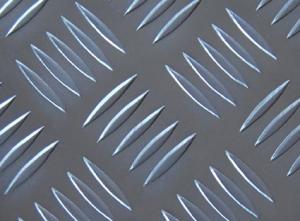

Checker Plate Aluminum Sheets

Checker Plate Aluminum Sheets Related Searches

Led Light Bulbs For Ceiling Fixtures Led Lamps For Ceiling 42 In Ceiling Fan With Light Aluminum Coil Stock For Gutters Aluminum Foil For The Grill Hole Saw For Aluminum Plate Aluminum Tread Plate For Trailer Bow Plate For Aluminum Boat Aluminum Foil For Grow Room Aluminum Foil For Joint PainHot Searches

Stock Price For Aluminum Aluminum Coil Stock For Sale Aluminum Gutter Coil For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For Sale Aluminum Bar Stock For Sale Aluminum Round Stock For Sale Aluminum Diamond Plate For Sale Aluminum Scaffolding For Sale Craigslist 6061 Aluminum Plate For Sale Aluminum Dock Plate For Sale 7075 Aluminum Plate For Sale Aluminum Tread Plate For Sale Aluminum Checker Plate For Sale Aluminum Plate For Sale Near Me Plate Aluminum For Sale Aluminum Plate For Sale Aluminum Square Stock For Sale Aluminum Flat Stock For Sale Billet Aluminum Stock For SaleChecker Plate Aluminum Sheets Supplier & Manufacturer from China

Okorder.com is a professional Checker Plate Aluminum Sheets supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Checker Plate Aluminum Sheets firm in China.Hot Products

FAQ

- heating can affect aluminium

- This is science so, if you want specific answers, you must ask specific questions. What type of aluminum are you interested in? What characteristics are important to you? What kind of factors are you talking about? You are right that heating can affect Al. In fact, heating affects, basically, everything, every material we know of and every physical and chemical process that we do and every process that happens in nature. Temperature is important in all of these. There are more than a hundred different commercial aluminum alloys and most of them are available in a variety of different tempers (heat treated conditions). The heat treatment of commercial Al alloys is a very important thing. If you want more specific information, consult your friendly neighborhood metallurgist.

- Why does the glue of the aluminium curtain wall glue bubble? At the same time, do not bubble on the side glass, what is the reason?

- Brothers, there are several kinds of bubble gum, first to check is not part of the foam glue strip plug is not good, should be smooth, playing in a plastic bubble, not to leave the air, also can't have water, air water will bubble. In addition, glue when the temperature is very important no, when hot hit. Glue master experience play a decisive role, there is a great work in absolute don't let coolie, evenness and speed are very important.

- Yes, aluminum sheets can be used for furniture manufacturing. Aluminum is a versatile material with several advantageous properties that make it suitable for furniture production. It is lightweight, durable, corrosion-resistant, and can be easily molded into various shapes and sizes. Additionally, aluminum has a sleek and modern aesthetic, making it a popular choice for contemporary furniture designs. Aluminum sheets can be used to create frames, legs, and other structural components for different types of furniture, including chairs, tables, shelves, and cabinets. The versatility and durability of aluminum make it a viable option for furniture manufacturing, especially for outdoor or industrial furniture that requires resistance to harsh weather conditions or heavy use.

- Indeed, elevator interiors can certainly be constructed using aluminum sheets. Aluminum has gained significant popularity as a material of choice for elevator interiors due to its multitude of advantageous qualities. Its lightweight nature, durability, and resistance to corrosion render it highly suitable for long-term utilization in elevator applications. With ease, aluminum sheets can be skillfully fabricated and shaped to perfectly fit the dimensions and design specifications of elevator interiors. Furthermore, aluminum can be enhanced with various types of coatings or finishes, such as anodizing or powder coating, to not only augment its aesthetic appeal but also provide additional protection. Overall, aluminum sheets represent a practical and widely utilized option for elevator interiors within the industry.

- Aluminum sheets have a wide range of common uses across various industries. They are often used in construction for roofing, siding, and structural components due to their lightweight and durable nature. In the transportation sector, aluminum sheets are utilized in the manufacturing of vehicles, including cars, airplanes, and boats, to reduce weight and improve fuel efficiency. Additionally, aluminum sheets are commonly used in packaging, electrical appliances, and signage due to their corrosion resistance and ability to be easily formed into different shapes.

- Yes, aluminum sheets are suitable for manufacturing chemical storage cabinets. Aluminum is highly resistant to corrosion, lightweight, and has good thermal conductivity, making it an ideal choice for storing chemicals safely. Additionally, aluminum is non-reactive with most chemicals, ensuring the integrity of the storage cabinets.

- Signage can greatly benefit from the use of aluminum sheets. This material is known for its versatility and numerous advantages when it comes to signage applications. With its lightweight nature, durability, and resistance to corrosion, aluminum is an excellent choice for both indoor and outdoor signage. Regardless of weather conditions, be it rain, snow, or intense UV exposure, aluminum sheets will not deteriorate or fade. Furthermore, aluminum sheets are easy to work with, providing a wide range of customization options such as embossing, engraving, and digital printing. Not only are they cost-effective, but they also have a long lifespan, ensuring that signage remains in top-notch condition for extended periods. Ultimately, due to their durability, versatility, and aesthetic appeal, aluminum sheets are a preferred choice for signage.