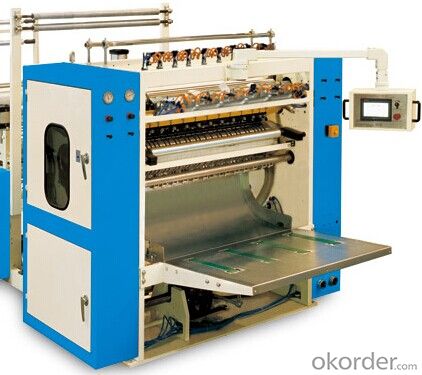

YH Facial tissue folder(900/1050/1260/1500)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. This machine line adopt the PLC control system, HMI, one button Chinese -English language switch, independent frequency conversion synchronous drive,and mechanic and photoelectric integration, and so on some advanced technology. Machine equipped with whole line self-detection system, it can observe itself during the productivity, keeping the machine line in optimal situation.

2. The folding roll and cut off roll are process with Computerized Numerical Control (CNC), also every roll adjust by the balance test to make sure the rolls can perform at high speed operation.

3. The edge embossing roll surface is cover by some special material and to be chromed.

4. Each back stand has two 160mm width unwinding blet, make sure the jumbo roll cann easily unwinded.

5. The machine would not slip when the machine stop urgently.

Unfolded finished product Y(mm) | 210/200/210(other sizes to be specified) |

2 ply of jumbo roll (gsm) | Single ply 13~18gram(other to be specified) |

Maximum jumbo roll diameter(mm) | Φ1500×900/1050/1260/1500(other size to be specified) |

Core size of jumbo roll | Φ76mm(other size to be specified) |

Machine speed | 110m/min |

Main power(KW) | 5.5-11.5(Depend on the machine model) |

Vacuum power(KW) | 15-30KW(Depend on the machine model) |

Control voltage(V) | 24 |

Cut off | With the upper blades stay still |

Machine framework | The metal plate and welding structure |

Paper detection | Web.break detectors throughout all the unit on the line and auto-stop |

Machine drive | Motor drive,reducer(with chain),timing belt,flat belt,chain,triangle belt |

Jumbo roll loading system | Pneumatic loading system |

Unwind stand | 2ply |

Distance of folding rolls | Adjustable |

Paper counter discharge system | Pneumatic paper discharge board |

Paper discharge system | Stepless speed control flat board |

Dimension(mm) | Depend on the machine model |

Weight (kg) | Depend on the machine model |

Option | |

Unwind stand | 4ply |

Embossing unit | Steel to steel,steel to rubber |

Edge embossing unit | Steel to steel |

Trimming system | Vacuum suction trimming |

Control system | LCD screen operation panel,MITSUBISHI PLC |

- Q: What is the general packing cost of beer beverage packaging?

- In addition, according to the product's own conditions to set, the packaging machine prices are generally in the range of 3-5 yuan

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- This situation is best to find after sale processing, you have difficulty adjusting normal

- Q: A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- (1) calculate the average of two samples;(2) the variance of two samples was calculated;(3) which packaging machine is more stable in packing quality?(1) according to the average, the number divided by the sum of each group;

- Q: Color code positioning of packaging machinery

- The main products are: packaging machinery series of quantitative packing machine, vacuum packaging machine, packing machine, strapping machine, sealing machine, bag machine, carton forming machine, packing machine, winding machine, labeling machine, stacking machine, and the design of various transmission lines; at the same time, the production and sale of packing tape, stretch film and other packaging material.

- Q: Working principle of packing machine

- In the first step, the wrapping paper is pulled down by a bag pulling motor, and then the paper part is supplied with paper according to the signal of the paper feeding sensor, and the wrapping paper is formed through the forming part of the shaper

- Q: What's the best place to use the pillow type packing machine?

- Suggest that manufacturers can find communication, there is no technical strength,

- Q: What is the name of the paper used in packing machine parts and yellow?

- Rust preventive action, commonly used for steel vapor rust preventive paper, but also for a variety of metals.

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packing machine? Should the packing of the tableware be contracted? Tak Cheung packing machinery, automatic heat shrinkable tableware packing machine can be considered

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- What is the size of the parison forming pressure and the performance of the ceramic wall and floor tile products?Ceramic wall and floor tiles are usually formed by pressing. Domestic made for 30 tons, imported equipment has tons of suppression, 200 tons and 500 tons. In order to smooth accurate size, excellent products, must pay attention to the effect of powder properties and compression of products. That is to say, the quality of the floor tiles, billets, methods of preparation, and the quality of products and production scale and way of pressing machinery. As for pressing pressure, as the molding pressure decreases, the sintering shrinkage becomes smaller and the water absorption rate becomes smaller, the durability of the product should be improved. It should be noted that the pressure should not be too high. Excessive pressure, stress, and density increase will cause unnecessary energy consumption, and cause compressed air to expand after pressure is canceled and cause excessive spalling.

- Q: What is a packaging machine?

- Meet the needs of mass production and meet the requirements of clean sanitationUsually some non-standard equipment, the common is pneumatic and simple combination of electrical components, to meet the requirements of factory automation

Send your message to us

YH Facial tissue folder(900/1050/1260/1500)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords