Seattle Solar Cells

Seattle Solar Cells Related Searches

Rec Solar Cells Free Solar Cells Better Solar Cells American Made Solar Cells Chinese Solar Cells Building Solar Cells Satellite Solar Cells Solar Energy Cells Home Depot Solar Cells Compact Solar Cells Residential Solar Cells Ibc Solar Cells Buy Solar Cells Organic Solar Cells Home Built Solar Cells Atj Solar Cells Perc Solar Cells Bio Solar Cells Hobby Solar Cells Evergreen Solar Cells Electric Solar Cells Chipped Solar Cells Photovoltaic Solar Cells Folding Solar Cells High Quality Solar Cells Solar Cell Module Alta Solar Cells 3 5 Solar Cells Creating Solar Cells Q Cells SolarSeattle Solar Cells Supplier & Manufacturer from China

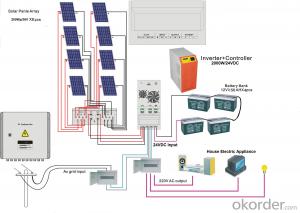

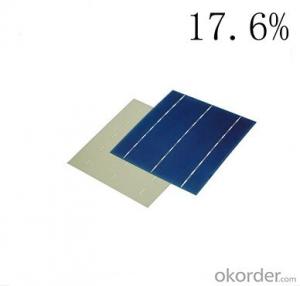

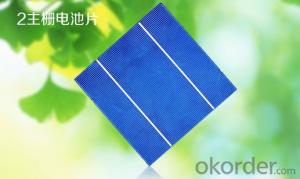

Seattle Solar Cells, known for their high-quality solar products, offers a diverse range of photovoltaic solutions that cater to various energy needs. Their products are designed to harness the power of the sun and convert it into usable electricity, making them an ideal choice for both residential and commercial applications. These solar cells are widely used in off-grid systems, grid-tied systems, and portable power solutions, providing a reliable and sustainable source of energy.Seattle Solar Cells' products are utilized in a variety of settings, from powering homes and businesses to supporting remote communication systems and electric vehicle charging stations. Their solar panels are engineered to withstand harsh weather conditions, ensuring long-lasting performance and minimal maintenance. This makes them a popular choice for those looking to reduce their carbon footprint and reliance on non-renewable energy sources.

Okorder.com is a leading wholesale supplier of Seattle Solar Cells, boasting a vast inventory that caters to the needs of various customers. With a commitment to providing top-notch products at competitive prices, Okorder.com ensures that customers have access to the latest solar technology from Seattle Solar Cells. This partnership allows for efficient distribution and availability of these cutting-edge solar solutions, making it easier for individuals and businesses to adopt clean energy practices and contribute to a greener future.

Hot Products