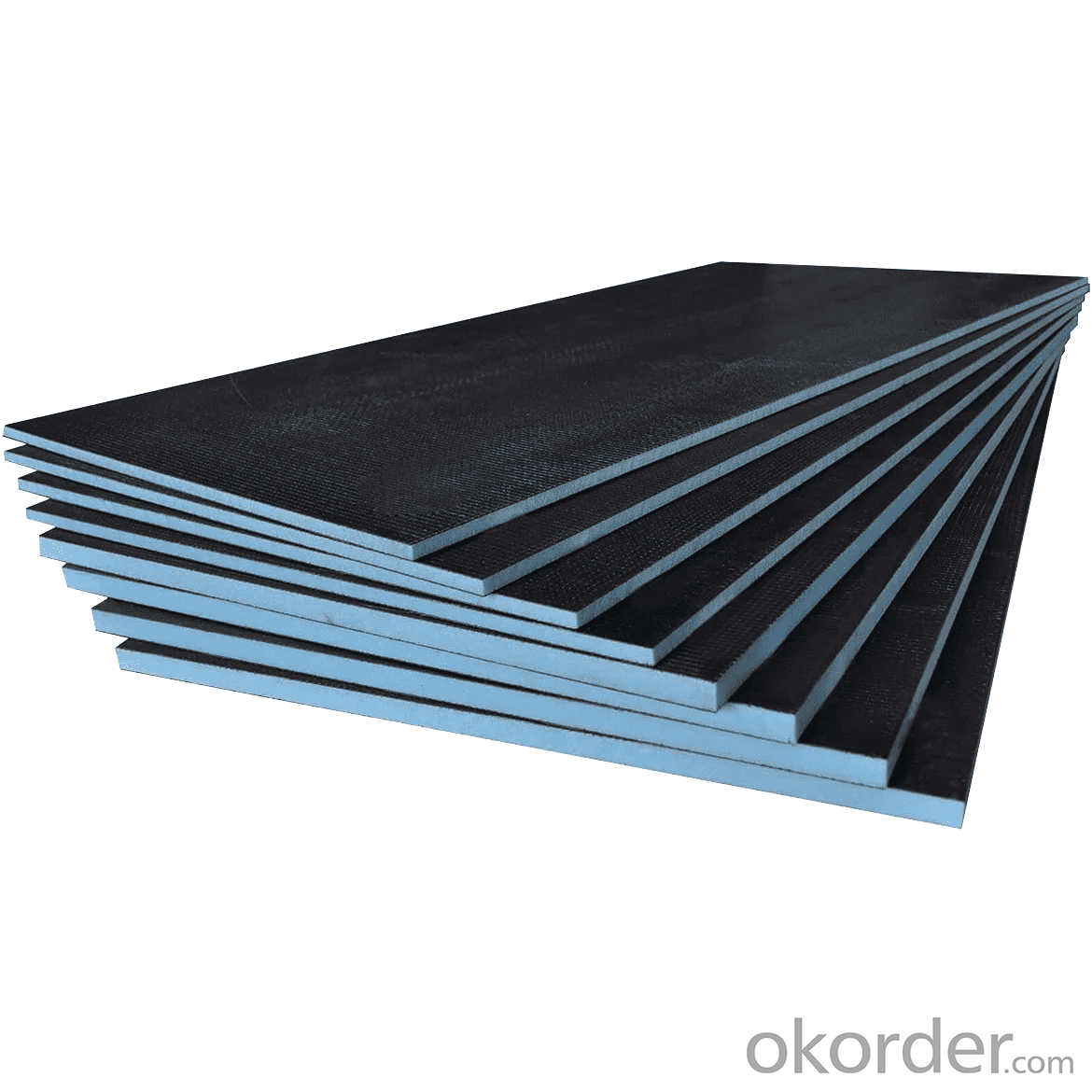

1200x600x20mm Water-Resistant Construction Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

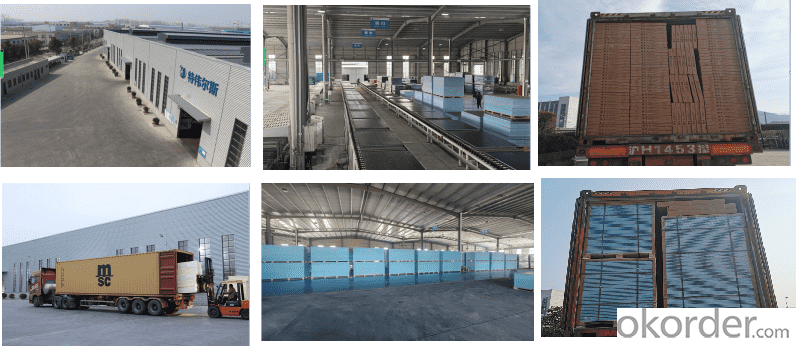

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wetroom 12mm Tile Backer Board For Walls and Floors 1200mm x 600mm (10 Pack)

XPS Tile Backer Board

When it comes to effective insulation solutions for your construction or tiling projects, XPS insulation boards are a reliable choice. we offer a wide range of XPS insulation boards, also known as XPS foam boards or simply XPS boards. These boards are designed to provide excellent thermal insulation, moisture resistance, and durability, making them ideal for various applications.

XPS insulation boards are constructed from extruded polystyrene foam, known for its high compressive strength and low thermal conductivity. This combination of properties makes XPS boards highly efficient in reducing heat transfer and improving energy efficiency in buildings. Whether you're insulating walls, floors, or roofs, XPS insulation boards offer a reliable solution.

Our selection of XPS foam boards includes various thicknesses and sizes to accommodate different project requirements. From smaller DIY projects to large-scale commercial installations, we have the right XPS insulation board to suit your needs. These boards are easy to handle and cut, allowing for precise fitting and installation.

we pride ourselves on providing high-quality products and exceptional customer service. Our knowledgeable staff are available to assist you in selecting the right XPS insulation board for your specific project. We also offer fast shipping and hassle-free returns to ensure your complete satisfaction with your purchase.

Whether you're a professional contractor or a DIY enthusiast, our XPS boards will help you create a comfortable and energy-efficient environment.

Performance parameters

Technical | Assessed to | Rating |

XPS Foam Density | DIN 53420 | 32±0.02kg/m³ |

Compressive strenghth (kPa) | EN 826 | ≥450 |

Thermal conductivity(W/m・K) | EN 12167 | ≤0.030 ≤0.034 |

Dimesional stability % (70±2℃) 48h | GB/T8811-2008 | ≤1.5 |

Flexural Strength (Mpa) | ASTM C203 | ≥2.8 |

Water Absorption(96hrs immersion) | ISO 2896 | ≤1.5 |

Water Vapour Permeability | ASTM E-96 | ≤3.0 |

Flammability | EN13501 | B2 |

Tensile strength perpendicular to the board | GB/T30595-2024 | ≥0.2Mpa |

Advantages

Advantages

1. impact resistant and rigid.

2. Waterproof and temperature resistant & Vapour retardant.

3. Thermally insulating.

4. Quick and easy to install.

5. Lightweight, easy to handle and transport.

6. Easy to cut (with a utility knife).

7. Applied to use on any kind of background substrate.

8. Applied to freestanding p

artition walls,shelves, coverings and similar surfaces.

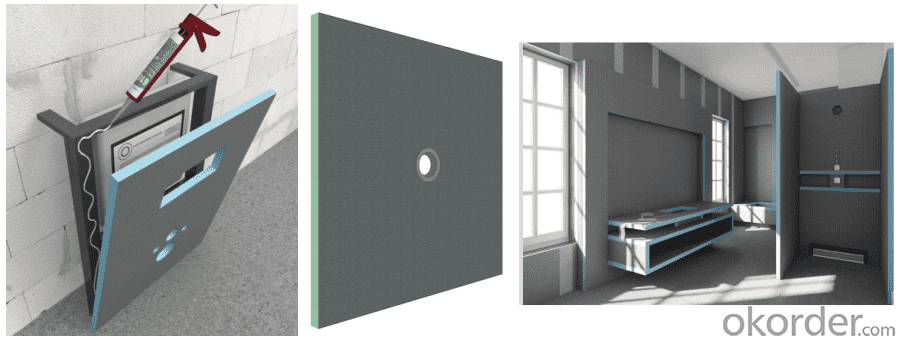

Applications

Bathrooms and Showers: Perfect for walls and floors in showers and bathrooms where water exposure is constant.

Kitchens: Ideal for kitchen backsplashes and countertops, providing a moisture-resistant base.

Wet Rooms: Suitable for creating fully waterproof wet rooms with tiled surfaces.

Exterior Spaces: Can be used in outdoor areas where moisture and temperature changes are a concern.

- Q: Slope roof drains do not need to be waterproof

- When installing a waterproof board, when the width of a waterproof board is not enough, to be placed side by side, it should be noted that the gap between the board and the plate will provide potential space for root growth.

- Q: How to do waterproof bathroom, construction process is what

- 3, shop protective layer. In order to prevent the subsequent construction damage to the waterproof layer, the need to cover the surface of the waterproof coating protective layer. Protective layer to completely cover the waterproof layer, no missing, with the grass-roots combination of solid, no cracks, no bubbles, no shedding phenomenon.

- Q: What is the car waterproof sticker material?

- Engraving process car sticks A. knife engraving process: refers to the computer will be vector graphics input knife machine, the knife will be cut into a preset film shape, and then by hand will be different colors together Finished, and finally in the finished product posted on the surface of a layer of transparent transfer film, after the stickers to remove the stickers; due to knife car paste production process is complex, high cost of materials, currently only suitable for individual car and Che Youhui team Small customization

- Q: What material waterproofing can be mixed with cement sand

- Waterproof layer used in the cement label of not less than 32.5MPa, the thickness of cement mortar should be 2-3cm, the surface clean and solid without cracks; mortar leveling layer of cement should not be less than 32.5MPa, leveling layer to smooth compaction, finished product maintenance is not low In 5 days.

- Q: Can Henkel have water against him?

- Add a small amount of water is possible because the premise of waterproofing should also be wet before the grassroots

- Q: Nanning building waterproof material market where

- This depends on what you need packaging materials, and if it is some packaging rope or paper or process raw materials and other different materials to find a different place, generally sold outside the packaging is more like Nanning near the train station Or the trading market,

- Q: Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Need to waterproof the external walls, there are several programs. First, directly in the existing external walls of the main surface of the water treatment, the use of technology and materials due to different external finishes and different;

- Q: FRP finished brush on what can be waterproof do not fade

- On the surface of the gel coat it is, a lot of gel coat points, the specific performance of what you want, you can communicate with the supplier

- Q: Why should the use of high pressure perfusion waterproof plugging method

- High pressure grouting construction features: 1, a high degree of finished product 2, simple operation; reduce the construction time 3, the construction from the weather; 4, non-toxic pollution;

- Q: How can the toilet waterproof works fail?

- Use 755 new waterproof material can be painted three times. There is also a new type of waterproof material is water-like brush is also three times, you can go to the building materials market to see, you know.

Send your message to us

1200x600x20mm Water-Resistant Construction Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products