1/8 Aluminum Strips - Quality China Prepainted/Printed Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

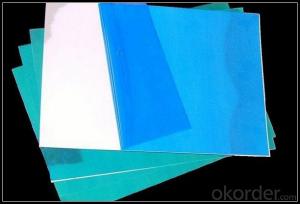

Our mill can produce all kinds of color pe pvdc painting aluminum coils ,which is used for build roof sheets:

1.Usually materials is:Alloy A3003H24 A3003H26 A3003H12 A3004H24 A3003h26

With thickness:0.6mm 0.7mm 0.8mm 0.9mm1.0mm

With width:22-1600mm

Color:according to customer

Coating:PE coated 25-28 Micro

Plastic film:0.05 or 0.06 mm film covered on the surface,could with customers' logo

Package:With inner-diameter 405mm or 505mm ,durable package for transport on sea,or as per required

.

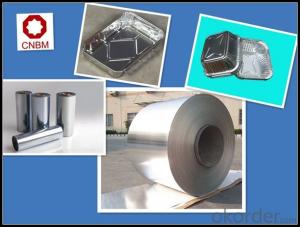

2.specification: color pe pvdc painting aluminum coils

| Product | prepainted aluminum coil/printed aluminum coil |

| Thickness | 0.2mm-4.0mm |

| Popular Thickness | 0.25mm/0.3mm/0.4mm/0.45mm/0.5mm/0.6mm/0.9mm/1.0mm/2.0mm... |

| Width | under 1700mm |

| Popular size of sheet | 1000*2000,1200*2400,1219*2438,1220*2440 1000*3000,1250*3000,1500*3000 etc. |

| weight | about 2000kg |

Material | 1050,1060,1100,3003,3004,3105,5052,5005, 5754,5083,6061,6063 etc |

| Temper | O,H12,H14,H16,H18,H24,H26, H32,H34,H111,H112,T3,T5,T6 etc |

| Inner Diameter | 505mm |

| Color | white, gray ,gold ,blue,red,etc.(as per customer’s requirement) |

| Total coating thickness | PVDF coating: more than 25micron PE coating : more than 18 micron |

| Packing | Export standard wooden pallets (as per requirements) |

| Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

| Minimum Order Quantity | 5 tons per size |

| Delivery time | 20-30days after receiving L/C or deposit |

| Loading Port | Qingdao China (any port in China ) |

| Application | Lighting, printing, packing, decorative, electronics surface, ect. |

| Remark | Specific requirement of alloy grade,temper or specification can be discussed at your request |

3.Features: color pe pvdc painting aluminum coils

1) Super peeling strength

2) Excellent surface flatness and smoothness

3) Superior weather, corrosion, pollutant resistance

4) Even coating, various colors

5) Fireproof, excellent heat and sound insulation

6) Superior impact resistance

7) Lightweight and easy to process

8) Easy to maintain

4.Application: painted polyester aluminium foil/pe coating aluminium foil

1) Building exterior curtain walls

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels

7) Industrial materials, materials for vehicles and boats

features

- Q: What specific tools or equipment are necessary to install aluminum strips?

- <p>To install aluminum strips, you generally need a few basic tools. A measuring tape is essential for accurate placement. A utility knife or a metal cutting tool is necessary for cutting the strips to the correct length. A level is crucial to ensure the strips are straight. A rubber mallet or a hammer can be used to secure the strips in place. Adhesive, such as construction adhesive or double-sided tape, is often required to attach the strips. Safety equipment like gloves and safety goggles should be worn to protect against sharp edges and debris.</p>

- Q: Explain how aluminum strips can impact the waterproofing process and their role in construction.

- <p>Aluminum strips play a crucial role in waterproofing by serving as a barrier against water penetration. They are often used in construction to seal joints and seams where water could potentially infiltrate. These strips are durable, corrosion-resistant, and flexible, making them ideal for maintaining a watertight seal even under fluctuating temperatures and structural movements. They can be used in conjunction with other waterproofing materials such as sealants and membranes to create a robust defense against water damage. By preventing water from entering buildings or structures, aluminum strips help to protect against moisture-related issues like mold, structural decay, and deterioration, thereby enhancing the longevity and integrity of the construction.</p>

- Q: This question asks about the uses of aluminum strips within the construction industry.

- <p>Aluminum strips are widely used in construction due to their strength, durability, and resistance to corrosion. They are commonly used in the manufacturing of window and door frames, as they are lightweight and provide excellent thermal insulation. Aluminum strips are also used in the construction of scaffolding, roofing, and cladding systems due to their high strength-to-weight ratio and ease of installation. Additionally, they are employed in electrical wiring as conduits and in the framing of structural components due to their non-magnetic and non-sparking properties, making them safe for use around electrical equipment.</p>

- Q: Is it possible to use aluminum strips to construct a solar reflector system for residential or commercial purposes?

- <p>Yes, you can use aluminum strips to create a solar reflector system for your home or business. Aluminum is a reflective material and can be shaped into strips to reflect sunlight. These strips can be arranged in a way to direct sunlight towards solar panels or into specific areas to reduce the need for artificial lighting and heating. However, for optimal efficiency, you should consider the angle of reflection, the positioning of the strips relative to the sun's path, and the overall design of the system. Consulting with a professional in solar technology can help ensure that your solar reflector system is effective and safe.</p>

- Q: Is it possible to install aluminum siding on a historic building without compromising its aesthetic or structural integrity?

- <p>Using aluminum siding on a historic building can be done without damaging its appearance or structure if done correctly. It's crucial to ensure that the siding is installed in a manner that respects the building's historical integrity. This often means using siding that closely matches the original materials in terms of color and texture, and installing it in a way that doesn't alter the building's structural elements. Consulting with historic preservation experts and adhering to local preservation guidelines is essential to maintain the building's historic character while providing the benefits of modern siding materials.</p>

- Q: Is it possible to construct awnings or canopies using aluminum strips?

- <p>Yes, aluminum strips can be used to make awnings or canopies. They are lightweight, durable, and resistant to corrosion, making them suitable for outdoor applications. Aluminum's strength and flexibility allow it to be bent and shaped easily, which is ideal for creating the curved or angled structures often seen in awnings and canopies. However, it's important to ensure that the aluminum is of sufficient gauge to support the weight and withstand environmental stresses. Additionally, proper sealing and treatment are necessary to prevent water damage and maintain the longevity of the structure.</p>

- Q: What are the cost differences between aluminum and aluminum strips?

- <p>Aluminum and aluminum strips are both made from the same base material, but their costs can differ due to several factors. Aluminum strips are typically more expensive than bulk aluminum due to the additional processing and manufacturing steps involved in creating them. These steps include rolling, cutting, and sometimes surface treatments, which add to the cost. Additionally, aluminum strips often have tighter tolerances and specific dimensions, which can also increase their price. However, the exact cost difference can vary based on factors such as market prices for aluminum, the complexity of the strip's specifications, and the quantity purchased.</p>

- Q: What is the chemical composition represented by the formula for aluminum strips?

- <p>The chemical formula for aluminum strips is simply Al. Aluminum is a chemical element with the symbol Al and atomic number 13. It is a silvery-white, soft, nonmagnetic, and ductile metal in group 13 of the periodic table. Aluminum strips are made of this single element and do not contain any other elements or compounds.</p>

- Q: This question asks for the distinction between two types of aluminum products: strips and profiles.

- <p>Aluminum strips are flat, thin pieces of aluminum, often used for applications requiring flexibility or where a thin cross-section is needed. They are typically used in packaging, electrical components, and construction. Aluminum profiles, on the other hand, are extruded shapes with a more complex cross-section, such as bars, tubes, angles, or channels. These profiles are used in structural applications, furniture, and various mechanical components where strength and specific shapes are required. The main difference lies in their form and application; strips are for flat, thin uses, while profiles are for more robust, structural uses.</p>

- Q: What are the drawbacks or negative aspects associated with the use of aluminum strips?

- <p>The disadvantages of using aluminum strips include their relatively low strength compared to some other metals, making them less suitable for heavy-duty applications. They can also be prone to corrosion, especially in humid environments, which can reduce their lifespan. Additionally, aluminum strips may not be as rigid as other materials, leading to potential issues with structural integrity. Lastly, while aluminum is recyclable, the recycling process can be energy-intensive, and the environmental impact of its production, including greenhouse gas emissions, should be considered.</p>

Send your message to us

1/8 Aluminum Strips - Quality China Prepainted/Printed Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords