Plastic Tubes - 2024 China PP-R Pipe Fitting for Industrial Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

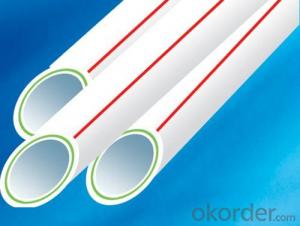

The comprehensive technical performance and economic indicator of PP-R are much better than galvanized pipe, UPVC pipe, polyethylene-aluminum compound pipe, PE-X (cross-linked polyethylene) and polybutylene pipe etc. For this reason PP-R is the leading products and widely used for feed-water piping in developed countries in Europe and America.

Nowadays PPR pipes win more attention and have been used all over the whole world more widely with its excellent sanitization performance, high heat resistance, compression resistance, corrosion resistance, pliability and seismic performance which make PP-R the real environmental friendly pipe

Product Description

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

Product Show

Applications of PPR Pipe (white, gray):

1) Cold and hot water supply systems for civil and industrial constructions, e.g. in residential buildings, hospitals, hotels, school and office buildings, ship building

2) Drinking water systems and food industry pipe works

3) Central air conditioning system

4) Irrigating system for gardens and green houses

5) Public and sport facilities such as swimming pools and stadiums

6) For rainwater utilization systems.

Our Services

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. after sending, we will track the products for you once every two days, until you get the products. When you got the

goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer

the solve way for you.

- Q: Where des this charge come from? Why don't we see a charge on the fur or wool?

- whilst something is rubbed with something else what comes into play is Frictional electrical energy . there is something talked approximately as the artwork function that's the minimum potential required via the electrons on the exterior to leave it . So if Fur and rubber are rubbed in accordance to the ques rubber rod will become negatively charged for this reason fur might desire to be dropping electrons for this reason , btw utilising molecules doesnt appear as if a sturdy concept to me so , in accordance to me C is the main suitable answer .

- Q: What are the advantages of using plastic tubes?

- Plastic tubes offer several advantages, including durability, flexibility, and cost-effectiveness. They are resistant to corrosion, chemicals, and extreme temperatures, making them suitable for a wide range of applications. Additionally, plastic tubes are lightweight, making them easy to transport and install. They can be easily customized, allowing for various shapes, sizes, and colors to meet specific needs. Plastic tubes also have a long lifespan and require minimal maintenance, making them a reliable and long-lasting choice.

- Q: How do plastic tubes compare to fiberglass tubes in terms of strength?

- In terms of strength, fiberglass tubes are generally considered to be stronger than plastic tubes.

- Q: Why do all squeeze tubes have a square at the top?

- Do you mean at the portion furthest from the opening with the cap? Because the tube is filled from the end that is furthest from the opening with cap. Years ago (before flexible plastics existed) all tubes were made from a thick aluminum foil, the cap was put on it, the tube was filled from the opposite end from the cap, and the tube was sealed after filling by folding the open end over a few times and crimping it, which always produced a square end. Now adays with plastic tubing, which is sealed by melting the tube end together you could make it have pretty much any shape, but due to tradition a square end is still used, because that is what customers are used to buying.

- Q: a molten plastic flows out of a tube 8 cm long at a rate of 13 cm^3/min where the pressure differential between the two ends of the tube is 18 cm of mercury. find the viscosity of the plastic. the i.d of the tube is 1.30 mm. the density of mercury is 13.6 g/ cm^3the answer is 0.097 kg/m.s or 97 cp! help!

- Hello Cedric Mapula, let us use the expression V/t = pi P a^4 / 8 l eta Here V/t = volume flown in one sec = 13 cm^3 / 60 s = 13/60 cm^3 /s pi = 3.14 P = 18*13.6*980 a = 1.3/ 20 cm = 0.065 cm l = 8 cm eta = ? Plug these and find the required eta i.e. coefficient of viscosity of liquid Ans : 0.969 g/cm*s = 0.969*10^-3/10^-2 kg/m*s = 0.0969 kg/m*s

- Q: How do plastic tubes compare to rubber hoses in terms of flexibility?

- Plastic tubes are generally less flexible than rubber hoses.

- Q: How do plastic tubes compare to fluoropolymer tubes in terms of chemical resistance?

- Fluoropolymer tubes generally exhibit superior chemical resistance compared to plastic tubes. This is due to the unique properties of fluoropolymers, such as PTFE (polytetrafluoroethylene) or FEP (fluorinated ethylene propylene), which have excellent resistance to a wide range of chemicals, solvents, and corrosive substances. Plastic tubes, on the other hand, may vary in their chemical resistance depending on the type of plastic used. While some plastics may offer decent resistance to certain chemicals, they are generally less resistant than fluoropolymers and may be prone to degradation or reaction with certain chemical substances.

- Q: What is the difference between rigid and flexible plastic tubes?

- The main difference between rigid and flexible plastic tubes lies in their physical properties. Rigid plastic tubes are inflexible and do not easily bend or deform, offering more stability and strength. On the other hand, flexible plastic tubes can easily bend and adapt to different shapes and angles, providing greater versatility and ease of use.

- Q: What is the maximum diameter-to-length ratio for plastic tubes?

- The maximum diameter-to-length ratio for plastic tubes can vary depending on the specific type of plastic and the intended application. However, in general, the maximum diameter-to-length ratio for plastic tubes typically ranges from 1:10 to 1:20.

- Q: Are plastic tubes suitable for agricultural irrigation?

- Yes, plastic tubes are suitable for agricultural irrigation. They are lightweight, durable, and resistant to corrosion, making them ideal for transporting water in agricultural settings. Additionally, plastic tubes can be easily installed, maintained, and have the flexibility to adapt to different terrain and irrigation systems.

Send your message to us

Plastic Tubes - 2024 China PP-R Pipe Fitting for Industrial Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords