Wpc outdoor diy deck/wpc composite diy boardwalk deck

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

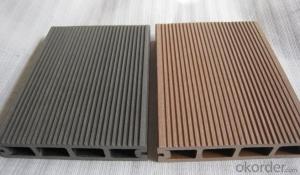

Main Features of the WPC Decking:

1. Recyclable, Eco-friendly, saving forest resources

2. With the look of the natural wood, but less timber problems

3. Moisture/water resistant, less rotten, proven under salt water condition

4. Barefoot friendly, anti-slip, less cracking, less warping

5. Requires no painting, no glue, low maintenance effort

6. Weather resistant, suitable from minus - 40 to 60 centigrade degree

7. Termites and insects resistant, and moldy-proof

8. Easy to install and clean

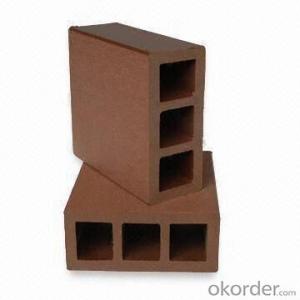

Specification of the WPC Decking:

component | 30%HDPE(Grade A Recycled HDPE) 60%bamboo/wood fiber component 10%chemical addatives New material capped outside |

Size | 140X20mm |

Design | Solid decking |

Length | 2.9m/pc standard length, also from your required |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE,Walnut,graystone,Cedar,Rosewood) and we can adjust the new color according to the order requirement |

Cerfiticate | ISO9001, ISO14001, CE, FSC Certificate,"REACH"Test Reports by SGS; Intertek Test Report by ASTM standard..etc. |

Images of Co-extrusion WPC Decking:

FAQ of Co-extrusion WPC Decking :

1. Available Colours?

5 regular colors to choose ( IPE,Walnut,graystone,Cedar,Rosewood )

2. How to Install?

3.Treatment for Option

- Q: This question is also under remodeling.I'm considering installing Thomasville's Walnut engineered flooring, or solid Bamboo flooring from home depot throughout my upstairs. I would appreciate hearing from anyone that has installed either of these products.Specifically, do either of these floors dent and scratch easily? I have three cats, two children and my massage business in my home.Does one of these outshine the other? Does either hold up as well as any other product you might have experienced? Do you know of anyone who has used these? They are similar in price, so that is not a factor. Thanks and I look forward to input anyone can provide!Additional details: It looks like all the interlocking floors come pre-finished. All the others I'd have to stain and poly myself, correct? Since I don't build homes, I'm going for a balance between easy install and quality. Thanks!

- i know the solid abmboo would be the way to go for me...its a great product

- Q: Composite floor sound how to deal with

- Solution: (1) with the muffler if the floor is not sound, or local sound, and maintenance is not convenient circumstances, you can first buy a special wood muffler smear, a slight noise can be eliminated, If the sound is too large to a certain extent, reduce the maintenance at the appropriate time. (2) local resurfacing will be abnormal sound knocked out, Dilong handle the new floor to fill in. (3) all resurfacing If it is because the floor itself, or the pavement process is not compliance and other issues, resulting in a lot of places where the sound, or the ground did not leveling, the proposed resurfacing, the cost of all the resurfacing When the sub-shop, pay attention to the ground leveling, to ensure that the ground leveling layer leveling you want to have enough dryness, to ensure that moisture content within 8% to lay the keel, if it is wood keel, brush pest and paint a paint, Or perennial in the rainy and humid season, then the keel can also add a layer of wool floor or linoleum, so as not to deformation of the floor moisture, laying a good attention to the maintenance of the floor.

- Q: How do you see the quality of composite flooring?

- How do you see the quality of composite flooring?

- Q: Can tile flooring be on the floor?

- Can, and tiles to install the wood floor is better than the cement better, because the installation of wood flooring requirements of the ground floor of the floor height is higher, the ground flatness difference of more than 0.5 cm, then stepped on the empty, it will creak creak Of the ring, very annoying. Tiles installed on the floor will not have this situation, but the only drawback of tile installation floor is the impact of the height of the house, it seems a little shorter. But it will not be too obvious, because the wood floor of the last general only 1.8 cm, the thinnest 0.8 cm, it is recommended that you install 1.2 cm. I believe you can rest assured that the equipment, certainly no problem, I have done more than six years of the flooring industry, so I see more of the problem. There is doubt you can also go to my shop to question hair dug out of the exhortation of non-stone single Insider.

- Q: Home recently in the busy decoration, ah, do not know what brand to buy the floor of it, a friend recommended peace of mind, useful to say that Kazakhstan, thank you. More

- China's multi-layer solid wood flooring one of the top ten brands of living multi-storey solid wood flooring China's multi-layer solid wood flooring one of the top ten brands of multi-layer solid wood flooring China's multi-layer solid wood flooring one of the top ten brands of natural multi-storey solid wood flooring One of the top ten brands of solid wood flooring North American maple multi-storey solid wood flooring China's multi-layer solid wood flooring one of the top ten brands of multi-storey solid wood flooring China's multi-layer solid wood flooring ten slips taste rough jealousy A multi-layer solid wood flooring one of the top ten brands of high-grade solid wood flooring one of the top ten brands of multi-layer solid wood flooring in China. Than the multi-layer solid wood flooring China's multi-layer solid wood flooring one of the top ten brands of natural multi-layer solid wood flooring

- Q: I want to choose composite floor price of 30-40 yuan or so (quality to go to), which brand of suitable for some?

- If only the floor price, what is not the package, even the freight is not included, so that the floor can be used at home. If it is packaged with other shipping costs, installation costs, etc., then the floor is not recommended to buy. Poor quality, used at home after a problem. For a floor, think of moving furniture, and then re-shop, energy and costs are high. [Bell floor, home, dream starting point]

- Q: Manufacturers said that the composite wood floor is not on the glue, but the information on the Internet that must be on the glue, ask the question: 1 must be on the edge of Gong Chi folder Jurassic grass Wei Wei even? 2 what is 3d glue? How to identify good and fake glue? What brand is better? 3, the scene how to monitor the glue is full? More

- Composite wood flooring installation, only the local brush glue, no full coating

- Q: Want to buy a good quality, save time and effort but do not hurt the floor of the mop. More

- You can consider the top of the rotation of the mop ah, his mop head is ultra-fine fiber, and the rotation of the dragons of the gangs of the tower is the machine is too water, so that will not let the mop because too much water, so The floor is hurt. In addition the quality of the topology is also very good, with a one or two years no problem, his mop head will not be the same as the other at every turn on the hair loss.

- Q: What is the meaning of the composite floor suspension installation?

- Suspension is the name of the suspension, that is, the floor below the plywood or wood keel fixed, no nails, no glue, by the earth force, flat on the level of the ground, by furniture, foot line to suppress. Removable, can be installed, can be moved, can change function. This is a new installation method. First, the floor anti-accident function is strong, the so-called accident, nothing more than careless floor dipping water arch, then the floor board can be removed and the floor is not damaged. Second, if flat, then walking without sound, foot feeling very good, with the natural wood of the floor flexibility. Thirdly, this is the only thing that will not be devalued after the home decoration. Imagine that if the household uses a floating floor, the second time after ten years of renovation, the floor can be removed and returned to the factory. In theory, it is entirely possible to do it. The existence of this objectivity is undoubtedly another great contribution to the national environmental protection, in short, can be reused. Because it is suspended installation, floor flatness is built on the floor flatness above, so the ground must be leveling.

- Q: What is formaldehyde in the composite floor?

- Of course The

Send your message to us

Wpc outdoor diy deck/wpc composite diy boardwalk deck

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords