XL Series Sand Washing Machinery for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

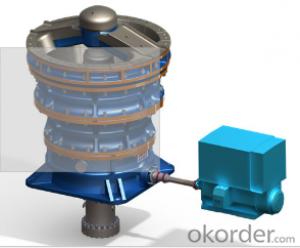

XL Series Sand Washing Machinery is generally used to clear up and remove the dirt and contaminate mixed in sandstones. Novel sealing structure, adjustable overflow weir and reliable transmission system could fully ensure the complete washing and dehydrating. It is suitable for washing fine granularity and heavy granularity, and frequently used in industries in need of sand including highway and constructions.

Description of XL Series Sand Washing Machinery

XL Series Sand Washing Machinery is widely used for distributing ore in the close circuit with ball mill, grading ore and fine slit in the gravity mill, grading granularity in the flow of metal ore-dressing and desliming and dehydrating in the washing. Advantages are simple structure, reliable working condition and convenient operation. According to the principle that different grains are with different specific gravity and sedimentation rate in the liquid, the fine ore flows in the water and the coarse ore sinks in the bottom. The classifier that has machine grading by discharging from the top can filtrate the materials and send coarse materials to the feeding mouth and discharge the fine material from the pipe. The seat of the machine adopts channel steel and body adopts armor plate and the spiral axle adopts cast iron, so it’s durable. The lifting equipments have two types, by electricity and hand.

Working principle of XL Series Sand Washing Machinery

The XL Series Sand Washing Machinery eliminate the impurities by the buoyancy of water ,as we all knew the specific gravity of various materials are different ,so when XL Series Sand Washing Machinery on operation , the spiral scatters will rotating , the strength of rotating spiral scatters will push the water going forward , at the same time , the light specific gravity which is mean the impurities will flowing with water , but the clear sand mater will fell down and going forward also by the strength of spiral scatters .this the way how XL Series Sand Washing Machinery doing .

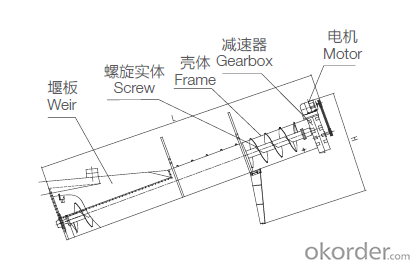

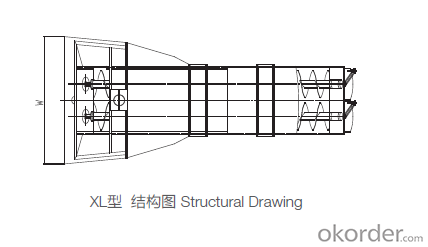

Consist of XL Series Sand Washing Machinery

The XL Series Sand Washing Machinery consist of cell body, speed reducer ,motor power ,central shaft, spiral scatters, support parts.Sentai Mining Factory is the real good producer of XL Series Sand Washing Machinery,which has years experience of how to producing the quality XL Series Sand Washing Machinery with stick steel plate . We can supply almost all the machine which connecting with beneficiation .

Our main product :hammer crusher , rotary dryer ,ball mill ,magnetic separator ,flotation separator .

Sand Washer Technical Parameters

| Model | Screw Diameter (mm) | Tub Length (mm) | Selected Granularity (mm) | Processing Capacity (t/h) | Screw Speed (r/min) | Motor Power (kw) | Water Consumption (t/h) | Overall Dimension (L×W×H) (mm) | Weight (t) |

| XL915 | 915 | 7585 | ≤10 | 60-100 | 21 | 11 | 60-80 | 8500×2810×3600 | 6.27 |

| 2XL915 | 915 | 7585 | ≤10 | 120-200 | 21 | 2×11 | 120-160 | 8420×3765×3960 | 11.11 |

| XL1115 | 1115 | 9782 | ≤10 | 100-175 | 17 | 18.5 | 100-150 | 10970×3945×4720 | 10.7 |

| 2XL1115 | 1115 | 9782 | ≤10 | 200-350 | 17 | 2×18.5 | 200-300 | 10970×5250×4720 | 17.94 |

| XS2610 | 2600 | 3220 | ≤10 | 30-50 | 1.2 | 5.5 | 25-40 | 3220×2125×2670 | 3 |

| XS3016 | 3000 | 3810 | ≤10 | 50-80 | 1 | 15 | 40-60 | 3800×3 |

- Q: How much money which the stone washing machine, stone washing machine of good quality and reasonable price.

- Reasonable price is the absolute principle. Look at your judgement. Big factories must be expensive. As long as you are not the next set of cheating, small factories can buy cheaper and more suitable equipment. You've known the 5. Of course, the best is not the manufacturers of the industry guidance.

- Q: Under what circumstances are double spiral sand washing machines available? What are their advantages?

- The double spiral sand washing machine produced by bailing machine can handle the materials within 0-30mm, and can clean the soil, dust and powder on the material. The utility model has the advantages of simple structure, easy maintenance, high washing efficiency and the like.

- Q: What is the installation process of the sand recovery machine? Is it difficult to install?

- High pressure separator: steel bearings will return bend and outlet docking will be installed in the high-pressure separator feed back on the box, the lower end is inserted into the pipe back to the material box and the upper cover plate and welding, sand recycling equipment high pressure separator the front end of the feed box, loading and fastening bolt. Fill the 76mm feeding rubber tube, the lower end is connected with the pump outlet pipe and tightened with wire.

- Q: How to make the use of spiral sand washing machine handy?

- The production capacity is large, and the sand powder and the mud powder content are low, and the produced sand material is used in a large number of occasions, which brings great benefit for the sand and gravel industry.

- Q: The working principle of sand washing machine

- Large processing capacity, low power consumption;

- Q: How to avoid gear damage when using sand washing machine?

- When installing, be sure to do a good job of foundation, to ensure that the foundation is smooth, so as to reduce the phenomenon of gear wear;

- Q: What are the differences between the dry sand making method and the wet sand making method?

- Wet sand process and semi dry sand process the biggest difference is broken in different ways, the former is broken ground, and the latter is mainly to break, impact, therefore, can be used wet sand rod mill, impact type sand making machine or centrifugal sand making machine, and half dry sand making machine only the use of sand making process of sand making machine with vertical impact, this is the biggest difference between the two.

- Q: I wash Sunaba sand washing process

- Estimated that ordinary people will not, ha ha, you should go to someone specially designed ah!

- Q: What's the difference between spiral sand washing machine and spiral classifier?

- Screw conveyor profile: screw conveyor series in all kinds of powder or granular materials conveying has a wide range of applications. The screw conveyor is made of carbon steel and is machined on the surface. The conveyor consists of the following components: equipped with at least one outlet of the U type or V type tank, baffle tank at both ends of the welding in the center of spiral blade on the tube, central tube connection sleeve at both ends of the two shaft end bearing assembly includes a sealing unit, the middle hanging bearing cross-sectional area by a screw conveyor of the total the length and bolt connection groove to determine the number of. In addition, in order to meet the demand, the screw conveyer is also provided with a reduction box and an electric motor. According to the different conveying materials, the screw conveyor is designed with three kinds of light load, heavy load, medium load, heavy load, heavy load and heavy load.

- Q: Washing sand recovery machine, sand washing machine manufacturers how much?

- Sand washing machine we produced is the use of advanced technology at home and abroad, the domestic actual situation of sand industry development of sand making machine using high efficient wheel sand washing equipment with the production of large capacity, small power consumption and simple maintenance, stand in the customer's perspective, with minimal investment for maximum benefit.

Send your message to us

XL Series Sand Washing Machinery for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords