Wood Plastic Composite Decking with SGS and CE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

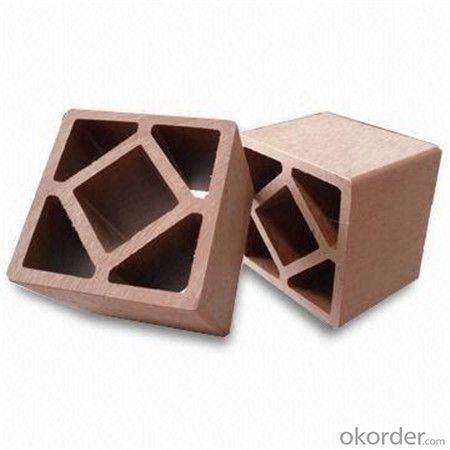

Structure of Wood Plastic Composite Decking

| 1.thickness: | 20mm,21mm,22mm,23mm,25mm, More items for your option |

| 2.width: | 140mm,150mmmm |

| 3.Length: | 2, 2.2,3,4...5.8 |

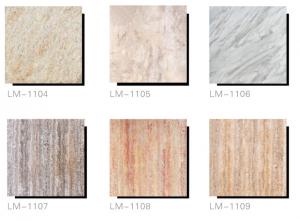

| 4.Color: | Black, Brown, Redbrown, teakwood, redwood, red, yellow. |

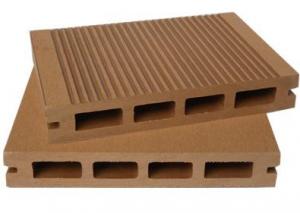

| 5.Surface: | Smooth, Brushed, Wood Grain & Sanded |

| 6.Component: | 30% HDPE+ 60% Bamboo Fibers +10% Chemical Additives |

| 7.Applications: | Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground. |

| 8.Packing | PE Film + WPC Pallet (length of 0-3m) |

| 9.Certificate | CE/ISO, ASTM, Fire Resistant, Anti UV, Anti Slip |

Main Features of Wood Plastic Composite Decking

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

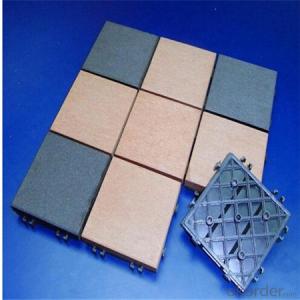

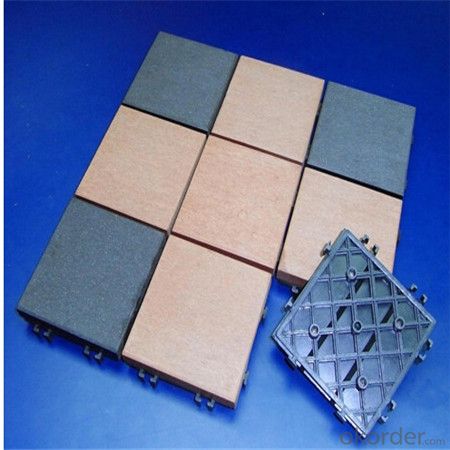

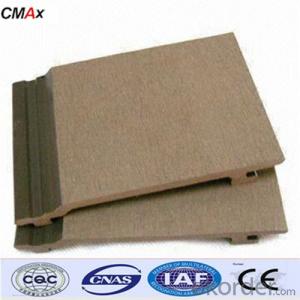

Picture show of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

Name | Wood Plastic Composite Decking |

Size | W*H=145*30 mm, can be customized |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

FAQ of Wood Plastic Composite Decking

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: My landlord in the balcony painted a thick paint, more than two months later, the smell is still very large, in order to health, and the landlord to negotiate, they agreed to remove the paint layer, but to keep the corner part. Now two days to remove the paint layer, but the smell is bigger. Now I want to purchase the floor, then at the boundary with plastic tape sticking. Do not know whether it can isolate formaldehyde, etc....

- No, because the formaldehyde volatilization is slightly less than the density of gas, air, volatile gas, have good air tightness of floor leather or plastic material, the gas will be volatile and will be hampered by spreading to other direction can be volatile, after all, floor leather and plastic is not closed, on the floor on the floor or other plastic material will have a certain gap, but the floor leather and plastic can be obviously reduced formaldehyde volatilization.

- Q: What is the plastic floor and what is the compound floor?

- As for the floor resistance to cigarette burning, there are national standards.

- Q: PVC floor, plastic floor, roll floor, floor leather, the difference between glue

- PVC floorIs a kind of new light ground decoration materials, also known as the "light body material, is widely used, such as families, hospitals, schools, factories, office buildings, public places, supermarkets, commercial, stadiums and other places.

- Q: Classroom platform shop plastic floor with no need to do self leveling?

- The floor is made of civil leather, paper and leather, the life of 1 to 2 years, not fireproof material, the price of 5 yuan to 15 yuan of 1 square meters, while the PVC floor is pure engineering material and plastic floor, PVC, life of 6 to 20 years, fire prevention materials,

- Q: With this plastic floor mat bed can not? Will not have any impact on people

- This floor is not allowed to use!! The utility model relates to a plastic floor leather, which belongs to the soft floor, which is made of polyvinyl chloride resin as the main raw material, and is added with appropriate auxiliary agent. Plastic floor leather, although difficult to burn, self extinguishing, but at high temperatures, will decompose harmful gases, excessive inhalation, suffocating. Floor leather containing lead compounds, in the use of the process, with the floor leather wear, lead content continues to spread, the formation of lead dust in the air, easy access to infants and young children

- Q: What is the name of the plastic floor on the supermarket, where is it?

- Buy plastic floor is a choice of material, how to install the plastic floor, plastic floor price, how much money the plastic floor, Shanghai plastic flooring, plastic flooring manufacturers, professional plastic floor, Fuzhou plastic floor, plastic floor thickness, plastic floor of environmental protection, Hangzhou plastic floor, size of plastic flooring, plastic flooring specifications, plastic floor how much money Nanjing Hefei Yiping, plastic floor, plastic floor

- Q: Is it the heat of the plastic sheeting does not affect it? Do you really have a moisture-proof effect?

- General is a thin layer of foam board, from the role of moisture.

- Q: Home decoration with plastic floor, please? What are its strengths and weaknesses?

- Plastic floor has many advantages,:Elastic, comfortable, can give people a warm feeling; 2 surface in UV processing, pollution resistant, easy to clean; 3 green environmental protection, does not contain formaldehyde, inhibit the growth of bacteria; 4 case of water stains, good skid resistance,

- Q: PVC plastic floor glue thickness can be used for welding

- Coil and sheet, so there are two kinds of glue:

- Q: Ijiali will be on the floor of the kind of plastic that is connected to a piece of letters, animal patterns, such as the name of what ah

- The ground cushion treasure is a new type of light plate which is extruded by polystyrene resin and other additives. The utility model has a continuous uniform and dense surface layer and a closed cell structure, and the wall of the honeycomb structure has the same thickness.

Send your message to us

Wood Plastic Composite Decking with SGS and CE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords