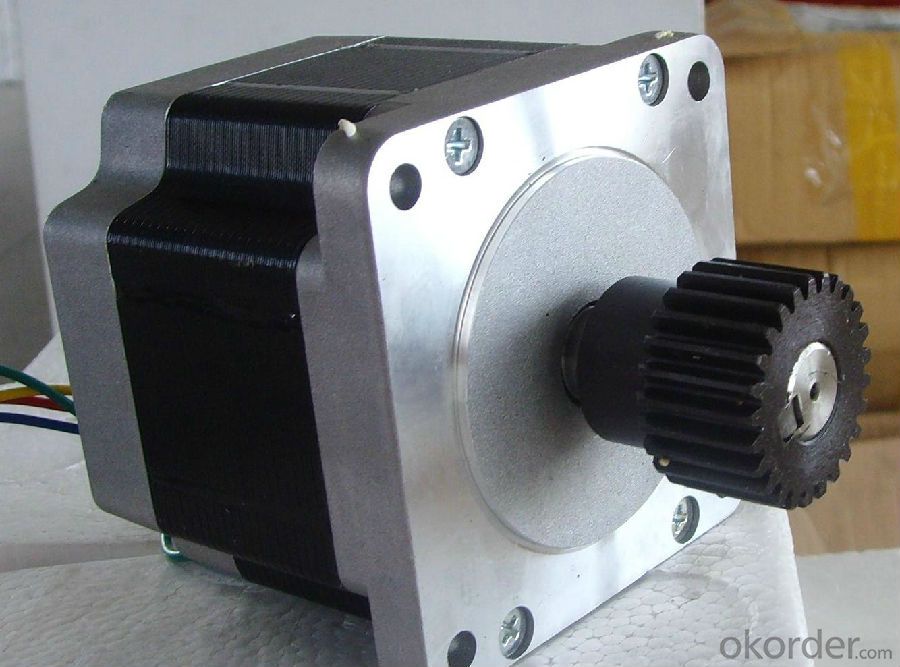

1.8degree NEMA34 2phase 1.7mh Inductance Micror Motor

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 2500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.8degree NEMA34 2phase 1.7mh Inductance Micror Motor

Product Details

Basic Info.

Model NO.:86HS67-5904

Number of Stator:Two-Phase

Excitation Mode:HB-Hybrid

Type:Electromechanical

Step Angel:1.8 Degree

Motor Length:67mm

Current:5.9A

Holding Torque:3.4 N.M

Export Markets:Global

Additional Info.

Trademark:JK

Packing:Export Carton

Standard:CE/ROHS/ISO9001

Origin:Changzhou, China

HS Code:8501109990

Production Capacity:200, 000PCS/Month

Product Description

1.8degree NEMA34 2phase 1.7mH inductance micro sstepper motor

Item Specifications:

Step Angle 1.8degree

Temperature Rise 80. C Max.

Ambient Temperature -20. C~+50. C

Insulation Resistance 100MΩ Min., 500VDC

Dielectric Strength 820VAC for 1s 3mA

Shaft Radial Play 0.02Max. (450 g-load)

Shaft Axial Play 0.08Max. (450 g-load)

Max. Radial force 220N (20mm from the flange)

Max. Axial force 60N

1. NEMA8 Hybrid Stepper Motor

2. Model Number: JK86HS67 - 5904

3. Phase: 2 Phase

4. Lead Wire (No. ): 4wires

5. Structure: Hybrid

6. Step Angle: 1.8 degree

7. Motor Height: 67mm

8. Current: 5.9A

9. Resistance: 0.28Ω

10. Inductance: 1.7 mH

11. Motor Weight: 1.7 KG

12. Holding Torque: 3.4 N. M

13. Speed: Low / High speed

14. Certification: CE, RoHS, ISO9001

15. Shape: Square

16. Applications: Use for robots stepper motor, electronic automatic equipment stepping motor, medical instrument stepping motor, advertisementing instrument stepper motor, lighting& audio equipment stepper motor, printer stepper motor, textile machinery stepper motor. CNC router stepper motor.

Description:

1.8 degree Size 86mm Hybrid stepper motor. 3D Printer stepper motor

86mm size stepper motor, NEMA34 stepping motor,

Small stepping motors, 2 phase 86mm stepper motor, Stepper motor 86mm size

Hybird Stepper Motors

1) CE and RoHS approved

2) We can develop customer design version

Applications:

Use for robots stepper motor, electronic automatic equipment stepping motor, medical instrument stepping motor, advertisementing instrument stepper motor, lighting& audio equipment stepper motor, printer stepper motor, textile machinery stepper motor.

CNC router stepper motor.

About our manufacturer:

We are a professional manufacturer for Stepper motor, Stepper driver, BLDC motor and DC motor. We can supply OEM service.

Our products all with CE and RoHS.

Welcome you visit our company Changzhou Jingkong Motor&Electric Appliance Co., Ltd

Depending on advanced technology and knight service, we establish a good and diligent team and keep nice business relationship with a large amount of worthy clients in global market. We are prepared to provide the best products to clients at competitive price.

High quality.

Competitive price,

Good Packing,

Fast Delivery.

Timely after-sales service.

If you need more information. Please contact with us, our contact information:

Changzhou Jingkong Motor&Electric Appliance Co., Ltd

Contact Person: Ms Jane

More Quantity. More discount! ! !

| Model No. | Step Angle | Motor Length | Current /Phase | Resistance /Phase | Inductance /Phase | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | N.m | No. | Kg.cm | g.cm² | Kg | |

| JK86HS67-5904 | 1.8 | 67 | 5.9 | 0.28 | 1.7 | 3.4 | 4 | 0.8 | 1000 | 1.7 |

| JK86HS67-2808 | 1.8 | 67 | 2.8 | 1.4 | 3.9 | 3.4 | 8 | 0.8 | 1000 | 1.7 |

| JK86HS78-5504 | 1.8 | 78 | 5.5 | 0.46 | 4 | 4.6 | 4 | 1.2 | 1400 | 2.3 |

| JK86HS78-4208 | 1.8 | 78 | 4.2 | 0.75 | 3.4 | 4.6 | 8 | 1.2 | 1400 | 2.3 |

| JK86HS115-6004 | 1.8 | 115 | 6.0 | 0.6 | 6.5 | 8.7 | 4 | 2.4 | 2700 | 3.8 |

| JK86HS115-4208 | 1.8 | 115 | 4.2 | 0.9 | 6 | 8.7 | 8 | 2.4 | 2700 | 3.8 |

| JK86HS155-6204 | 1.8 | 155 | 6.2 | 0.75 | 9 | 12.2 | 4 | 3.6 | 4000 | 5.4 |

| JK86HS155-4208 | 1.8 | 155 | 4.2 | 1.25 | 8 | 12.2 | 8 | 3.6 | 4000 | 5.4 |

- Q: How to reduce the S to the actual step motor control!

- The acceleration of the S + deceleration is a trapezoid, and the area of the trapezoid is the difference between the initial velocity (acceleration zero) and the target velocity (acceleration zero). S-shaped so to planning goal and deceleration must first know the starting speed difference (area), and know the most acceleration duration (that is, the top of the ladder duration) and S curve part time duration (namely the trapezoidal left, right), thus the shape of a trapezoid is fixed, can be calculated by calculation and acceleration (jerk).

- Q: I just want to know, how many pulses does it take to get into the motor?

- Two phase stepper motor, the step (understandable subdivided into 1), one revolution of the 200 pulse interval Angle is 1.8 °, 360 ° / 200), half step interval Angle is 0.9 °. The corresponding three-phase step motor, the whole step 300 pulse a circle. Subdivision steps behind can intuitive see corresponding segment, the step is to give much pulse went a circle, such as 2 behind segment is 400 steps, which means 400 pulse motor turns a circle. The number of steps in the following is a description of the segmentation, which is aimed at reducing the low frequency vibration and noise of the stepping motor. It's a little messy, I hope you can help.

- Q: What's the difference between a step-down motor and a dc decelerator? I want to control it with a single chip, and I don't know what the difference is. What is the mode of control?

- Stepper motor and dc motor in the electrical machinery is a completely different type of motor, dc motor as long as plus appropriate voltage will turn, and turn laps is difficult to precisely control; The stepper motor works according to the beat, which can rotate a tiny Angle (such as 0.1 degree). Step gear motor and dc gear motor are based on their respective motor increased the reduction gear (gear), can put the droop down, and the role of the speed reducer is similar. There have difference control manner, control of stepping motor is similar to digital circuit, needs a beat (similar to the digital tube display, single chip cycle parallel output certain values, according to certain rhythm.) Commonly used small, can use ULN2003 stepper motor drive, and a much higher working current of dc motor, general small dc motors with a dedicated driver chip driver L298N, general output PWM wave to control by single chip microcomputer control.

- Q: How do you adjust your step to 90 degrees?

- If fixed 90 ° running, is to choose the best type switch control drive such as EZD552, just give a start signal, the machine will automatically run 90 °.

- Q: The relationship between the step motor drive and the controller and the encoder

- A step motor is an actuator that has the ability to control the Angle of rotation, the direction, or the number of turns. The actuator is a power amplification system that accepts the number of pulses and the rotation direction of the step motor. The controller accepts the encoding instruction, the man-machine dialogue, and the change of the instruction to the central component of the drive. This is where the coder detects the Angle of rotation of the motor, the direction, and feedback to a detector element in the controller.

- Q: Type: 103-845-02, 3VDC 6.7 A, 6 lines "red, yellow, blue, black, white, green", not knowing how to connect?

- Six line is generally in the two groups, with multimeter pens and pick up one of the first line, and then, in turn, points the other lines, all of is another group, the remaining two are with you through this is a group of a group of the inside of the three lines, one of which is a center tap, use pens and repeated the test three lines, the largest is the coil resistance between the two ends of the tap, the rest is the center tap. This will determine the definition of all the lines!

- Q: Do you need a speed reducer to step into the motor? What is the effect of a speed reducer?

- As with your car, though the throttle is able to control the speed of the car, it must be switched lower.

- Q: How little force does a phase 6 step into an electric machine? How do you turn the torque?

- I don't know if you take the lead of the motor to the launch grade of the triode or the collector. But that's ok. No matter the pole, the motor is not strong enough to be sure that the current running through the motor is too small to increase the current. The output torque of the machine will increase significantly. Note that the added current should not exceed the rated current of the motor.

- Q: The difference between stepping motor, steering machine, servo motor?

- Steering gear (electronic steering machine) : the main component of the steering machine is servo motor. It contains servo motor control circuit + reduction gear group. Oh, yes, the servo motor has no reduction gear. The steering gear has a reduction gear. If it is a limit steering machine, determine the steering Angle by the potentiometer below the output shaft. Steering signal control is a kind of pulse width modulation (PWM) signal, which is easily generated by microcontrollers.

- Q: The difference between the servo motor and the step motor

- I take it very seriously, to answer the question of science, to be sure, not to mislead the questioner, and the answers of these answers are misleading Performance comparison of stepper motor and ac servo motor The step motor is a discrete motion device that is intrinsically linked to modern digital control technology. In the domestic digital control system, the application of stepping motor is very broad. With the advent of full digital communication servo system, ac servo motor is increasingly applied to digital control system. In order to adjust to the development trend of digital control, most of the motor control system is used as an actuator motor. Although the two are controlled in similar ways (pulse train and direction), there are significant differences in performance and application situations. Now compare the performance of the two.

Send your message to us

1.8degree NEMA34 2phase 1.7mh Inductance Micror Motor

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 2500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches