wpc wall panel, wpc decking floor,outdoor WPC wood flooring easy installed wpc composite decking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Features of the WPC Decking:

1. Recyclable, Eco-friendly, saving forest resources

2. With the look of the natural wood, but less timber problems

3. Moisture/water resistant, less rotten, proven under salt water condition

4. Barefoot friendly, anti-slip, less cracking, less warping

5. Requires no painting, no glue, low maintenance effort

6. Weather resistant, suitable from minus - 40 to 60 centigrade degree

7. Termites and insects resistant, and moldy-proof

8. Easy to install and clean

Specification of the WPC Decking:

component | 30%HDPE(Grade A Recycled HDPE) 60%bamboo/wood fiber component 10%chemical additives New material capped outside |

Size | 140X20mm |

Design | Solid decking |

Length | 2.9m/pc standard length, also from your required |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE,Walnut,graystone,Cedar,Rosewood) and we can adjust the new color according to the order requirement |

Cerfiticate | ISO9001, ISO14001, CE, FSC Certificate,"REACH"Test Reports by SGS; Intertek Test Report by ASTM standard..etc. |

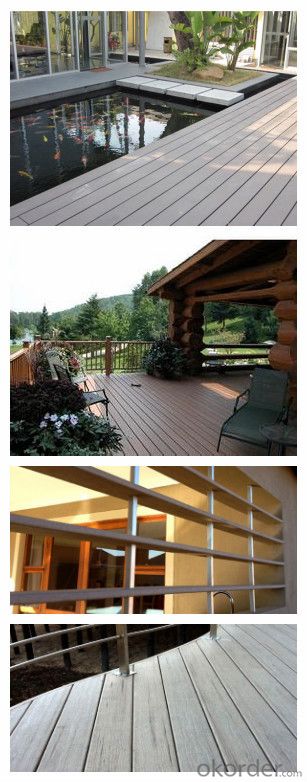

Images of Co-extrusion WPC Decking:

FAQ of Co-extrusion WPC Decking :

1. Available Colours?

5 regular colors to choose ( IPE,Walnut,graystone,Cedar,Rosewood )

2. How to Install?

3.Treatment for Option

- Q: Solid wood composite floor moisture it?

- As long as the wood are not moisture-proof or short-term spill can not sprinkle for a long time do not clear the leak into the gap in the consequences that can be small can form a big hidden deformation of the wood is also the same business that moisture Are JB nonsense what the closure of the wax tube can not use the focus or their own maintenance of the other are nothing

- Q: Strengthen the composite floor of the inspection standards which

- 1) wear index 2) formaldehyde content 3) expansion rate 4) flame retardant

- Q: Benefits and effects of composite flooring? Do you buy more people?

- Composite wood flooring is very wear-resistant, resistant to scratch, not easy to deformation, and easy to clean, easy to install.

- Q: Home before the shop floor of the composite floor, there is a room under the bed is always moldy, with a dry towel, the towel will have a damp feeling, can be gallbladder broom prostitutes poor Wei Wei is the floor is not deformed. Does anyone know what reason? Questions added: there is usually the room that no one lived. More

- If it is solid wood flooring, there may be long hair, but first of all to find out the corner of the wet moldy reasons, usually such a situation there are several possible, 1, the ground back tide, waterproof layer did not do well, Pipe water leakage, 3, the ground water is not good, the ground water into the wall solid wood flooring maintenance of solid wood flooring to do moisture maintenance, in addition to a simple timely window, often ventilation, there are more professional methods: Care. Should be half a year or a year to play a wax, so you can make the solid wood flooring to avoid the rainy season when the invasion of moisture, so as to achieve the purpose of extending life. Usually in the care of solid wood flooring should also be careful not to let moisture into the solid wood flooring. When found solid wood flooring surface mildly when the time can be used in a timely manner with a soft bleach to 1: 3 dilution ratio of mixed wipe, and then wipe clean cloth.

- Q: My house decoration, the boss gave us to pay off the grass barnyard grass carpets, but the floor of the floor, and because of the uneven floor, after the shop a wall to another wall difference 10 cm or more, the cup can clearly see the tilt, it means that I sleep is head down feet up, ask what way to solve. More

- This can certainly be floor uneven, the solution is to the floor and the following mattresses demolished, re-leveling, and then do not use the installation of the floor when the treasure!

- Q: Why is it better to use solid wood flooring?

- Why is it better to use solid wood flooring?

- Q: Strengthen the first floor of the composite floor when the installation of the tank to the wall?

- Protruding part of the wall, the right slot is the groove, when the shop to another wall when the last piece of the board can not be just when the release of the river burning incense if the extra part can be cut Cut off the machine

- Q: I am all inclusive to the decoration company. Decoration company recommended to strengthen the floor under the floor put mat, their reason is the guest restaurant and corridor paste tiles, if the bedroom keep the pad is not the same height. But my friend suggested that I strengthen the composite floor under the release of moisture-proof pad, helium Fu Fu Huang Bing Hao Feng kettle pad to keep a long time will be uneven. In the end which kind of better please enlighten God. More

- If it is a pavement treasure, there is a drawback, that is, some places will have a squeaky sound, feeling particularly soft!

- Q: Solid wood composite flooring discoloration is what reason

- Wood light color reaction Wood color is mainly caused by the absorption of ultraviolet light, timber sapwood and heartwood to absorb ultraviolet light after the degree of discoloration, will lead to pavement after the floor to produce a certain color. Multi-layer parquet surface for the natural wood, with the natural properties of wood, resulting in light color is a normal phenomenon, not a product quality problems. China 's wood flooring prompted the majority of wood discoloration reaction 窢 籂 籂 dumpling 讵 讵 存 担 担 担 Long is deep and shallow, only a few wood is deep and shallow, in the same floor of the discoloration is basically the same.

- Q: We got an Engineered wood floor installed after a month it started to get soft then made popping sounds as I walked over it. The floor was sealed for moisture then a recommended glue was used to put it down, as the floor was being laid, weights were put on the floor for several days to allow the glue to stick, but alas it started to pop. can anyway one explain this, as I now have to re-drill the floor and inject glue to re glue it. any one have nay suggestions or explanations? Thank you.

- You have the answer, just do it. weight it down until the glue dries. You can even use white wood glue.

Send your message to us

wpc wall panel, wpc decking floor,outdoor WPC wood flooring easy installed wpc composite decking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords