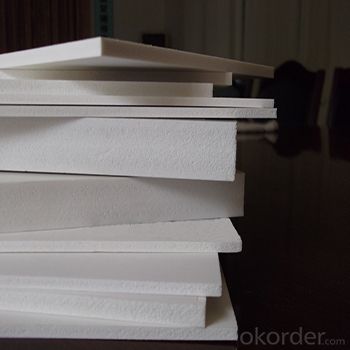

2024 New Factory Manufacture PVC Foam Board Machine for Plastic Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated and Insulation. .

5. Dampproof and Anti - deformed.

6. Non-corrosion and Non-toxic.

7. Tough, rigid with the high impact strength.

8. Stable color retention.

Specifications:

1 Width: 1220mm or as your requirement

2 Length: 2440mm or as per your requirement

3 Thickness: From 1mm to 30mm

4 Density: from 0.3 to 0.6

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection.

Parameter

| Products Name | pvc foam board machine |

| Main Material | PVC powder |

| Surface Treatment | As per your request |

| Color | White and so on |

| Certificate | SGS,3C,RoHs, ISO |

| Payment | 30% deposit, 70% balance before shipment. T/T W/U M/G |

| Packing | Carton box or wooden pallet packing. |

FAQ:

Q1: What are your product ranges? Where is your market?

A1: we are manufacturer specializing in stationery and plastic packing products in highly quality

and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,

packages of cosmetic and other daily necessities.

Q2: If the products have some quality problem ,how will you deal with it?

A2: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind. Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q3: Is free design assistance available for clients?

A3: If you have problems in designing or beautifying the customized product, we will offer you the best design assistance.

Q4: What factors affect the price?

A4: Style, material, dimension, quantity, logo etc.AS for your inquiry, try to give us all these information toget exact quotation.

- Q: I want to know if it is durable, and transmit light. I want to use it for my green house, but, it has to be a thick plastic but not light obscuring.

- 6 Mil Plastic

- Q: What are the different ways to join plastic sheets together?

- There are several different ways to join plastic sheets together, including adhesive bonding, thermal welding, mechanical fastening, solvent bonding, and ultrasonic welding.

- Q: Can plastic sheets be used for automotive applications?

- Yes, plastic sheets can be used for automotive applications. They are commonly used for interior components such as dashboards, door panels, and seat backs. Additionally, plastic sheets are used for exterior parts like fenders, bumpers, and trims. Plastic sheets offer advantages such as lightweight, durability, and flexibility, making them suitable for various automotive applications.

- Q: I need a FULL size plastic sheet for an adult size bed (not a crib). I've looked at my local stores like WalMart but can't find them anywhere. I'm not looking for a link to a site where I can order them. I need to go pick one up today to have it for immediate use.Thank you

- Rather than a plastic or rubber sheet...try this. Call them, they probably have an alternative mattress cover, not this exact one, but similar. It isn't as hot to sleep on and yet it will protect against accidents.

- Q: How do plastic sheets compare to acrylic sheets?

- Plastic sheets and acrylic sheets are similar in many ways, as acrylic is actually a type of plastic. However, acrylic sheets have distinct advantages over other types of plastic sheets. Acrylic sheets are more transparent, offer better clarity, and have higher overall strength and durability than most plastic sheets. Additionally, acrylic sheets are more resistant to UV rays, weathering, and impact. They are also easier to shape, cut, and manipulate, making them a popular choice for various applications such as signage, displays, and protective barriers.

- Q: is 3.5 mil thick plastic sheeting thick enough to use for a backyard ice rink?

- That should be fine. It's not the plastic, its the temperature. If its cold enough, the water will freeze even if you just flood the grass, on a cheap tarp, etc.

- Q: I got, what I thought was a great deal on photo albums. When I got them home, I discovered they are only plastic envelope type pages. After reading the covers on the albums, it says clearly says sheet protectors, so what do I need to purchase to stick my pictures on to put into these plastic sheets?I am new at scrapbooking and photo album placements!!!!

- Yes, if the work is still copyrighted (they eventually expire) then the copyright owners have the exclusive right to make copies or derivative works (transcribing it into other forms), as well as distribution or public performances, subject to certain limitations. One of those limitations is called fair use, often involving private use without any commercial gain or private profit. The mere photocopying is technically illegal, as it simply displaces the copy you SHOULD have purchased from the authorized distributors. Someone already mentioned one other exemption that involves educational use in a classroom of a non-profit school, provided the other limitations are met. Even if you go to a public library, there must be signs on the photocopy machines that instruct you about the basics of copyright law and remind you that not all copying is allowed. As for including the composer and copyright, that is common courtesy, but also insufficient to demonstrate that you have the necessary license. You could, in theory, be sued if you were to distribute photocopies of the sheet music (even for free), but there is typically little chance of anyone doing that to you for a single instance. If you take it to a retail print shop and have them run off a hundred copies, you would both be guilty of a federal felony, since they are taking money for willful infringement. Bottom line: yes, it's illegal in most cases; however, you are unlikely to be sued for one or two copies.

- Q: Can plastic sheets be recycled into new plastic products?

- Yes, plastic sheets can be recycled into new plastic products. The recycling process involves collecting the plastic sheets, cleaning and shredding them into small pieces, melting them down, and then reforming the molten plastic into new products.

- Q: I had a plastic bag in which bed sheets came and it disintegrated in my closet. How could this happen?

- It must have been a compostable bag. They make them to only last so long and then they disintegrate.

- Q: Can plastic sheets be used for partitions?

- Yes, plastic sheets can be used for partitions. They are lightweight, durable, and easy to install, making them a cost-effective option for creating temporary or permanent partitions in various settings such as offices, hospitals, or homes. Plastic sheets also offer the advantage of being transparent or translucent, allowing for natural light to pass through while maintaining privacy.

Send your message to us

2024 New Factory Manufacture PVC Foam Board Machine for Plastic Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords