Industrial bucket sand washing machine|Wheel Dou type sand washer|Sand washing machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

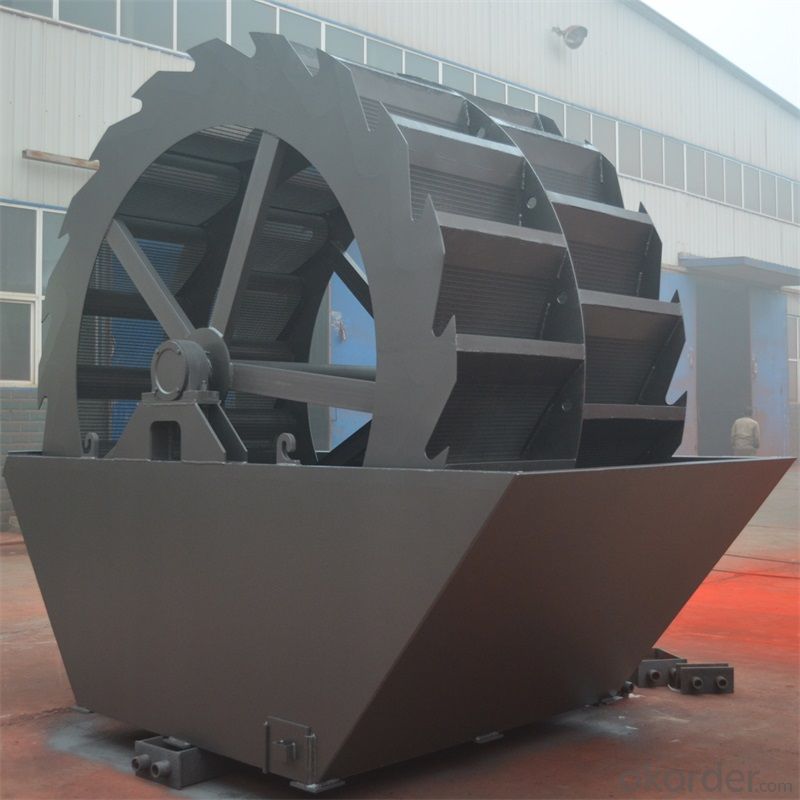

Brief Introduction of Industrial bucket sand washing machine

XS series high-efficient sand washer is the necessary wheel and bucket sand washing equipment, which is used with sand making machine. It can wash stone powder and residual away from the mixed sands produced by sand making machine to improve the quality of sand. It is produced by considering the home sand industry situation, which is widely used to wash,fractionate and dehydrate in sandstone factory,sand factory,hydroelectric concrete dam,concrete casting basin,glassworks quartz sand and pressure oil backfilling sand. High clean ratio,reasonable structure,high capacity,low powder cost and less waste are its features. Especially its transmission parts are isolated from water and sand to reduce the malfunction compared with traditional sand washer. And it is the best choice if you want to upgrade the product.

Advantages of Industrial bucket sand washing machine

1. High cleaning;

2. Reasonable structure;

3. High capacity and low power consumption;

4. With the three functions of sand washing, grading and dehydration;

5. The sand washing machine is 15°tilted layout;

6. The spiral is driven by motor and decelerator to continuously rotate, and the sand or small ores can be stirred and washed.

Technical Parameters of Industrial bucket sand washing machine

Model | Impeller dia. (mm) | Feeding size (mm) | Capacity (t/h) | Power (KW) | Weight (kg) | Dimension (mm) |

XS 2615 | 2600×1500 | ≤10 | 30-80 | 7.5 | 2700 | 3320×2200×2670 |

XS3016 | 3000×1600 | ≤10 | 80-160 | 18.5 | 4300 | 4500×3206×3480 |

XS3500 | 3500×1000 | ≤10 | 120-600 | 11 | 9900 | 4420×2930×3800 |

- Q: Cobble stone production line equipment is a how much money

- Sand gravel by equipment set hopper, feeder, crusher, crusher, vibrating screen, sand making machine, sand washing machine, conveyor. Of course, it can be simplified.

- Q: The sand is not washed and the mud content is 2

- Wet sand production line, after the sand and sand washing machine is not very clean, large amount of mud and sand Wet (water), does not meet the production needs of sand mud with low content of high standard, after dehydration sieve two times washed sand, hydraulic classification, desliming, dehydration, implementation the reasonable ratio of particle size, the amount of mud drop below 0.7%.

- Q: What are the main parts of the spiral sand washing machine?

- Spiral sand washing machine is also called sand washing machine, washing machine, mainly used for sand products to remove impurities (such as dust) of special machinery and equipment for cleaning, because many stone building materials, it is also called the washing machine. The machine rotor of the spiral sand washing machine adopts the central structure, the spiral blade is installed on the central shaft, and the reducer is connected to the central shaft to work. A device for a mechanical extension by means of the principle that the specific gravity of a solid particle varies so that the rate of settling in a liquid is different.

- Q: I want to contract a sand and gravel factory, but I am a layman. I don't understand anything. Please help my brother and give some advice

- I do is sand factory, run about 2 million or so, to run the mining permit, the demolition company signed a good contract, probably around 100 thousand he gave you put a gun, bought lithotriptors yarn machine and other equipment 80 thousand, two forklifts 400 thousand, 18 in case a few years ago now expensive.

- Q: Years of building concrete with washed sand

- Washed sand mixed concrete buildings, service life: 50 years.

- Q: I want to buy a sand washing machine to wash artificial sand, but I don't know what it works

- When working, power device reducer, belt, gear reducer drives the impeller to rotate slowly through the sand from the feed chute into the washing tank, roll driven impeller and grinding each other, remove the gravel covered surface impurities, while destruction of water vapor - coated sand layer, in order to facilitate the dehydration;

- Q: How many kinds of belt are there in the sand washer?

- A machine used for washing sand in a trough by means of a rotating spiral. In the process of washing, the sand washing machine can rush the fine particles in the sand, so it is also called a spiral classifier. The utility model is composed of a steel flume body, a spiral body, a power transmission device, a spiral lifting device, etc., and the water tank body is inclined to be installed, and the inclination angle is generally between 12 DEG C and 18 DEG C.

- Q: Difference and characteristics of dry sand production line and wet type

- Sand production line is generally divided into two kinds of dry sand production line, sand production line common are the following categories of equipment: sand making equipment, transportation equipment, crushing equipment, screening equipment, sand washing equipment, milling equipment. Basically, the above is the sand production line of the general configuration, and its process basically includes the jaw crusher as the first broken task, followed by sand making machine. Sand making machine is a kind of mechanical equipment in the sand and gravel, which is transported by belt conveyor, and then screened by vibrating screen.

- Q: Installation, adjustment and operation of SX type sand washing machine?

- After the installation and adjustment of the machine, the test run shall be carried out and the no-load test shall be carried out:1) continuous operation for 2 hours:2) all solid parts should be firm and free of looseness;3) reducer and gear box are all normal sound.5. the load test shall meet the following requirements in addition to the no-load test run requirements:1) when feeding, the material can not be strongly impact the tank, not allowed to load, feed and fill the tank, so as not to damage the bucket and airframe. 2) to the maximum size of the material to meet the design requirements.

- Q: What is the working principle of the sand washing machine?

- At the same time, water is added to form a strong water flow, and foreign bodies with small impurities and small proportion are removed in time, and discharged from the overflow washing tank for cleaning. Clean sand and gravel taken away by the leaves, and finally gravel from the rotating impeller into the trough, complete the cleaning role of sand and gravel.

Send your message to us

Industrial bucket sand washing machine|Wheel Dou type sand washer|Sand washing machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords