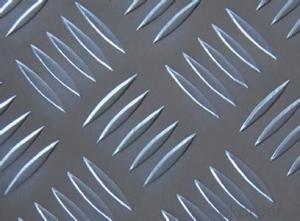

Stainless Checkered Plate

Stainless Checkered Plate Related Searches

Thickness Of Checkered Plate Stainless Checkered Plate Insulation Plate Cheap Checkered Plate Astm A786 Checkered Plate Diamond Checkered Plate Ss Checkered Plate A786 Checkered PlateHot Searches

Lasani Wood Sheet Price Aluminium Checkered Plate Price 4Mm Mdf Sheet 1220X2440Mm Price Aluminium Scaffold Planks Sale Buy Sheet Plastic Aluminium Walkway Mesh Prices 9Mm Mdf Sheet Prices Tinplate Sheet Suppliers Checkered Plate Standard Sizes Checkered Plate Suppliers Aluminium Checkered Plate Price Aluminium Walkway Mesh Prices Checkered Plate Standard Sizes Checkered Plate Suppliers Aluminium Checkered Plate Price Checkered Plate Standard Sizes Checkered Plate SuppliersStainless Checkered Plate Supplier & Manufacturer from China

Okorder.com is a professional Stainless Checkered Plate supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Stainless Checkered Plate firm in China.Hot Products

FAQ

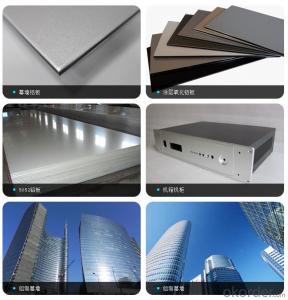

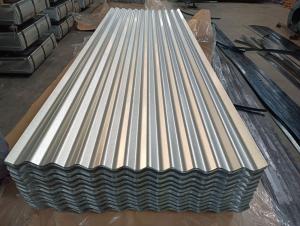

- Yes, steel sheets can be used in architectural applications. Steel is a versatile material that offers strength, durability, and design flexibility, making it suitable for various architectural purposes such as roofing, cladding, structural framing, and decorative elements. Steel sheets can be shaped, formed, and customized to meet specific architectural requirements, making them a popular choice in modern construction projects.

- Yes, steel sheets can be painted after installation. The paint can adhere to the surface of the steel sheets, providing protection against corrosion and enhancing their appearance.

- The maximum load-bearing capacity of steel sheets depends on various factors such as the thickness, grade, and type of steel, as well as the specific application and support structure. Generally, steel sheets have high load-bearing capacities ranging from a few thousand pounds to several hundred thousand pounds per square inch, making them suitable for a wide range of structural and industrial applications.

- How do I print the steel plate?

- It's not print. It was corrosion first. It's laser engraving. Now it's 20 watts above the laser to carve the metal

- What is a water stop steel plate?

- The main application areas of water stop steel plate are tunnel, subway, dyke, culvert, water conservancy and hydropower project, construction joint, basement of high-rise building, underground parking lot, etc..

- Yes, steel sheets can definitely be used in architectural or decorative applications. Steel is a versatile and durable material that offers numerous benefits for both structural and aesthetic purposes. In architectural applications, steel sheets can be used for roofing, wall cladding, and structural framing, providing strength, stability, and resistance to harsh weather conditions. Additionally, steel sheets can be fabricated into various shapes, sizes, and finishes, allowing architects and designers to create unique and visually appealing structures. In decorative applications, steel sheets can be used for interior and exterior design elements such as decorative panels, screens, railings, and sculptures. The ability to customize steel sheets with various patterns, textures, and colors makes them a popular choice for enhancing the visual appeal of buildings and spaces. Overall, steel sheets are a versatile material that can be utilized in a wide range of architectural and decorative applications, offering both functionality and aesthetics.

- Indeed, magnetic applications can make use of steel sheets. However, it should be noted that not all steel types possess magnetic properties. Steel can be divided into two primary categories: ferromagnetic and non-ferromagnetic. Ferromagnetic steel comprises iron, nickel, and cobalt, which are materials capable of being magnetized. Conversely, non-ferromagnetic steel lacks these materials and is not magnetic. Ferromagnetic steel sheets find widespread application in magnetic uses such as transformers, motors, generators, and magnetic shielding. These sheets are preferred due to their ability to efficiently conduct and amplify magnetic fields. On the other hand, non-ferromagnetic steel sheets, while not magnetic themselves, can still be employed in magnetic applications as structural components or as part of a magnetic system where the magnetic field requires control or manipulation. When selecting steel sheets for magnetic applications, careful consideration must be given to the specific magnetic properties required for the intended use, and the appropriate type of steel should be chosen accordingly.

- When handling steel sheets, there are several safety considerations to keep in mind. Firstly, it is important to wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. Secondly, steel sheets can be heavy and cumbersome, so it is crucial to use proper lifting techniques and equipment to avoid strains or muscle injuries. Additionally, sharp edges or corners on steel sheets can pose a risk of cuts or punctures, so caution should be exercised when handling them. Lastly, steel sheets can be slippery when wet or oily, so it is essential to maintain a clean and dry working area to prevent slips and falls. Overall, awareness, caution, and adherence to safety protocols are key when handling steel sheets to ensure the well-being of individuals involved.