XL Sand Washing Machine,Mining Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Profile

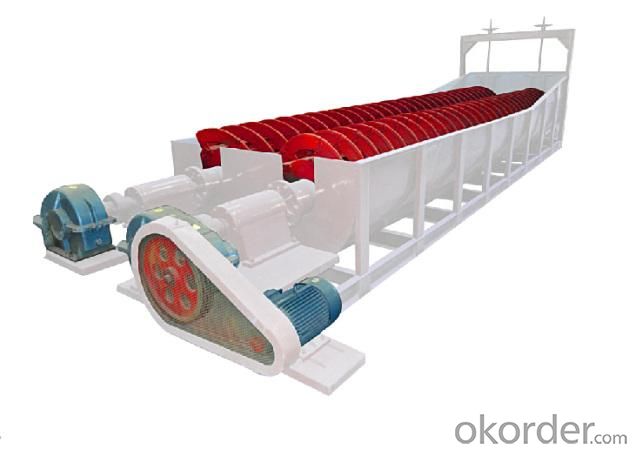

XL Model Sand and Gravel Washer is a kind of high efficiency bucket wheel washing equipment combined with sand making machine in domestic sand and gravel industry. The equipment has three functions of cleaning, dewatering and grading; it is suitable for construction site, sand and gravel plant, hydropower station, pressure sand in backfill of oil well’s cleaning, grading and dewatering. Suitable for fine grain and coarse particle size materials cleaning operation, it is especially suitable for building sand and road building sand. XL Model Sand and Gravel Washer can effectively deal with the material within 0-30mm, and the soil and ash powder can be washed into clean materials separately. This machine has the advantages of simple structure, easy maintenance and high washing efficiency and so on. Spiral sand washing machine is divided into double helix and single screw. Double helix spiral stone washing machine compared to the single screw spiral sand washing machine features high efficiency, high yield .

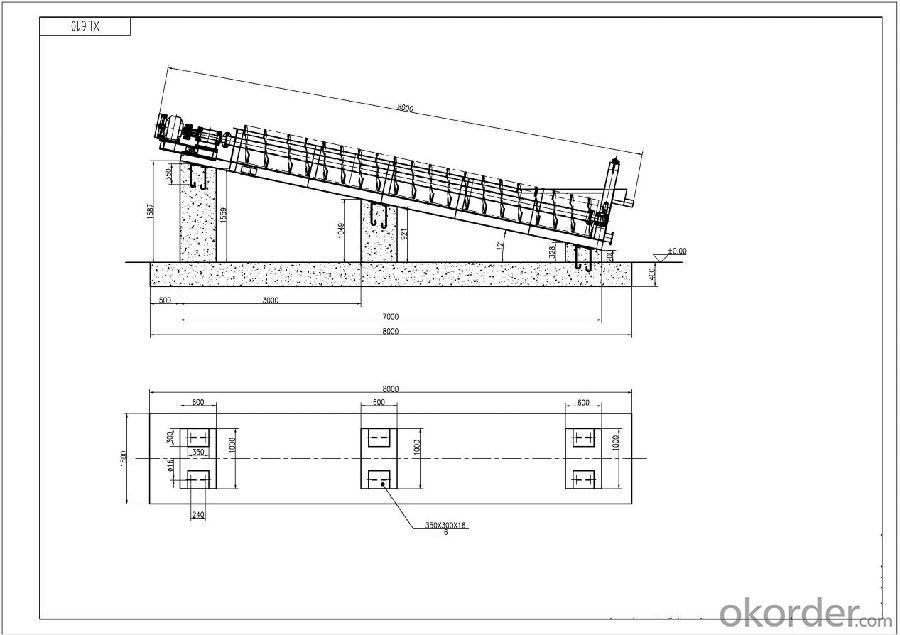

Overall Drawing

Technical Specification

Model | XL915 | 2XL915 | XL1115 | 2XL1115 | XL1370 |

Screw Diameter | 915 | 915 | 1115 | 1115 | 1370 |

Sink Depth | 7585 | 7580 | 9782 | 9782 | 10363 |

Feed Size | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

Productive Power | 100 | 200 | 175 | 350 | 250 |

Screw Rotation Speed | 21 | 21 | 17 | 17 | 14 |

Water Consumption | 10-80 | 20-160 | 20-150 | 40-300 | 20-250 |

Outline Size | 8420*2810*3960 | 8420*3765*3960 | 10970*3945*4720 | 10970*5250*4720 | 11420*4458*5326 |

Motor Power | 11 | 2*11 | 15 | 2*15 | 22 |

Weight | 6.2 | 11.1 | 10.2 | 17.9 | 15.3 |

* The above table is for reference only, and the actual application should be changed according to the customer's requirements.

Working principle

When the XL Model Sand and Gravel Washer working, after the motor is decelerated by V-belt, reducer and gear, then it drive the impeller to rotate slowly; Gravel from the feed tank into the wash sink, driving impeller to roll, and make the materials grind by themself. Remove the impurities what covering the surface of sand and gravel; At the same time, the water vapor layer of the surface sand is destroyed to facilitate dehydration. Then, fill water to form strong water flow, the impurities and foreign bodies with small specific gravity can be removed in time, discharged from the overiall of sink to complete cleaning work. Clean sand and gravel carried away by blades, gravels pours into gutter from the rotating impeller to complete cleaning work of gravel.

Feature

It has large processing capacity and small power consumption

The washing material loss is less, the washing power is high

The structure is reasonable and the operation is stable

Low failure rate and simple maintenance

Save water resources and no pollution

Long life and long term use without maintenance

Except sieve, there has almost no other vulnerable parts

Installation

The installation, adjustment and operation of the machine assembled by the manufacturer, and after passing the run-in test to supply, users should carefully check after receiving machines, in order to find the possible problems in transit. Attention should be paid to the installation, adjustment and operation of the machine:

- Due to the large torsion of the machine, it is suggested that the machine be installed on the concrete foundation, an pre embedded welding parts for installation welding on the foundation. The depth and area of the foundation are calculated separately according to the soil conditions, suggestion that the foundation weight be approximately 3 times the weight of the machine.

- After installation, should be checked whether the big size gear and small size gear of reducer is shifting, whether the water tank is in accordance with the clearance of the large wheel bucket. After the adjustment, fixed welding the machine on the foundation.

- Lubricating oil should be filled and adjust the height of the oil surface, generally take 50% below of the center shaft.

- After the installation and adjustment of the machine, the test run is carried out, no load test run should be reached:

1.Continuous operation for 2 hours.

All solid parts should be firm and no looseness appearance.

The reducer and gearbox without abnormal voice.

- In addition to the no-load test requirements, the load test should also meet the following requirements:

1.When feeding, can not make the materials strongly impact the water tank; Not allowed charging with unbalance loading and push the full water tank, in order to avoid to damage the bucket and the organism.

2.For the largest size material has been designed to meet the design requirements.

FAQ

1. What materials are used for helical blades?

- Commonly used material is wear resistant cast iron.

2. What are the structures of the machine and are they variable in length?

- The machine has two kinds of heavy and light, our company has the length of the standard configuration, also can according to the scene working conditions to provide customized service.

3. Whether or not to widen the sink of machine?

- Yes, and different sink types can be designed according to customers' needs.

4. Is machine maintenance convenient? How to maintenance?

- Our company provide convenient maintenance, high degree of modularization and 24 hours all-weather service, has five star service ability, makes service more timely.

- Q: Sand washing machine installation, debugging and maintenance strategy

- After passing the empty test, the platform is supplied. After the installation, adjustment and operation of the machine, it should be noted that the basic weight is approximately 3 times of the weight of the machine.

- Q: Is sand making machine good for single motor or double motor?

- There are many kinds of sand making machine, such as hammer type sand making machine, conical sand making machine, counter strike sand making machine, vertical shaft type sand making machine and so on. Different sand making machines require different motors. Therefore, the sand machine does not matter single motor or double motor good, manufacturers will be based on different principles of sand machine choice with a single motor or double motors. Manufacturers are equipped with the principle of low energy consumption and high output, or else they are not competitive.

- Q: What is the working principle of a screw cleaner?

- Long spiral sand washing machine is composed of motor, reducer, tank, central shaft, spiral blade and a bracket.

- Q: Under what circumstances are double spiral sand washing machines available? What are their advantages?

- In the use of double spiral sand washing machine should pay attention to the use of the following safety rules: 1, exceeding the prescribed size cannot join the stone; 2, sand washing machine is in operation before the first hand of rotation of the rotor and check each part of double spiral sand washing machine has no strange; 3, sand washing machine is in operation, not able to work repairing and cleaning; 4, customers according to the site of sand washing machine operation, installation of protective equipment in triangle belt, in order to operate.The utility model has the advantages of reasonable structure, large processing capacity, high washing degree, small loss of the middle and fine sand, and the transmission part of the utility model is isolated from water and sand, and has no abrasion.

- Q: What items should we pay attention to in the construction of sand aggregate production line?

- Aggregate sand production line equipment: jaw Hengchang Metallurgical Building Material Equipment Factory production of crusher, impact crusher, self centering vibrating screen, sand washing machine, washing machine.

- Q: How does sand washing machine clean sand and gravel?

- Before using, use sand washer to clean the sand, dry or dry.

- Q: What's the usual trouble with the sand washer?

- The protection plate protects the bottom of the tank, sometimes the impeller is stirred to accelerate the crushing of the rock, and if the motor load is suddenly increased, the accident can be caused seriously. Therefore, in the boot, pay attention to adjust the gate, keep the stone surface stable, so that sand washing machine normal operation.

- Q: I wash Sunaba sand washing process

- Sand washing machine adopts advanced technology, combined with the actual situation of domestic sand industry developed efficient sand washing equipment, it has washed height, reasonable structure, high yield, less loss of sand sand washing process, especially the transmission parts with water, sand isolation, so the failure rate is much lower than the currently used sand washing machine, is the best choice for the domestic washing sand industry upgrading.

- Q: How much dirt and debris can be washed at one time?

- The model is different and its workload is differentTake XL type as an example,XL915 can clean 100T per hour, while 2XL1115 can clean 350T. every hour

- Q: GX series spiral sand washing machine is better than the general spiral sand washing machine? What's the difference?

- GX series spiral sand washing machine adopts foreign advanced technology level, and is the best choice for domestic sand washing industry upgrading.

Send your message to us

XL Sand Washing Machine,Mining Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords