WPC Crack Resistant Decking Hot Sell Traditional Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of WPC Crack Resistant Decking:

A safe, environmentally responsible alternative to traditional decks, conserving energy and resources. Not only does this save your time over the maintenance, but it will save you money as well.

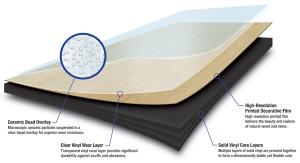

Composition of WPC Crack Resistant Decking:

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

Advantage of WPC Crack Resistant Decking:

· Maximum length: 6m

· UV resistance, durable

· Safe, environmentally responsible alternative to traditional decks, conserving energy and resources

· Low maintenance

· 100% recyclable

· Saves forest resources

· With look of natural wood but no timber problems

· Moisture/water-resistant

· No rotten, proven under salt water condition

· Barefoot friendly, anti-slip, no cracking and warping

· Requires no painting and glue

· Weather-resistant

· Termites, insects and moldy-proof

· Easy to install and clean

· Available in various colors

· Can be used in Temperature: -40 to +60°C

Installation of WPC Crack Resistant Decking:

Correct installation needs your high attention!

1 Always leave space (5-7mm) between 2 boards, or between board and wall.

2 Where there are 2 board ends meet, put 2 pcs of keels under each board end.

3 Keep the space of 2 keels at 25-750px.

4 Do not use glue to install.

5 Do not use our product where is always wet and sunless.

Other Information of WPC Crack Resistant Decking:

HS code: 3918909000

Time for production(1x20fcl): 15 days

Warranty: 10 years.

Certificate: CE, ISO

- Q: Wood floor moistureproof can use plastic film?

- Moisture proof performance is the most important technical index. Moisture proof performance of the floor, in the geothermal long time, steaming, once there is moisture into

- Q: How long can be used for plastic floor restaurant

- There are many types of plastic floor, mainly divided into coil and sheet, is the most common material, plastic sheet flooring series of thousands of species, like the current popular commercial floor plastic floor (PVC floor such as shopping malls, hotels, hotels, hospitals, schools, kindergartens, families, offices, airports, sports floor) (special stadium, badminton, table tennis, basketball, gym, dance floor (kindergarten), dance room, dance room, dance hall, dance rehearsal hall, dance studio, stage, ballet, Latin dance, dance practice room, dance room, dance training room)

- Q: There is a layer of plastic on the floor of the room

- The ground cushion treasure is a new type of lightweight sheet made of polystyrene resin and other additives. The utility model has a continuous uniform and dense surface layer and a closed cell structure, and the wall of the honeycomb structure has the same thickness. Therefore, the utility model has the advantages of superior thermal insulation performance, good moisture resistance, long durability, high compression resistance and good sound insulation effect. And it is non-toxic environmentally friendly products.

- Q: Self adhesive stone plastic PVC floor leather will not stick it

- PVC floor stone floor self-adhesive plastic free, that is, do not glue, the ground clean directly on the ground just fine.

- Q: Home decoration can use plastic floor it?

- () the name of the PVC floor is easy to cause people's misunderstanding, referred to the PVC we think more is plastic, a lot of people will be confused with the PVC floor and PVC pipe, plastic containing toxic substances harmful to the human body. But the PVC plastic floor and is not the same thing, PVC can also be called PVC, PVC floor 100% does not contain toxic substances such as formaldehyde and benzene, no radiation, which belongs to the green decoration materials, will not cause harm to human body. There is also concern for the construction of glue will not contain formaldehyde, should recognize a lot of bad business to reduce costs, the use of glue quality is not good, how much will contain toxic substances, glue but now well-known brand manufacturers are used in the construction of special glue, a green environment-friendly glue, do not have to worry about the release of formaldehyde other harmful substances.

- Q: Stone plastic film anti slip floor tile is a plastic floor or floor tile

- The main raw materials of stone plastic membrane Fanghuadezhuan said from the product, production process and performance characteristics, because it is the main raw material made of natural (non radioactive) marble and natural resins, so called stone plastic tiles. Performance: powder content is high, so its thermal expansion coefficient is small, high strength

- Q: Plastic floor joints how to deal with?

- Cold welding: when the plastic floor laying is completed, the use of cold liquid, cream or cold welding to connect floor seam.

- Q: How much is a square floor of plastic floor?

- Durability: the product of raw materials for polypropylene (PP) for high strength materials, added with anti ultraviolet radiation, anti oxidant, cold resistant materials such as modified polypropylene, the advantages of the products with pressure, impact resistance, high temperature, long service life etc.. High weather resistance, high temperature, humidity, rain is not afraid of the sun, never warping deformation beneath the bitter snows. There is no climate zone restrictions, no water after the site

- Q: What is the price per square metre of plastic floor?

- And the price of this plastic floor in accordance with the use of different location, the difference between the laying of a slightly larger, then there will be some differences in prices. This is a common phenomenon.

- Q: What are the main construction process of laying plastic floor

- (2) soft plastic floor plate:Primary treatment, elastic line, plastic floor wax, degreasing, pre laying groove blanking, scraping, paste, welding, rolling, maintenance.

Send your message to us

WPC Crack Resistant Decking Hot Sell Traditional Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords