2024 5052 5083 6061 7075 Aluminum Batten Strips Aluminum Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: renovations...

(3).Advertisement: display , signboards, fascia, shop fronts...

3. Feature of Aluminum

Aluminum alloys have been the primary material of choice for structural components of aircraft since about 1930. Although polymer matrix composites are being used extensively in high-performance military aircraft and are being specified for some applications in modern commercial aircraft, aluminum alloys are the overwhelming choice for the fuselage, wing, and supporting structure of commercial airliners

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

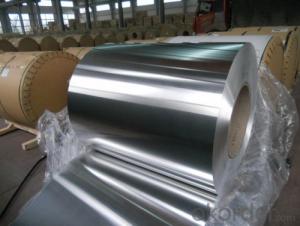

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Describe the process of manufacturing aluminum strips.

- <p>Aluminum strips are made through a series of processes starting with the production of aluminum ingots. The ingots are heated and then rolled into thin sheets in a hot rolling mill. This process reduces the thickness of the aluminum and elongates it into a strip. The hot-rolled strips are then cooled and may undergo further cold rolling to achieve the desired thickness and hardness. After rolling, the strips may be annealed to improve their ductility and strength. The final step includes cutting the strips to the required length and packaging them for distribution. This process ensures that aluminum strips have the desired properties for various applications such as construction, automotive, and aerospace industries.</p>

- Q: Can the high frequency of aluminum band replace the high frequency of professional high-power loudspeaker box?

- Can not be replaced, professional speakers generally use the horn loudspeaker, the sound directivity and speaker sensitivity are high, with a sound tweeter transient, clear, but the power and sensitivity of traditional voice Miss horn loudspeaker

- Q: Is it possible to use aluminum strips as a material for indoor flooring or wall cladding?

- <p>Yes, aluminum strips can be used for both indoor flooring and wall cladding. They are lightweight, durable, and resistant to corrosion, making them suitable for various interior applications. Aluminum strips are also easy to install and maintain, and they can provide a modern, sleek look to any space. However, it's important to consider the specific requirements of your project, such as load-bearing capacity, thermal insulation, and aesthetic preferences, to ensure that aluminum strips are the right choice for your needs.</p>

- Q: Why should single core cable be armored with aluminium tape?

- The current flowing in the three-phase three core cable in magnetic field, they produce offset each other, only a few of the unbalanced current magnetic field generated by an electric current in the metal will be released, so the heating field is not too serious, can use the steel jacket.

- Q: What benefits can be gained from using aluminum strips as a siding material for buildings?

- <p>Aluminum strips for siding offer several advantages, including durability, low maintenance, and resistance to rust and corrosion. They are lightweight, which makes installation easier and quicker. Aluminum siding is also energy-efficient, as it can help to insulate a building, reducing energy costs. Additionally, it is recyclable and environmentally friendly, contributing to sustainability efforts. The material is available in a wide range of colors and styles, allowing for great flexibility in design. It is also resistant to harsh weather conditions, making it a popular choice for various climates.</p>

- Q: Is it possible to install aluminum siding on a historic building without compromising its aesthetic or structural integrity?

- <p>Using aluminum siding on a historic building can be done without damaging its appearance or structure if done correctly. It's crucial to ensure that the siding is installed in a manner that respects the building's historical integrity. This often means using siding that closely matches the original materials in terms of color and texture, and installing it in a way that doesn't alter the building's structural elements. Consulting with historic preservation experts and adhering to local preservation guidelines is essential to maintain the building's historic character while providing the benefits of modern siding materials.</p>

- Q: This question asks for the distinctions between a roof made from an aluminum strip and a general metal roof. It seeks to understand the specific characteristics that differentiate these two types of roofing materials.

- <p>An aluminum strip roof is a specific type of metal roof, characterized by its lightweight and flexibility. Aluminum strips are often used for their corrosion resistance and durability. They are typically interlocking and can be easily bent to fit various roof shapes. In contrast, a metal roof is a broader category that includes various types of metal materials, such as steel, zinc, or copper, used for roofing. Metal roofs can be made from solid sheets, tiles, or strips, and they offer different levels of weight, durability, and maintenance requirements. While both are long-lasting and resistant to weather, the choice between an aluminum strip roof and other metal roofs often comes down to specific project needs, cost, and aesthetic preferences.</p>

- Q: What types of aluminum strips are known for their durability?

- <p>Yes, there are several types of aluminum strips known for their durability. One of the most durable types is 7075 aluminum, which is an alloy that offers high strength and is commonly used in aerospace applications. Another durable option is 6061 aluminum, which is a heat-treatable alloy with good mechanical properties and is often used in construction and transportation. Additionally, 3003 aluminum is known for its corrosion resistance and is used in applications where durability against weathering is important. The durability of aluminum strips can also be enhanced through various surface treatments and coatings.</p>

- Q: This question asks if aluminum strips can be used as a substitute for conventional roofing materials in regions with cold weather conditions.

- <p>Yes, aluminum strips can be used to replace traditional roofing materials in cold climates. Aluminum is a lightweight, durable, and corrosion-resistant material that can withstand harsh weather conditions, including snow and ice. It is also low maintenance and has a long lifespan. However, it's important to consider thermal insulation properties, as aluminum is a poor insulator. Proper insulation and underlayment should be used to prevent heat loss and protect the structure from moisture. Additionally, ensure that the installation meets local building codes and consult with a professional to address any specific concerns related to cold climates.</p>

- Q: This question asks for methods to identify if the roof material is aluminum strips.

- <p>To determine if your roof is made of aluminum strips, you can look for the following characteristics: 1) The roof has a shiny, metallic appearance, which is typical of aluminum. 2) The strips are lightweight and flexible, making them easy to handle. 3) They are often interlocking, which is a common feature of aluminum strip roofing. 4) Check for any manufacturer's markings or labels that might indicate the material. If you're unsure, a professional roof inspector can help confirm the material by examining the roof closely or taking a small sample for testing.</p>

Send your message to us

2024 5052 5083 6061 7075 Aluminum Batten Strips Aluminum Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords