High Density Laminated PVC Board Plastic Sheets - 2024 New Product

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1. good quality

2. virgin material

3. high performance

4. excellent hardness

We can offer HDPE sheets and rods, according to your needs.

For more information, plz feel free to contact me at yancia(at)dzxjhg.com

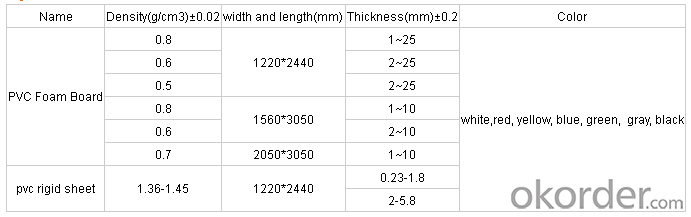

Product Specification

Regular size: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness:1-33mm

Density:0.43mm-0.9mm

Product Description

1.Weldable/Bendable - suitable for fabrication

2.UV Resistant - Black only

3.Physiologically inert - approved for food applications (Natural only)

4.Electrical insulation - it is a good insulator

5.Weatherproof - it doesn't absorb water

6.Chemical resistance - resists corrosive chemicals (e.g. Sulphuric Acid, Caustic Soda)

Technical data:

Properties | unit | Result |

Specifica Gravity | g/cm³ | 0.95 |

Max Continuous Operating Temp: | °C | 80 |

Hardness Rockwell: | - | M63 |

Dielectric Strength: | KV/mm | 45 |

Surface Resistivity: | Ohms | >1014 |

Relative Abrasion Loss by Sand Slurry: | - | 500 |

Food Grade: | FDA | Yes (Natural Only) |

Product Application

(1)Advertising: exhibition display, digital printing, silk screen printing, computer lettering, sign board, light box, etc.

(2)Construction: office and bathroom cabinets, inner and outer decorate panel, commercial decorating shelf, room separating

(3)Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layer and other industry.

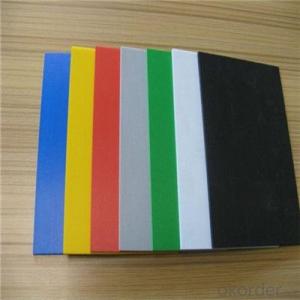

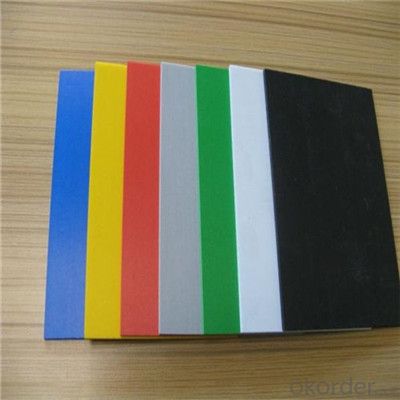

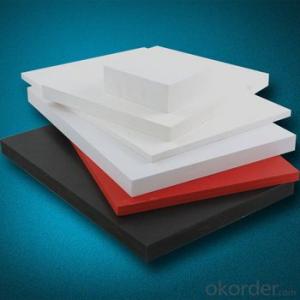

Pictures

FAQ

Q1: Are you a factory manufacturer or a trade company?

What are your product ranges? Where is your market?

A: we are manufacturer specializing in stationery and plastic packing products in highly quality

and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,

packages of cosmetic and other daily necessities, they are mainly famous ,

such as USA, AUSTRILA, CANADA,EUROPE ,MIDDLE EAST,SOUTHEAST ASIA AND SO ON.

Q2: If the products have some quality problem ,how will you deal with it?

A1: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q2: Could you provide samples?

A2: Yes, We provide free samples for customers, but customer shall bear the freight charges or negotiate about this.

- Q: You find these types of lighting in schools, hospitals, offices, industrial areas. But what are the plastic sheets called?

- Panels yahmar

- Q: Are plastic sheets resistant to warping from humidity?

- Plastic sheets can vary in their resistance to warping from humidity. Some types of plastic, like polycarbonate or acrylic, have good resistance to warping and can withstand high humidity levels without deforming. However, it is important to note that prolonged exposure to extreme humidity or moisture can still cause some plastic sheets to warp over time. Therefore, it is advisable to choose the appropriate type of plastic sheet and consider environmental conditions when using them.

- Q: Why should the aluminum-plastic composite board retain the polyethylene plastic not less than 0.3mm thick when cutting the inner aluminum sheet and polyethylene plastic?

- Accurately stated, aluminum plate in the opening processing, not cutting, but behind the groove.

- Q: I want to use plastic pallet (made from polypropylene material) to store drum's (bout 200 kg each), it was so slippy. So i want to put a rubber grip on it.. i wonder how to stick a rubber grip at plastic pallet? pls help me.. thanks all.

- you could use a glue called gorilla glue. It is the strongest type of glue i know... The only thing is that you can not get it on your hands because if you get it on your hands and you touch something, you are going to be stuck and will have to wait for the glue to wear off and because the glue is waterproof, you should watch out. If you are interested, check this site out. You can Gorilla glue at Wal-Mart(it most likely there)

- Q: I just bought a pickup truck, and it has this large 4'x8' plastic sheet in the back. Its about an inch thick, and weighs a LOT. It has nothing to do with a bed liner or anything. It seems to be extremely durable, from being in the back of a work truck for over 10 years its just got some scratches. Does anyone know what it could be used for? I want to try and sell it, but I have absolutely no idea what its purpose is, so I dont know how to even list it! One of my friends suggested it may be used for flooring or something, but i have no idea. I could see it being cut up and used for bench tops or something of that sort, but again, no clue. Any ideas?

- It probably was used as a bed liner, the rest of us just use a sheet of plywood and this guy had access to the plastic sheeting, so used that instead

- Q: Why does Dexter not get caught? He seems to make a lot of mistakes. e.g All the plastic sheets he uses?

- Because Miami Homicide are really, really stupid.

- Q: Can plastic sheets be used for skylight domes?

- Yes, plastic sheets can be used for skylight domes. Plastic materials, such as polycarbonate, acrylic, or fiberglass, are commonly used for skylight domes due to their durability, lightweight nature, and ability to transmit natural light. These plastic sheets are often designed to be impact-resistant, UV-resistant, and provide insulation properties, making them suitable for skylight applications.

- Q: Thanks you guys! You're always so smart!

- It depends on whether this is a mathematics question or a real one that involves actually doing the work. If it's math, then you would cut the piece into 96 1/8 strips and then chop them into 16 3/4 pieces or vice versa, it doesn't matter which you do first. 96 x 16 = 1536. There are 8 strips 1/8 wide in each inch and there are 12 inches in your sheet so 8 x 12 = 96. 12 divided by 3/4 = 16. 96 x 16 = 1536. If this is a real activity, then it depends on the type of plastic you're using and whether you can cut it with a knife or paper cutter because if it's plexiglass you have to use a saw of some sort and you can lose up to 1/8 for each cut due to the teeth of the saw blade. Therefore you would have approximately half as many finished pieces, and you would probably lose half of those because they'd fly all over the shop. Plexiglas is also prone to static electricity and would attract all the dust in the environment and be kind of a beast to do without special acrylic blades. Thin sheets of film could be done with scissors or a paper cutter.

- Q: Can plastic sheets be used for skylight covers?

- Yes, plastic sheets can be used as skylight covers.

- Q: How can I remove the glass glue from the plastic?

- Nail polish remover. The usage is similar to alcohol acetone. The effect is also good. Washing water does not require quality, good or general, as long as you can wash off all nail polish.

Send your message to us

High Density Laminated PVC Board Plastic Sheets - 2024 New Product

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords