254SMO stainless steel forgings/round bar/rod/pipe fittings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless steel bars,profiles,beams

Product Information:

(Physical Properties)

Density | 8.24g/cm3 |

Fusion Point | 1320-1390°C |

Standard:ASTM A182 | |

Mechanical Property

Alloy and state | Tensile Strength | Yield Strength | Elongation | Hardness |

RM N/MM2 | RP0.2N/MM2 | A5% | HB | |

Thin plate/strips | >=690 | >=310 | ó=35 | <=223< span=""> |

Sheet | >=655 | >=310 | ó=35 | <=223< span=""> |

254SMO Application field:

1.Petroleum, petrochemical equipment, such as the petrochemical equipment in the corrugated pipe

2. Pulp bleaching equipment, such as pulp digester, bleaching equipment, filter scrubber for bucket cylinder and pressure roller, etc..

3. Power plant flue gas desulfurization device, the main use of the site: absorption tower tower body, flue, block door, inside, spray system, etc..

4.Marine systems or sea water treatment, such as the power plant in the use of seawater cooling of thin walled condensate pipeline, seawater desalination processing equipment, even in the sea may not flow equipment can also be used.

5. Desalination industry, such as salt or desalination equipment

6. Heat exchangers, especially in the working environment of chlorine ion exchanger.

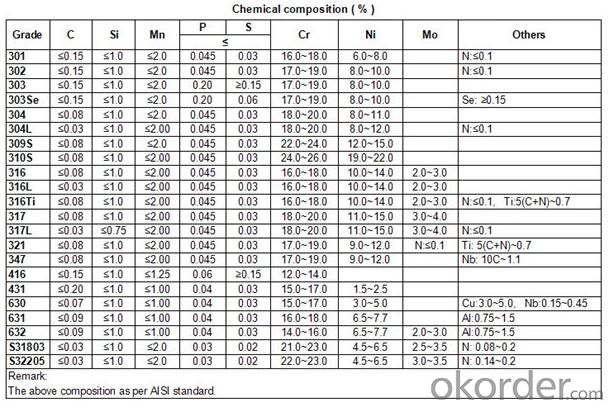

| 200 series: 201, 202 | |

| 300 series: 303, 304, 304L,321, 310S, 316, 316L | |

| 400 series: 410, 420, 430 | |

| Standard | AISI, ASTM, DIN, GB, JIS, SUS |

| Diameter | 2mm-300mm |

| Length | 1 meters to 9 meters or random |

| Surface | bright, black |

| Treatment | Hot rolled, cold drawn, Annealed, Grinding |

| Packing | Standard sea-worthy package or as required |

| Trade Terms | EXW, FOB, CFR, CIF |

| MOQ | 200 KGs Stainless Steel Round Bar |

| Payment | 30% deposit in advance, balance against copy of BL or irrevocable L/C at sight |

| Delivery | Usually 15-20 days upon receipt of deposit for 1 FCL |

Product Size Detail:

| Main operation | Main steel grade | Available size(mm) | Monthly capacity(mt) | Length(mm) | ||

| OEM | Stainless steel | 40~500 | 1500 | 4000~8000 | ||

| Hot | 303 303Cu 304/L 310S 316/L 321 416 420 | 12 ~200 | 3000 | 4000~7000 | ||

| 17-4PH WLA510 | ||||||

| ST Bar | 321 304/L 316/L 310S 17-4PH WLA510 | 19~110 | 2000 | 4000~7000 | ||

CD Bar | Round bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | |

| Square bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| Hex bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| CG Bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | ||

Specificate:

Our Advantages

• All products are made of high-quality imported raw materials.

• Our products are certified by ISO9001:2008 authentication quality systems.

• we are nominated as the AAA enterprise by Jiangsu government.

• Quick Response to Your Enquiry.

- Q: Can stainless steel bars be used in the water treatment repair industry?

- Yes, stainless steel bars can be used in the water treatment repair industry. Stainless steel is a highly corrosion-resistant material, making it ideal for use in environments where it may come into contact with water, chemicals, and other corrosive substances. In the water treatment repair industry, stainless steel bars can be used for various applications such as building or repairing water treatment equipment, pipelines, tanks, and structures. They provide excellent strength and durability, ensuring long-lasting performance and resistance to rust and corrosion. Additionally, stainless steel bars can withstand high temperatures and maintain their integrity, making them suitable for use in different water treatment processes.

- Q: What are the different surface coatings available for stainless steel bars?

- Stainless steel bars have various surface coatings available, each with their own unique properties and benefits. Some commonly used coatings include: 1. Passivation: By treating the stainless steel surface with an acid solution, iron contaminants are removed and a passive oxide layer is formed. This process improves the corrosion resistance of the bars. 2. Electropolishing: Through an electrochemical process, a thin layer of material is removed from the surface, resulting in a smooth and shiny finish. Electropolishing not only enhances the appearance but also reduces the risk of corrosion by eliminating surface imperfections. 3. Powder coating: Dry powder is applied to the bars and then cured with heat to create a protective layer. This coating offers excellent resistance to corrosion, chemicals, and UV radiation, making it suitable for outdoor applications. 4. PVD coating: Physical Vapor Deposition (PVD) is a vacuum deposition process that produces a thin film of coating on the surface. PVD coatings can provide enhanced hardness, wear resistance, and improved aesthetics. 5. Paint coating: Stainless steel bars can be coated with paint, adding color and providing protection against corrosion. Paint coatings come in a wide range of colors and can be customized to meet specific requirements. 6. Anodizing: Although primarily used for aluminum, anodizing can also be applied to stainless steel bars. This process creates an oxidized layer on the surface, enhancing corrosion resistance and providing decorative finishes in various colors. 7. Ceramic coating: Ceramic coatings offer high-temperature resistance, excellent hardness, and low friction properties. They protect stainless steel bars from wear, corrosion, and chemical damage, making them suitable for harsh environments. To determine the most suitable surface coating for stainless steel bars, it is essential to consider the specific requirements of the application and consult with experts.

- Q: Are stainless steel bars magnetic?

- The composition of stainless steel bars determines whether they are magnetic or non-magnetic. In general, stainless steel is not magnetic. Nevertheless, some stainless steel types, like the 400 series, can be magnetic because of the presence of ferrite in their microstructure. Conversely, austenitic stainless steel, which is the most prevalent type, is non-magnetic due to its face-centered cubic structure that does not permit magnetic field alignment. Therefore, if you are searching for magnetic stainless steel bars, it is crucial to verify the grade or type being utilized.

- Q: Are stainless steel bars suitable for architectural canopies?

- Architectural canopies can be effectively constructed using stainless steel bars. Stainless steel possesses qualities such as durability, resistance to corrosion, and aesthetic appeal, which make it an ideal material for architectural applications. Even when exposed to various weather conditions like rain, snow, or extreme temperatures, stainless steel bars remain rust-free and do not deteriorate. Moreover, stainless steel bars can easily be shaped and sized to create intricate and visually pleasing canopy designs. The sleek and modern appearance of stainless steel adds to the architectural aesthetics of a structure, making it a popular choice for canopies in commercial, residential, and public spaces. In summary, stainless steel bars provide a combination of strength, durability, and aesthetics, making them highly suitable for architectural canopies.

- Q: 2Cr13 what's the use of stainless steel bars?

- Commonly known as stainless iron, low density, hardness, not easy to rust, we used this material made low pressure storage tank, also made big pipe fittings, other uses are not clear.

- Q: Can stainless steel bars be used in the agricultural industry?

- Certainly, the agricultural industry can make use of stainless steel bars. Stainless steel, being a versatile and resilient material, brings numerous advantages to agricultural applications. It possesses corrosion resistance, making it especially valuable in environments that have high levels of moisture or are exposed to chemicals and fertilizers. Stainless steel bars have the potential to be employed in a diverse range of agricultural equipment, machinery, and infrastructure, including barns, animal enclosures, gates, fences, and irrigation systems. Furthermore, stainless steel bars are easily maintained, cleaned, and sanitized, rendering them highly suitable for use in food processing and storage facilities within the agricultural sector.

- Q: Are stainless steel bars suitable for pharmaceutical packaging equipment?

- Yes, stainless steel bars are suitable for pharmaceutical packaging equipment. Stainless steel is known for its corrosion resistance, strength, and hygienic properties, making it an ideal material choice for equipment used in pharmaceutical packaging. It ensures that the packaging process remains sanitary, protects the integrity of the pharmaceutical products, and complies with the stringent standards and regulations of the industry.

- Q: Can stainless steel bars be hardened by cold working?

- Indeed, cold working is capable of hardening stainless steel bars. This process involves deforming the metal grains at room temperature, eliminating the need for heating. Cold working can be accomplished through various techniques, including rolling, drawing, or bending. In the cold working of stainless steel bars, the crystal lattice structure experiences dislocation due to the deformation of the metal grains. This dislocation leads to an increase in the hardness and strength of the material. Moreover, cold working introduces strain into the metal, further enhancing its mechanical properties. It is worth noting that the extent of hardening achieved through cold working depends on several factors. These factors include the initial composition and grade of the stainless steel, the amount of deformation applied, and the specific cold working method utilized. Furthermore, it is important to mention that certain stainless steel grades with high levels of austenite, such as the 300 series, may have limitations on the hardening effect of cold working. Overall, cold working proves to be an effective approach for hardening stainless steel bars. It yields improved mechanical properties and increased strength.

- Q: Are stainless steel bars suitable for welding?

- Stainless steel bars are indeed appropriate for welding due to their excellent weldability. This quality makes stainless steel a favored option for numerous welding tasks. The presence of a high chromium content in stainless steel aids in its protection against corrosion and offers impressive heat resistance. Nonetheless, it is crucial to employ suitable welding techniques and equipment to achieve successful welds. This includes utilizing low heat inputs, selecting the appropriate filler material, and ensuring proper shielding gas. Moreover, stainless steel bars are available in multiple grades, each with unique welding characteristics, emphasizing the importance of choosing the correct grade for the intended welding application.

- Q: Are stainless steel bars suitable for chemical storage tanks?

- Indeed, stainless steel bars prove to be a fitting choice for chemical storage tanks. Renowned for its remarkable corrosion resistance attributes, stainless steel emerges as the perfect candidate for chemical storage. It exhibits resistance towards both organic and inorganic chemicals, encompassing acids, alkalies, and solvents. Moreover, stainless steel bars furnish the essential strength and structural soundness crucial for enduring the weight and pressure exerted by the stored chemicals. Furthermore, stainless steel's ease of cleansing, smooth surface that mitigates contamination risks, and lengthy lifespan further solidify its reputation as a dependable option for chemical storage tanks.

Send your message to us

254SMO stainless steel forgings/round bar/rod/pipe fittings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords