1.8mm 2mm Black Diamond PVC Conveyor Belt for Treadmill Walking Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.8mm 2mm Black Diamond PVC Conveyor Belt for Treadmill Walking Belt

Description of Treadmill Conveyor Belt

Our company introduced and use the most advanced production technology which are extrusion method,lamination method and calendering method to produce light duty PVC, PU and PE conveyor belts, compared with the other factories using the traditional coating method, our belts have more advantages:1. high flatness, the height flatness is within ±0.05mm;2. high density;3. high tensile strength;4.reliable splice, it can reach the same service life as the original;5.good performance of anti-abrasion and chemical&oil resistance.

We offer a variety of different treadmill belt types to meet diverse technical and commercial needs. The range includes traditional treadmill belts as well as maintenance-free types for commercial and institutional treadmill units.

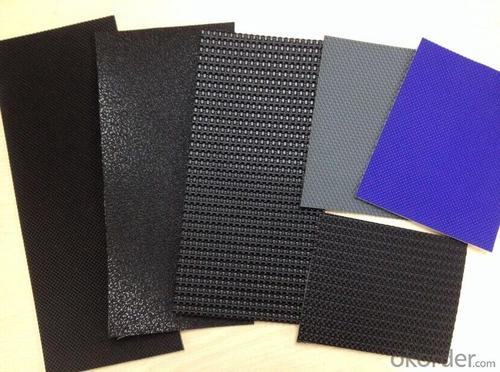

Patterns:

Flat, Grass , Golf, Diamond, Matte surface finish, Small round particles and etc.

Features of Treadmill Conveyor Belt

1. Non-Conductive

2. Anti-Static

3. Resistant to fats, chemicals, oil fat and abrasion

4. Various surfaces with high, medium and low coefficient friction

Applications of Treadmill Conveyor Belt

Widely used in the Conveyance and production assembly lines in the areas

of airports, postal automation, parcel handling, treadmills, packaging/wrapping, cigarettes,

tobacco,leather, foodstuffs, drinks, medicine,chemical,tyre ,electronics, pharmaceutical,

printing,papermaking, wood, stone/marble, entertainment industry and fishery industry etc.

Pictures of PVC Treadmill Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the

samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS,

DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you

can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: Classification of other rubber sheets of wear-resistant rubber plates

- RIT ceramic abrasion resistant rubber sheetRubber surface with uniform ceramic block, can drive the roller and the conveyor belt between the grip of excellence, usually used in all kinds of extreme working conditions, such as muddy, wet, and high wear roller under the environment of rubber processing.

- Q: Can PVC blend with rubber?

- Ding Qing rubber is highly polar and can mix with any proportion of PVC. Other polar rubbers, such as chlorinated polyethylene and chlorinated polyethylene, can be mixed.

- Q: Is mixed silicone rubber dangerous?

- With excellent thermal stability, high and low temperature resistance, can -60 to +250 DEG C under the condition of long-term work, ozone resistance, weatherability and good electrical properties, corona resistance, electric arc, electric spark is extremely strong, with chemical stability, weathering resistance, radiation resistance, physical inertia and good air permeability.

- Q: What kind of rubber coated aluminum alloy (metal) better

- White Silicone, or at cyanide rubber, you have to brush the surface of metal binder, general is muruk we do, rubber products, these things often encounter

- Q: How to solve the exhaust problem in rubber vulcanization process

- Rubber: the word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process. The finished product is material with elasticity, insulation, waterproof and air

- Q: What kinds of vulcanized rubber do you have?

- According to the properties and uses of rubber: in addition to natural rubber, synthetic rubber can be divided into general synthetic rubber, semi general synthetic rubber, special synthetic rubber and special synthetic rubber.

- Q: Rubber products are not allowed to touch oil products, but why can rubber gloves be contacted daily? What's the point?

- Contact every day is not every day inside the bubble, the contact time is short, the impact on rubber is very small.Raw rubber rubber products are: natural rubber, isoprene rubber, nitrile rubber, EPDM rubber, polybutadiene rubber, styrene butadiene rubber, polyurethane rubber, chloroprene rubber, silica gel etc.

- Q: What kind of material does the shockproof rubber cushion usually choose? What's the hardness?

- The air tightness of butyl rubber is the best of all the rubber, is its biggest advantage, it is mainly used for tyres, although there are shock absorbing function, but dynamic flex is not ideal.

- Q: What kind of rubber does TPE belong to?

- Thermoplastic elastomer TPE (Thermoplastic, Elastomer) is a kind of material with high elasticity, high strength, high resilience, and has the characteristics of injection molding. Nontoxic security, wide range of hardness, with excellent color, soft touch, weather resistance, fatigue resistance and temperature resistance, excellent processing performance, without curing, can reduce the cost of recycling, can be two times of injection molding, and PP, PE, PC, PS, ABS and other base materials the adhesive, can also be a separate molding.

- Q: Is there any poison in the processing and testing of rubber products? What about the salary?

- Rubber products processing and testing of this work has low toxicity, pay attention to ventilation, strengthen physical exercise, no problem!! The salary is average, basically between 2500--3500!

Send your message to us

1.8mm 2mm Black Diamond PVC Conveyor Belt for Treadmill Walking Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords