Extruded Plastic Composite Decking with SGS and CE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

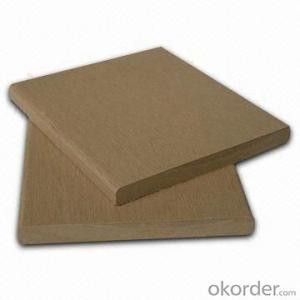

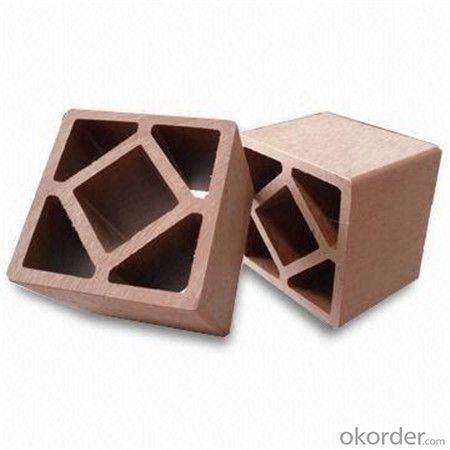

Structure of Extruded Plastic Composite Decking

| 1.thickness: | 20mm,21mm,22mm,23mm,25mm, More items for your option |

| 2.width: | 140mm,150mmmm |

| 3.Length: | 2, 2.2,3,4...5.8 |

| 4.Color: | Black, Brown, Redbrown, teakwood, redwood, red, yellow. |

| 5.Surface: | Smooth, Brushed, Wood Grain & Sanded |

| 6.Component: | 30% HDPE+ 60% Bamboo Fibers +10% Chemical Additives |

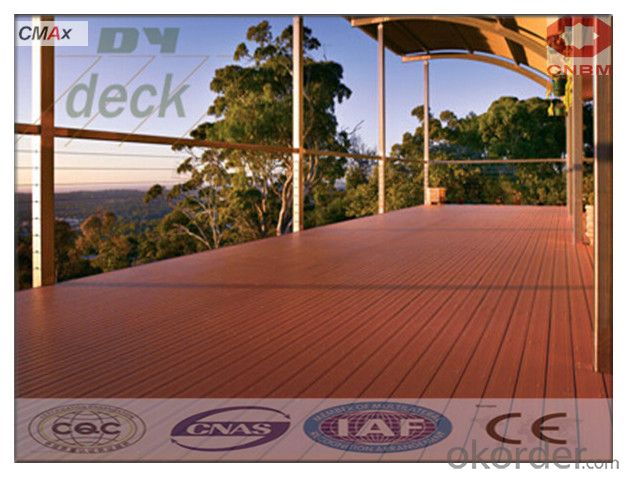

| 7.Applications: | Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground. |

| 8.Packing | PE Film + WPC Pallet (length of 0-3m) |

| 9.Certificate | CE/ISO, ASTM, Fire Resistant, Anti UV, Anti Slip |

Main Features of Extruded Plastic Composite Decking

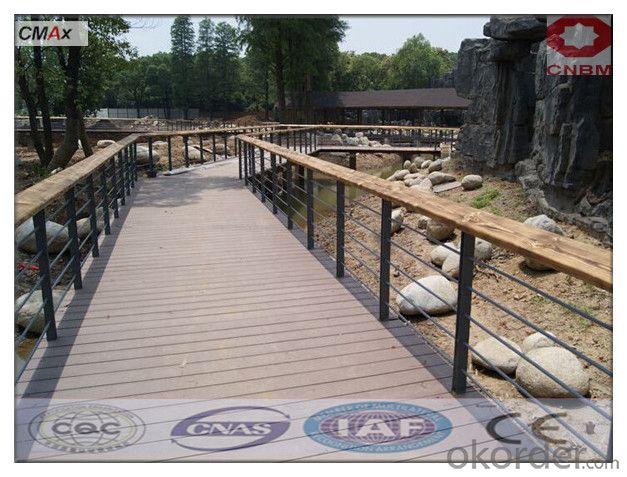

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

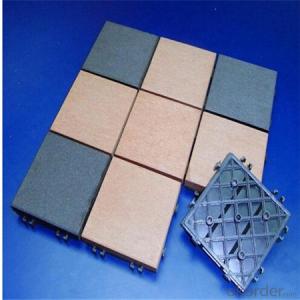

Picture show of Extruded Plastic Composite Decking

Specification of Extruded Plastic Composite Decking

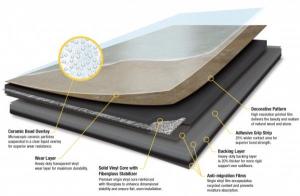

Name | Extruded Plastic Composite Decking |

Size | W*H=145*30 mm, can be customized |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

FAQ of Extruded Plastic Composite Decking

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: Board PVC plastic floor plastic toxic

- Board PVC plastic floor is a green plastic decoration materials, no poison.

- Q: How to tear off the plastic film on the floor tiles

- To be transferred to the factory, in order to prevent damage to the floor during the renovation, in the brick surface have done a deal with the pollution, the general polishing brick made of anti fouling wax

- Q: What a pig with plastic floor to sell, how much money

- Farmers - Sheng - Le plastic drain board it is unique1: the temperature difference between day and night plastic is smaller than iron, is conducive to the health of piglets and sows, so as to avoid temperature and cold or scald.2: the surface of the manure board matte treatment, increase the contact surface, improve friction, so as to prevent the fall of injured animals.3: washing machine can be used to wash the high-pressure water gun, made into a day without cracks, should not be hidden dirt.4: the company's production of plastic drain board made of pure raw materials, white shiny surface, high quality, durable.5: the plastic plate is suitable for conservation, piglets in farrowing crate bed, bed, sheep dog cage Quanshe dung floor

- Q: Worried about a long time, plastic aging, small ironExpose the floor.

- Very good, maple furniture, material is also good! The design is a combination of Chinese and western, so like a modern American, Jane, pastoral, Mediterranean, Chinese, Southeast Asian style decoration can not pick collocation, decoration! Do the old American color is also very beautiful, not easily outdated! And its furniture is also very focused on the functional and user-friendly, very practical.

- Q: What is the difference between PVC plastic floor and graphite plastic floor

- The PVC anti-static floor is PVC resin as the main body, there are PVC particles wrapped in the surface of carbon fiber, vulcanized, molded from the semi rigid sheet, the appearance of carbon fiber network pattern. It is a permanent antistatic body is homogeneous, is from the bottom to the pattern material is the same, the floor if the surface being burned or cut off, can use the grinder to waxing is as good as new. The anti-static floor has a strict limit on the resistance value. Common resistance in 10 of the 6 to the 9 of the floor between the 10 is called anti-static floor, resistance in the 10 to the 10 of the 6 party called the conductive floor. Anti static floor is mainly used in the room, special wards, fine workshop, and some of the special requirements of the static space.

- Q: You master the family, to help me, I do not care about the color of plastic bags on the floor tiles, and how to rub are not wiped out, please help me master, I will add the score

- 1, ceramic tiles can be used daily cleaning detergent, soap and other cleaning.2, with a small amount of soap and water mixed with turpentine oil, cleaning tiles can make the tiles more luster.

- Q: Heard that there is a special plastic floor nursery? What are the benefits

- Kindergarten special plastic floor is very popular now, the benefits are: 1, the green environmental protection: the kindergarten plastic floor 100% new environmental protection material: PVC, does not contain formaldehyde, does not contain asbestos, lead, mercury and other harmful heavy metal filler, fully meet the needs of children of green space.

- Q: The advantages of plastic floor tile

- Super slip: wear-resistant layer PVC plastic floor surface has a special anti-skid, and compared with common ground material, PVC floor (plastic floor) in the sticky water situations. More astringent, but not easy to slide into the water, which is more astringent. 6, fire retardant: PVC plastic floor fire index up to B1 level, B1 level that is very good fire performance, second only to stone. 7, waterproof: PVC plastic floor is the main component of vinyl resin, and water affinity, so its nature is not afraid of the water, as long as not long soak would not be damaged; and not because of high humidity and mildew

- Q: How to deal with the plastic foam on the floor?

- Some special traces can be cleaned immediately or with a mild detergent or warm water on the market, do not use a large amount of water to clean the floor. Avoid containing thick objects falling on the floor, such as chewing gum, otherwise it is difficult to clean up. Do not need wax and paint, do not use sandpaper polishing. Because laminate flooring surface has been relatively smooth, brightness is also relatively good. Reduce water loss.

- Q: Is plastic floor glue toxic? Thank you

- Sports plastic floor (non-toxic, no harm to the human body): mainly used for buses, trains (trains and high-speed rail), stadiums, large public places (passenger stations, high-speed rail station)

Send your message to us

Extruded Plastic Composite Decking with SGS and CE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords