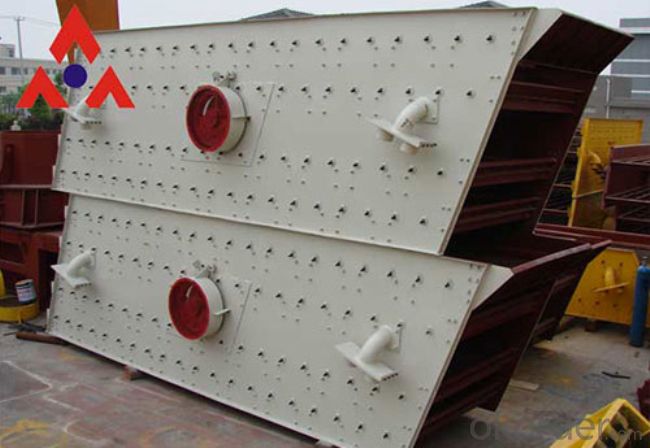

Vibrating Screen-For Stone Aggregates and Ores

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Circular Vibrating Screen

Type: Necessary Auxiliary Equipment

Input Size: 0mm--1000mm

Processed Materials: Limestone, Granite, Gabbro, Basalt, River Stone, Coal Gangue, Quartz, Diabase,Iron Ore, Copper Ore, Zinc Ore, etc.

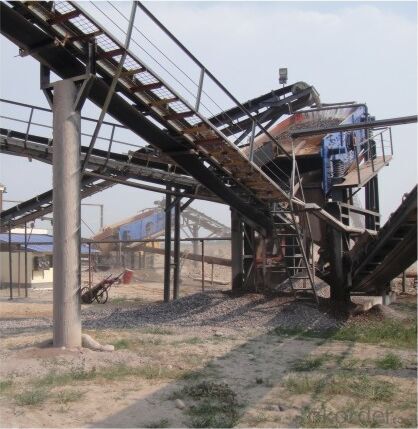

Applications: Aggregates Shaping, Mechanism sand, Bituminous Concrete, Metal Mine, Chemical, Road, Railway,Metallurgy, Construction, Highway, Water Conservancy

Capacity: 10-500TPH

The moving road of this screen is similar as a circle, so it is called Circular Vibrating Screen. Circular Vibrating Screen is of multilayer and high efficiency. The eccentric shaft vibration exciter and eccentric block helps to adjust amplitude. This kind of screen is of long screening stream line and more sieving specifications. So it is widely used for grading in the industries of quarry, building material, transportation, energy, chemical industry, etc.

1,It uses cylinder-type eccentric shaft and eccentric block to make strong vibrating force.

2,Beam is connected to the main body with bolts, has the feature of high strength.

3,The side plate of the screen box use the steel which make the boiler, the steel have high strength and strong impact resistance.

4,It adopts the structure of small amplitude, high frequency, large obliquity to make the screen with high efficiency, large handing capacity, long life span, low consumption and little noise.

5,The vibrating screen uses the motor to drive the eccentric shaft to make the screen body periodically along with the direction of vibration force. The materials make circular movement on the screen to realize sieving. Circular vibrating screen consists of vibration source, screen body, screen mesh, shock absorbing device, base frame etc. It has the features of reasonable structure and long durability.

Detail Specification:

| Model | Screen Size(mm) | Layers | Screen Mesh (mm) | Max Feed Size(mm) | Capacity (t/h) | Power (Kw) | Vibrating Frequency(r/min) | Double Swing (mm) |

| 2YK1237 | 3700*1200 | 2 | 3-80 | 100 | 10-80 | 11 | 750-950 | 5-9 |

| 3YK1237 | 3700*1200 | 3 | 3-80 | 100 | 10-80 | 11 | 750-950 | 5-9 |

| 2YK1548 | 4800*1500 | 2 | 3-80 | 100 | 30-200 | 15 | 750-950 | 5-9 |

| 3YK1548 | 4800*1500 | 3 | 3-80 | 100 | 30-200 | 15 | 750-950 | 5-9 |

| 2YK1848 | 4800*1800 | 2 | 3-80 | 100 | 50-250 | 18.5 | 750-950 | 5-9 |

| 3YK1848 | 4800*1800 | 3 | 3-80 | 100 | 50-250 | 18.5 | 750-950 | 5-9 |

| 2YK1860 | 6000*1800 | 2 | 3-80 | 100 | 60-300 | 22 | 750-950 | 5-9 |

| 3YK1860 | 6000*1800 | 3 | 3-80 | 100 | 60-300 | 22 | 750-950 | 5-9 |

| 4YK1860 | 6000-1800 | 4 | 3-80 | 100 | 60-300 | 30 | 750-950 | 5-9 |

| 2YK2160 | 6000*2100 | 2 | 3-80 | 100 | 80-400 | 22 | 700-900 | 5-9 |

| 3YK2160 | 6000*2100 | 3 | 3-80 | 100 | 80-400 | 30 | 700-900 | 5-9 |

| 4YK2160 | 6000*2100 | 4 | 3-80 | 100 | 80-400 | 30 | 700-900 | 5-9 |

| 2YK2460 | 6000*2400 | 2 | 5-80 | 100 | 100-500 | 30 | 700-900 | 5-9 |

| 3YK2460 | 6000*2400 | 3 | 5-80 | 100 | 100-500 | 37 | 700-900 | 5-9 |

| 4YK2460 | 6000*2400 | 4 | 5-80 | 100 | 100-500 | 37 | 700-900 | 5-9 |

- Q: What are the precautions for using a linear vibrating screen?

- When stopping the use of linear screen, the material must be stopped until the material of the vibrating screen and the vibrating motor are closed at the end of the screening so as to avoid waste of materials and reduce the difficulty of cleaning the straight line screen.

- Q: Vibration motor and vibration sieve, why use C3 or C4 clearance bearings and use?

- Because the greater the clearance of the bearing, the lubrication of the vibrating screen can be guaranteed, the general vibration screen bearing room wearing parts, large clearance can also increase the bearing life.

- Q: How to use the vibrating amplitude plate?

- Vibrating screen is also called vibrating screen, vibrating screen machine and sieving machine. It is a kind of sieving machine that works with reciprocating vibration of vibrator. According to the principle of vibrating screen, it can be divided into circular vibrating screen and linear vibrating screen.

- Q: How to see the number of mesh vibration sieve

- Refers to the number of orders per square inch empty eye screen, 50 holes per square inch refers to the 50, 500 is 500, the higher the number, the more holes. In addition to said screen hole, it can be said at the same time for the screen by the particle size, the higher the number, the smaller the particle size.

- Q: Is there one or two motors in the linear shaker?

- But the single vibration motor is not so good in sieving, output and precision.

- Q: What's the effect of a rattling shaker?

- Beat sieve is mainly used in laboratory or enterprise sampling inspection, the main function is the same as standard test sieve. The structure of this machine is mainly composed of stand, screen and drive mechanism. Can be widely used in the laboratory of geology, metallurgy, powder, abrasive, chemical industry, building materials, medicine, defense and other departments of screening detection, especially suitable for diamond powder, superhard materials industry production process of high strength and high grade frequency of repeated use.

- Q: How about paint vibrating screen?

- Each kind of machine has its own characteristic and the good work domain, the vibration sieve is precisely such.

- Q: What's the difference between a dewatering screen and a common vibrating screen?

- The dewatering vibrating screen adopts double motor self synchronization technology, universal eccentric block and adjustable amplitude vibrator. Through the belt shaft driving two unconnected vibrator synchronous reverse operation, force superposition centrifugal force two eccentric quality generated along the direction of vibration, reverse centrifugal offset, thereby forming along the direction of vibration induced vibration sieve box single, make reciprocating rectilinear motion.

- Q: How does a vibrating screen work in a rock yard? What is its principle?

- Powder application is very wide, are widely used in papermaking, rubber, paint, plastic aluminum, ceramics, cement, glass, metallurgy, refractory materials, medicine, food, cosmetics, daily chemical industry, construction, decoration and other advanced technology production field.

- Q: Environmental protection type sesame vibrating sieve

- Sesame specific rotary vibration sieve is mainly composed of a base, a damping spring, screen frame, screen, net cleaning device and an upper cover. This series machine by the motor for vertical vibration source, and the motor is installed at both ends of the eccentric weights, the rotary motion of the motor into a horizontal, vertical, inclined three sport then, this movement is transmitted to the surface of the screen, so that the material to do external involute motion on the screen, so this series of vibrating screen is called the three dimension vibration sieve. The vibration sieve has the material running track, the screen surface has a high utilization rate of phase, adjust the upper and lower ends of the hammer angle, can change the material in the sieve surface movement. It can do fine screening, screening materials of probability.

Send your message to us

Vibrating Screen-For Stone Aggregates and Ores

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches