Worm Gear Reducer For Extruder Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 40 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Worm Gear Reducer For Extruder Machine

Product Description

gearbox for conical twin-screw Rod Extruder is a special driving unit matched with conical twin-screw rod extruder.It consists of two parts,namely,the reduction box and the distribution box. After reducing speed and increasing torque of the motor,it outputs the motive power to the distribution box,then drives the double output shafts(the included angle is the same with that of twin-screw rods)via a pair of small conical spiral gears with driving ratio of 1:1,thus to drive screw rods to rotate outward with different direction.

Adopting latest standard ISO1328,the precision of cylindrical gear of spherical involute, and combining our long term experience and specialty of twinscrew extruders,

Characteristics

1.There are involute cylindrical gears in the gearbox,which data and structure are optimally designed by the computer.

2.The gears are made of top-quality high-strength low carbon alloy steel after carbon penetrating,quench and teeth grinding.It has high hardness on teeth surface.large bearing ability,small noise,smooth operation and high driving efficiency.

3.The material of the distribution box is nodular graphite casting iron and the gears have high-strength ground teeth,in which snake-shaped cooling water pipes are distributed.

4.The maximum input speed of the gearbox is normally not larger than 1500 rpm.

5.The temperature in work environment is -10-45,when temperature is lower than 0,the lubricant oil should be preheated to +10 before starting.

Technical parameters

Application

1. The input rotation of prime mover shall be ≤1500rpm

2. The peripheral speed of gear drive shall be ≤20m/s

3. The working ambient temperature shall be within -40~45°C.Preheat the lubrication oil to above 0°C when the ambient temperature is below 0°C. Rotation is available both forwards and backwards. However, the high speed shaft of some types of reducers has a single way oil pump directing as defaulted to the output shaft which rotates clockwise.

Housing Case & Gears

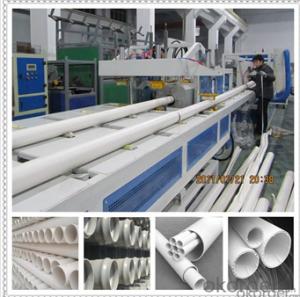

finished product

FAQ

1. Q: How about CNBM?

R: CNBM is a state-owned company in China. Our firm is composed of a strong team which has substantial experience in R&D, manufacture, technique and service, and has specialized in extruder industry for ten years, leading screw barrel manufacturer in China.

2. Q: What's CNBM capacity?

R: Our company is in strict accordance with CE and ISO9001 quality certification system. there are over 200 models of extruders and spare parts.

3. Q: What's the delivery time?

R: For regular size, we have finished stock and semi-finished stock, 2 weeks max are enough for customized, normally 3~4 weeks.

4. Q: Where is CNBM factory and how to reach there?

R: At xinqu, Wuxi, Jiangsu Province. If you want to visit us, we can pick you up in the airpor or train station.

5. Q: How to contact with us?

R: Plz reply to me directly if you have any question.

- Q: What are the machinery needed for plastic processing?

- In the case of an extruder, there are three kinds of resistance to overcome: the friction between the solid particles (feed) on the cylinder wall and the friction between them when the screw rotates several times (feed zone)

- Q: Plastic products manufacturing machinery parts company which?

- Shandong Changle Oriental machinery factory, plastic packaging machinery, parts, plastic machinery

Send your message to us

Worm Gear Reducer For Extruder Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 40 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches