used?

- Too many things that you can see every day, with all the things that are made of aluminum, and the companies that make these aluminum products are useful, so it's unclear!

- Q: Some manufactures (Kia, Hundai) use Iron blockswhileOther manufactures (Nissan, Chevy, ect.) use Aluminum blocks*****Is the point of using Iron blocks to increase long-term durability or temperature endurance??ORIs the use of Iron blocks simply an older, simpler technology (as compared to using Aluminum), the manufacture of which costs less money??And you would think that Aluminum weight savings would transer to better MPG, but the Kia gets very comparable mileage anyway.Thank you

- Aluminum's main advantages are weight and increased mpg for CAFE regulations. If you are going to keep your car to 150,000 miles eitheir block material will do. But if you are going to keep it 300,000 to the bitter, bitter end, you are better off with iron.

- Q: How are aluminum coils manufactured?

- Aluminum coils are typically manufactured through a process called continuous casting and cold rolling. In this process, molten aluminum is poured into a mold to form a solid slab. The slab is then passed through a series of rolling mills to reduce its thickness and achieve the desired gauge. This rolling process is repeated several times until the desired thickness and surface finish are achieved. The coils are then cooled, trimmed, and packaged for distribution.

Send your message to us

3/8 Aluminum Coil - Mill Finished Direct Casting Aluminum Circle AA1050

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords