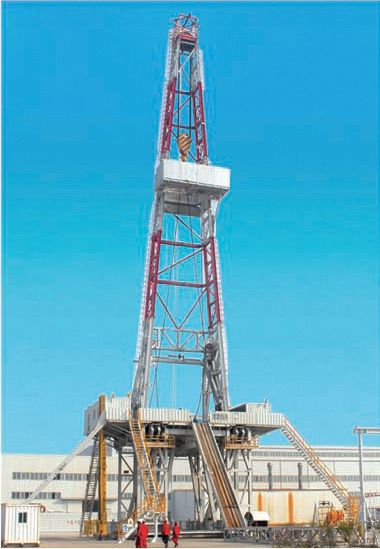

ZJ30/1700 Oil Drilling Rig

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZJ30/1700 Oil Drilling Rig

Introduction

3000m series oil drilling rigs are designed and manufactured for exploiting oil and gas well,

coalbed methane well, geothermal well, shale gas well and so on. The features of drilling rig are simples structure, easy operation, long durability. There are four kinds of models we can produce :ZJ30/1700, ZJ30/1700J(Belt compound), ZJ30/1700L(Chain compound), ZJ30/1700DB (AC VFD).

Main features

1. Mechanical transmission

2. Power: diesel engine+ decelerator

3. Speeds in gearbox become 4 forward +1reverse by gear transmission

4. Output shaft of gearbox transmit the power to drawworks by chain

5. Reasonable distribution of gears, high use ratio of power

6. ZP175 rotary table

7. Gear-shift of gearbox is controlled by pneumatic system

Main Technical Parameter

Model | ZJ30/1700 | ZJ30/1700J | ZJ30/1700L | ZJ30/1700DB |

Drilling depth (114mm drill pipe) | 3000m | 3000m | 3000m | 3000m |

Max hook load | 1700kN | 1700kN | 1700kN | 1700Kn |

Traveling system structure | 5×6 | 5×6 | 5×6 | 5×6 |

Fast line diameter | φ29mm | φ29mm | φ29mm | φ29mm |

Max.pull of fast line | 200 kN | 200kN | 200 kN | 200kN |

Power of drawworks | 515KW | 515KW | 515KW | 515KW |

Speed of drawworks | 4F +1R | 4F+2R | 4F+2R | 1F Stepless speed regulation |

Input power of rotary table | 200 kW | 200 kW | 200 kW | 200 kW |

Mast | JJ170/41-K | JJ170/41-K | JJ170/41-K | JJ170/41-K |

Substructure | DZ170/4.5-K | DZ170/4.5-K | DZ170/4.5-K | DZ170/6-K |

- Q: There are many types of gadgets and machinery stuff made by mechanical engineers. But what kinds are the most focus on and most popular?

- Dude, mechanical engineering is very broad and it's almost impossible to answer your question. But I guess I would say automobiles and electronic gadgets used in everyday life (computers, phones, medical devices). It all depends on where you land a job.

- Q: Examples being, Caterpillar bulldozers, skid steer loaders, front end loaders, steamrollers, etc.If so, what's the process of getting a license to do so?

- NO, you do not there are schools though that offer training as well as companies that provide on the job training. But there are not any licenses even for on the job trucks where you do not leave the job site.}{

- Q: Can you please just name the piece of machinery they used and in what mission? I want to be able to make my mom proud that I did my own work. Please help me?Here is the full question:Research a tool or a piece of machinery that scientists have used on a space mission. With your knowledge of simple machines, specifically describe how it was used to collect data for this mission. Include a diagram or picture (if possible) and be sure to list what mission this machine or tool was used on.

- The C.O.L.B.E.R.T. device (Combined Operational Load Bearing External Resistance Treadmill) has been used to exercise astronauts on the ISS. You can look that up.

- Q: I am not talking about homemade reloading. I'm talking about pooling up some money with some of my friends to buy commercial bullet/ammunition making machinery equipment, to manufacture our own ammunition from scratch, from the basic materials such as powder, lead, brass, and copper to the finished product = 1 fully assembled round of ammo.Due to the ammo shortage I see now, I see a great investment and commercial opportunity. Lead, copper, brass, and powder can be found in vast quantities, but ammo is in a shortage. But if I have the machines to melt, process, and combine these materials, I no longer have an ammo shortage. Where can I buy commercial ammo making machinery?

- In reality you WON'T save money by reloading 5.56,7.62x39 or 54R,there is just too much cheap stuff available and you will take too long recouping your costs when accounting for the press,dies,accessory equipment plus your consumables-and THEN add in your time. Reloading works well to gain accuracy or load for expensive or less supported cartridges-I reload for a 300 WSM instead of spending $40+ a box,so reloading for the other rifles is a bonus save/accuracy gain. If you had a WSM,Weatherby proprietary,RUM,RSAUM, boutique cartridges, 375 HH or larger;or things like a hot 6.5 x 55 Swede load,7mm Mauser,etc it would return your investment quickly. Your 300 Win Mag might get some accuracy gains and of course you can load specific bullets,but when you add a pistol cartridge you start needing a turret press instead of a single stage-almost doubles the press cost. Not going to dissuade you from reloading for what you can gain,but economically,it takes a while to see a benefit-and in the Russian loads you are dealing with questionable accuracy gains anyway. Best thing is to see what the Lee,RCBS,Redding,Hornady kits have in common-press,scale,hand primer, Lube Pad,etc-add to that a decent dial caliper,case trimmer of some type(Lee and RCBS take two TOTALLY different approaches),tumbler,and a bullet puller maybe.

- Q: What is the meaning of right in The boiler was in the fore-end, and the machinery right astern.

- In this context, it means that the machinery was behind the boiler. Right is used to mean right next to. Astern, being towards the stern, or back of the boat, gives you the direction. So, right astern means directly behind.

- Q: Is the construction machinery good? How about employment?

- Construction machinery technology will use new knowledge and new technology application of modern mechanical engineering technology throughout the practice has a certain reference and guidance value to the engineering, suitable for traffic construction and equipment, professional mechanical design manufacturing and automation professional and related professional courses teaching, but also can be used as engineering technical personnel reference data and other personnel training materials.

- Q: mainly in construction.

- Computerized machinery can cut labor costs by automating a lot of tasks. This a given worker produce more in the same time and is thus more efficient. It can also cut waste by reducing errors in measurements and assuring maximum use of raw materials.

- Q: mine is bumblebee. he's the be

- Wheeljack or SideSwipe. Jackin n Swipin is fun. eeep eep opp opp. transform!

- Q: My contractor table saw has 2hp motor first starts up caused my lights in my basement to dim and as it running seems like it has some shaking in it, I can feel in the saw table, also the basement light seems to flickering or diming out the whole time when saw is in used. Any idea what is the cause guys. I could use some advice here. By the way this motor is running on 110 volts 60 hertz.

- loss of power, [lights dimming] needs its own circuit blade out of balance, ,or loose

- Q: How is cantilever technology used in heavy machinery?

- anytime the load is extended out from beyond the structure, for example: 1 container cranes 2 shiploaders 3 ship unloaders 4 building a bridge over empty space (river, gully, road, railways) from both sides, especially evidenced in fixed stay bridges where the next segment is attached to the previous construction although the shooting bridge takes some of the loads 5 diving board at a pool

Send your message to us

ZJ30/1700 Oil Drilling Rig

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords