125 Mono Solar Cell 5 Inch Efficiency 2.85W-3.5W

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Quick Details | |||||

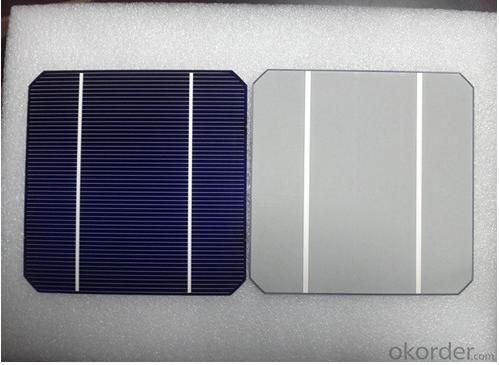

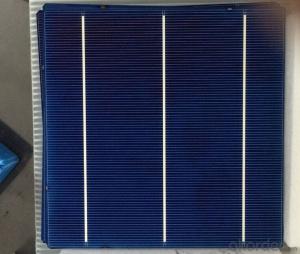

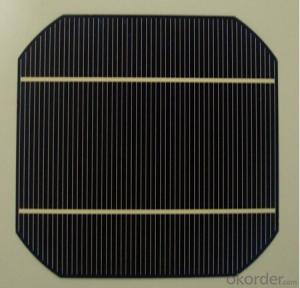

| Material: | Monocrystalline Silicon | Bus Bar: | 2 | Grade: | A |

| Size: | 125*125mm | Max. Power: | 2.85w-3.5W | Efficiency: | 18.6-22.87 |

| Packaging & Delivery | |

| Packaging Detail: | Typical package for one box is 1,000 cells.These cells are sealed in paper boards every 100 PCS.Gross weight per unit box shall be around 16kg |

5'' High Efficiency Mono Solar Cell 125*125 mm

Our Advantage

Reason:

We enjoy exclusive channel to get solar cells at more competitive price from Sunpower,Neo solar,Motech,Gintechetc.

We signed long term purchase contract with Taiwan tier 1 solar cell manufacturers,including but not limited to Neo solar,Motech,Gintech,AUO,then we can purchase unsorted solar cells in bulk from them and sort these unsorted solar cells into same efficiency,same pattern,same color by our own QA team. We call them Grade A-.

Quality :

These sorted solar cells have same electrical performance with Taiwan Grade A solar cells,only difference is the negligible superficial defect.

We can guarantee that they are better than grade A solar cells from tier 1 solar cell manufacturers in China mainland.

Description

1.Mechanical Specification:

Product Mono-crystalline silicon solar cell

Dimension 125 mm x 125 mm ± 0.5 mm

Thickness 200 μm ± 30 μm

Front 1.4mm bus bar(silver),blue anti-reflecting coating(silicon nitride)

Back 2.0 mm wide soldering pads(silver) Back surface field (aluminum)

2.Electrical Properties

| Efficiency (%) Pmpp (W) Vmpp(V) lmpp (A) Voc(V) lsc(A) |

| 19.40-19.50 3.01 0.54 5.61 0.64 5.93 |

| 19.30-19.40 2.99 0.54 5.58 0.64 5.92 |

| 19.20-19.30 2.97 0.54 5.55 0.64 5.92 |

| 19.10-19.20 2.96 0.53 5.54 0.64 5.90 |

| 19.00-19.10 2.94 0.53 5.51 0.64 5.89 |

| 18.90-19.00 2.93 0.53 5.50 0.63 5.87 |

| 18.80-18.90 2.91 0.53 5.47 0.63 5.86 |

| 18.70-18.80 2.90 0.53 5.46 0.63 5.85 |

| 18.60-18.70 2.88 0.53 5.43 0.63 5.84 |

| 18.40-18.60 2.85 0.53 5.40 0.63 |

Packaging & Shipping

1. Payment term: T/T in advance (W/U for sample order)

2. Lead time: It depends on your quantity. Usually we will send sample within 1-3 working days.

3. Shipping will be made via EMS, DHL, TNT, UPS, Air, Sea etc. shipment

4. Others: If you have special specifications and requirements, we will do different offer as you required.

Our Services

Pre sale:

1.Our sales representative and engineer work together to answer your questions and offer solution for free

2.We choose the best product for you to make sure it worth its real value

3.We design the best solution with good perfomance for you,manwhile save every cent of your money.

After sale:

We can change broken solar cell for you or compensate for your lost.

Solar cells are electronic semiconductor components, by means of which sunlight can be converted into electric energy. The semiconductor body can consist, for instance, of silicon or a III-V compound such as gallium arsenide and is provided on its front side facing the radiation source with a p-n junction of large area by means of diffusion.

A method for manufacturing solar cells comprising growing semiconductor whiskers on a substrate, comprising:

(a) Providing a substrate which favors growth or germination of whiskers;

(b) Depositing a plurality of localized areas of an agent in which the semiconductor material is soluble;

(c) Growing whiskers of said semiconductor material by means of the Vapor Liquid Solid (VLS) method at said areas;

(d) Doping the whiskers with one of a p or n doping material; and

(e) Subsequently thereto doping the surface region of said whiskers up to a depth which approximately corresponds to the diffusion length of the charge carriers pairs with the other of a P or n doping material.

Estimating the manufacturing cost of purely organic solar cells

we estimate the manufacturing cost of purely organic solar cells. We find a very large range since the technology is still very young. We estimate that the manufacturing cost for purely organic solar cells will range between $50 and $140/m2. Under the assumption of 5% efficiency, this leads to a module cost of between $1.00 and $2.83/Wp. Under the assumption of a 5-year lifetime, this leads to a levelized cost of electricity (LEC) of between 49¢ and 85¢/kWh. In order to achieve a more competitive COE of about 7¢/kWh, we would need to increase efficiency to 15% and lifetime to between 15–20 years.

Manufacturing Solar Cells

First, silicon raw material is melted and re-cast to remove impurities. The cast silicon is then stabilized in its multicrystalline form. These castings, called "ingots," are then cut into blocks. Next, the ingots are sliced into wafers.( Depending on the type of silicon used, p-type or n-type silicon wafers may be produced). After layering the p-type or n-type wafers, the material is capable of generating electricity from sunlight. Electrodes are attached to the wafers to conduct the flow of electricity. This is called a photovoltaic cell, or "solar cell."

- Q: How long does it take for solar cells to pay for themselves?

- The payback period for solar cells can vary widely depending on factors such as the initial cost of the system, local energy prices, available incentives, and the amount of electricity generated. On average, it can take anywhere between 5 to 15 years for solar cells to pay for themselves through energy savings and potential government incentives.

- Q: What is the difference between polysilicon and monocrystalline silicon photovoltaic cells?

- Monocrystalline silicon is made of polycrystalline silicon by a single crystal furnace, but also useful for the preparation of monocrystalline silicon melting. Polysilicon is the direct raw material for the production of monocrystalline silicon, which is the basic material of electronic information for semiconductor devices such as contemporary artificial intelligence, automatic control, information processing, photoelectric conversion and so on. Known as the "cornerstone of the microelectronics building."

- Q: Can solar cells be used in recreational vehicles?

- Yes, solar cells can be used in recreational vehicles. They are a popular and effective solution for powering various systems in RVs including lighting, appliances, and electronics. Solar panels can be mounted on the roof of an RV to harness sunlight and convert it into electricity, providing a reliable and sustainable source of power while on the road or during camping trips. Additionally, solar cells offer the advantage of being environmentally friendly and reducing reliance on traditional energy sources.

- Q: Can solar cells be used for water desalination?

- Yes, solar cells can be used for water desalination. Solar energy can be harnessed by solar cells to power the desalination process, typically through either photovoltaic or solar thermal technologies. This enables the conversion of seawater or brackish water into fresh water by removing the salt and other impurities, making solar-powered desalination a sustainable and eco-friendly solution for addressing water scarcity in coastal regions.

- Q: How do solar cells convert sunlight into electricity?

- Solar cells convert sunlight into electricity through a process called the photovoltaic effect. The cells are made of semiconductor materials, usually silicon, that absorb photons from the sunlight. These absorbed photons excite the electrons in the material, allowing them to break free from their atomic bonds. The freed electrons then flow through the cell's material, creating an electric current. This current can be harnessed and used as electricity to power various devices and systems.

- Q: How do solar cells handle hail or other severe weather conditions?

- Solar cells are designed to withstand severe weather conditions including hail. They are made with durable materials such as tempered glass that can handle impact from hailstones. Additionally, solar panels are tested and rated for their ability to withstand extreme weather events, ensuring their resilience in harsh conditions.

- Q: Can anybody tell me the power supply of the home solar cell?

- l can give you an example as following: 40W * 4H=160Wh=0.16 degree power In accordance with the summer sunny weather one day 5 standard sun, consider 70% system efficiency 160 / 5 / 70%=45.7W, so 50 Watt Solar cell is enough.

- Q: How do solar cells handle electromagnetic radiation?

- Solar cells are designed to handle electromagnetic radiation by converting it into usable electrical energy. The materials within the solar cells absorb photons from the sunlight, which in turn generates an electric current. This process effectively harnesses the energy from the electromagnetic radiation and allows solar cells to produce clean and renewable electricity.

- Q: Why are the poly Solar cell specifications is different from each other, they seem to have the different size of 125mm, 156mm, 152mm, is the 152mm's battery technology is higher than the other?

- Most of the popular products in the market is 125mm or 156mm, because the 152mm is not really practically useful in the market.

- Q: What is the effect of wind on solar cell performance?

- The effect of wind on solar cell performance can be both positive and negative. On one hand, wind can help cool the solar cells, preventing overheating and improving their overall efficiency. Additionally, wind can help clean the surface of the solar panels, removing dust and debris that may obstruct sunlight and reduce energy production. On the other hand, strong winds can create vibrations and mechanical stress on the solar panels, potentially damaging their structure or causing misalignment. Therefore, while some wind is beneficial for solar cell performance, excessive or turbulent wind conditions may have a detrimental impact.

Send your message to us

125 Mono Solar Cell 5 Inch Efficiency 2.85W-3.5W

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords