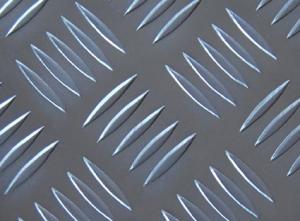

Polishing Aluminum Checker Plate

Polishing Aluminum Checker Plate Related Searches

Led Light Bulbs For Ceiling Fixtures Led Lamps For Ceiling 42 In Ceiling Fan With Light Aluminum Coil Stock For Gutters Aluminum Foil For The Grill Hole Saw For Aluminum Plate Aluminum Tread Plate For Trailer Bow Plate For Aluminum Boat Aluminum Foil For Grow Room Aluminum Foil For Joint PainHot Searches

Stock Price For Aluminum Aluminum Coil Stock For Sale Aluminum Gutter Coil For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For Sale Aluminum Bar Stock For Sale Aluminum Round Stock For Sale Aluminum Diamond Plate For Sale Aluminum Scaffolding For Sale Craigslist 6061 Aluminum Plate For Sale Aluminum Dock Plate For Sale 7075 Aluminum Plate For Sale Aluminum Tread Plate For Sale Aluminum Checker Plate For Sale Aluminum Plate For Sale Near Me Plate Aluminum For Sale Aluminum Plate For Sale Aluminum Square Stock For Sale Aluminum Flat Stock For Sale Billet Aluminum Stock For SalePolishing Aluminum Checker Plate Supplier & Manufacturer from China

Okorder.com is a professional Polishing Aluminum Checker Plate supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Polishing Aluminum Checker Plate firm in China.Hot Products

FAQ

- Yes, aluminum sheet can be used for electrical grounding applications. Aluminum is a highly conductive material, making it suitable for use in grounding systems. It is often used in various electrical applications due to its low resistance and excellent electrical conductivity. Aluminum sheet can effectively carry electrical current and safely dissipate it into the ground, ensuring the protection of electrical systems and preventing electrical hazards. Additionally, aluminum's lightweight and corrosion-resistant properties make it a preferred choice for grounding applications in various industries, including construction, automotive, and aerospace.

- Indeed, aluminum sheet serves as a suitable option for decorative uses. With its adaptability, aluminum can be effortlessly molded, trimmed, and fashioned into an assortment of patterns, rendering it an excellent choice for embellishing ventures. Whether utilized to fashion decorative paneling, sculptures, signage, furnishings, or numerous other ornamental components, aluminum proves itself indispensable. Furthermore, aluminum can be anodized or painted in an extensive array of hues, enabling additional personalization and accentuating its visual allure. Additionally, its lightweight composition and corrosion resistance render it a pragmatic selection for both indoor and outdoor decorative endeavors.

- When working with aluminum sheets, some important safety precautions to consider include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to protect against cuts, eye injuries, and inhalation of aluminum dust. It is crucial to work in a well-ventilated area or use local exhaust ventilation to minimize exposure to dust and fumes. Additionally, ensuring that the work area is clean and free of clutter can help prevent slips, trips, and falls. Finally, it is essential to handle aluminum sheets with care to avoid sharp edges and to prevent heavy sheets from falling or causing injury.

- Yes, aluminum sheets are generally resistant to impact. Aluminum is a lightweight metal that has high strength and toughness, making it capable of withstanding impact forces. It has excellent energy absorption properties, which means it can absorb and dissipate the energy generated by an impact, minimizing damage to the sheet. Additionally, aluminum sheets can be further strengthened through various processes such as heat treatment or alloying, making them even more resistant to impact. However, the impact resistance of aluminum sheets can vary depending on the specific alloy and thickness used.

- Aluminum sheets and aluminum plates differ primarily in terms of thickness and applications. Aluminum sheets are typically thinner, ranging from 0.2mm to 6mm in thickness, whereas aluminum plates are thicker, usually starting from 6mm and going up to several inches thick. Aluminum sheets are commonly used for general purposes such as packaging, signage, and roofing due to their lightweight nature and flexibility. They are often bent, formed, and cut into various shapes and sizes to fulfill specific requirements. On the other hand, aluminum plates are typically used in applications that require higher strength and durability. With their greater thickness, they provide enhanced structural integrity and are commonly utilized in industries such as aerospace, automotive, and construction. Aluminum plates can withstand heavy loads and are often used as structural components in buildings, aircraft, and machinery. In summary, the main differences between aluminum sheets and aluminum plates lie in their thickness and the specific applications they are suited for. Sheets are thinner and more flexible, suitable for general purposes, while plates are thicker and stronger, ideal for heavy-duty applications that require structural integrity.

- Yes, aluminum sheets are suitable for automotive body panels. Aluminum is lightweight, corrosion-resistant, and strong, making it an ideal material for manufacturing car body panels. It helps improve fuel efficiency, enhances performance, and reduces overall vehicle weight, making it a popular choice among automakers.