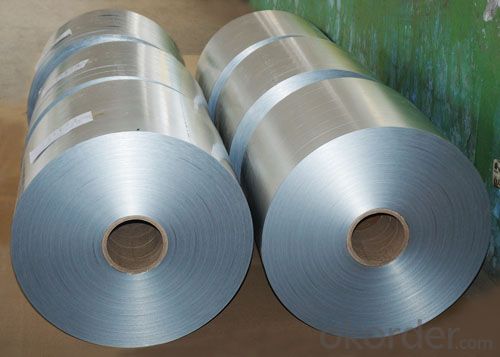

APV 25 Aluminum Coil 1100 1200 O H14 H24 Mill Finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1100 1200 O H14 H24 Mill Finish Aluminium Coil

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q: What are the common sizes and thicknesses of aluminum coils?

- Common sizes and thicknesses of aluminum coils vary depending on the specific application and industry. However, there are some standard sizes and thicknesses that are commonly used across various industries. In terms of size, aluminum coils typically range from around 12 inches to 72 inches in width. This range allows for flexibility in accommodating different production processes and equipment. The length of the coils can vary as well, but it is often in the range of 1000 to 6000 feet. As for thickness, aluminum coils come in various gauges, which are commonly measured in inches or millimeters. The most commonly used thicknesses for aluminum coils are between 0.019 inches (0.48 mm) and 0.125 inches (3.18 mm). These thicknesses are suitable for a wide range of applications, including roofing, construction, automotive, and manufacturing. It is important to note that these are general guidelines, and the specific size and thickness requirements may vary depending on the intended use of the aluminum coils. Additionally, custom sizes and thicknesses can also be manufactured to meet specific project requirements.

- Q: What’s the production standard of aluminum coil?

- GB/T3880-2006 mechanical standard GB/T3190-1996 chemical standard

- Q: What are the advantages of using aluminum coils over other materials?

- Some advantages of using aluminum coils over other materials include its lightweight nature, excellent thermal conductivity, corrosion resistance, and ease of fabrication. Additionally, aluminum coils offer good electrical conductivity, making them suitable for various applications in industries like automotive, construction, and aerospace.

- Q: What are the factors that affect the cost of aluminum coils?

- The cost of aluminum coils can be influenced by various factors. Firstly, the price of aluminum itself can fluctuate based on global supply and demand, as well as market conditions. These fluctuations directly impact the cost of aluminum coils. Secondly, the manufacturing process involved in producing aluminum coils plays a significant role in determining their cost. Different techniques, such as casting, rolling, and annealing, each have their own associated costs. The complexity and efficiency of the manufacturing process can directly affect the final price of the coils. Additionally, the size, thickness, and specifications of the coils can also impact their cost. Larger coils or those with specific dimensions may require extra raw materials, processing time, or specialized equipment, leading to higher costs. The type of surface finish applied to the coils is another factor that influences their price. Coils with higher-quality finishes, such as brushed or coated surfaces, require additional processing and materials, making them more expensive. Furthermore, the quantity and order volume of aluminum coils can affect their cost. Larger order quantities often result in economies of scale and lower unit costs. Conversely, smaller orders or customized specifications may incur additional setup costs or higher per-unit prices. The level of competition in the aluminum coil industry also plays a significant role in pricing. Increased competition among manufacturers can lead to more competitive prices as companies vie for customers. Conversely, limited suppliers or unique product offerings can drive prices higher due to reduced competition. Transportation and logistics costs are another factor to consider. The distance, mode of transportation, and fuel prices impact shipping costs, which can be passed on to customers. It is important to note that these factors are not exhaustive and may vary depending on specific circumstances and market dynamics. Additionally, external factors like taxes, tariffs, and government regulations can also influence the cost of aluminum coils.

- Q: How do aluminum coils perform in applications where high strength is required?

- Aluminum coils perform well in applications where high strength is required due to their excellent strength-to-weight ratio. This allows them to provide necessary structural integrity while reducing the overall weight of the application. Additionally, aluminum coils can be further strengthened through various alloying and heat treatment methods, making them suitable for demanding and high-stress environments.

- Q: What are the standard dimensions for aluminum coils?

- The dimensions of aluminum coils can vary depending on their intended use and the industry they are being used in. However, there are generally accepted standard dimensions for aluminum coils. In terms of width, aluminum coils can range from 4 inches (10 cm) to 60 inches (152 cm). The exact width will depend on factors such as the purpose of the coils, the manufacturing process, and the customer's specifications. When it comes to thickness, aluminum coils are available in various gauges or millimeters. Common thicknesses can range from 0.018 inches (0.46 mm) to 0.25 inches (6.35 mm) or even thicker in certain applications. The length of aluminum coils can also vary based on customer requirements or industry standards. Coils can be supplied in standard lengths, such as 1000 feet (304.8 meters) or 2000 feet (609.6 meters), or they can be custom-cut to a specific length. It is important to note that these dimensions are not fixed and can be customized to suit the needs of a particular project. Different industries, like construction, automotive, and aerospace, may have their own specific size requirements for aluminum coils. Therefore, it is recommended to consult with an aluminum coil manufacturer or supplier to determine the most appropriate dimensions for a specific application or project.

- Q: Are aluminum coils compatible with different joining methods?

- Yes, aluminum coils are compatible with different joining methods. Some common joining methods for aluminum coils include welding, soldering, brazing, and mechanical fastening. The choice of joining method depends on the specific application and requirements.

- Q: Can aluminum coils be used in high-altitude environments?

- Yes, aluminum coils can be used in high-altitude environments. Aluminum is known for its lightweight and corrosion-resistant properties, which make it suitable for various applications, including those in high-altitude environments. Additionally, aluminum has a high strength-to-weight ratio, allowing it to withstand the challenges posed by high altitudes.

- Q: What specific tools are necessary for handling and working with aluminum coils?

- <p>When working with aluminum coils, there are several special tools that may be required. These include cutting tools designed for metal, such as metal shears or a bandsaw with a metal cutting blade, to cut the coils without damaging the material. A coil car or lifting equipment is necessary for safely moving and positioning heavy coils. Additionally, a coil leveler may be needed to straighten and flatten the coils for processing. Safety equipment such as gloves and goggles is also essential to protect against sharp edges and flying debris. It's important to use tools that are suitable for the specific aluminum alloy and thickness to ensure efficient and safe handling.</p>

- Q: Are aluminum coils suitable for electrical transformer applications?

- Yes, aluminum coils are appropriate for use in electrical transformer applications. Aluminum coils possess several advantages over traditional copper coils when utilized in transformers. To begin with, aluminum is a lightweight metal, making it easier to handle and transport. This is particularly advantageous for large transformers where reducing weight is desired. The lightweight nature of aluminum coils also facilitates easier installation and maintenance. Secondly, aluminum exhibits excellent electrical conductivity, albeit not as conductive as copper. However, aluminum coils can compensate for lower conductivity by employing larger wire sizes or increasing the number of turns. This ensures that the transformer operates efficiently and effectively. Moreover, aluminum has a higher thermal conductivity compared to copper. Consequently, aluminum coils can dissipate heat more efficiently, which is crucial for the proper functioning and longevity of transformers. This increased heat dissipation aids in reducing the transformer's operating temperature, thereby enhancing its overall performance. Furthermore, aluminum serves as a cost-effective alternative to copper. Generally, aluminum is less expensive than copper, making it a more economical option for transformer manufacturers. This cost advantage can be particularly significant in large-scale transformer production. However, it is important to note that there are certain considerations to be mindful of when utilizing aluminum coils in transformer applications. Aluminum coils are more susceptible to oxidation and necessitate proper insulation to prevent corrosion. Additionally, aluminum coils may exhibit slightly higher electrical losses compared to copper coils, although advancements in design and manufacturing techniques have mitigated this concern. In conclusion, aluminum coils are indeed suitable for use in electrical transformer applications. They offer benefits such as lightweight construction, excellent electrical conductivity, superior thermal conductivity, and cost-effectiveness. However, it is crucial to implement proper insulation and preventive measures to address any potential challenges associated with aluminum coils, ensuring optimal performance and durability of the transformers.

Send your message to us

APV 25 Aluminum Coil 1100 1200 O H14 H24 Mill Finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords