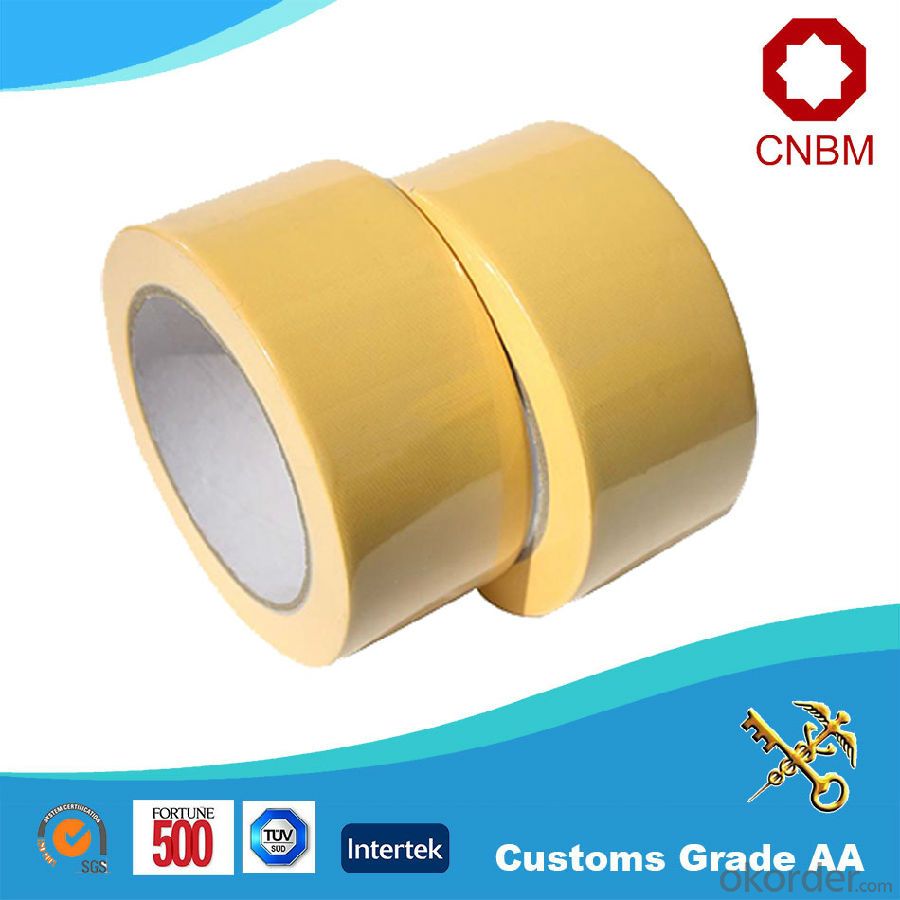

Clear Packaging Tape with PVC Film and Natural Rubber Wire Harness Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

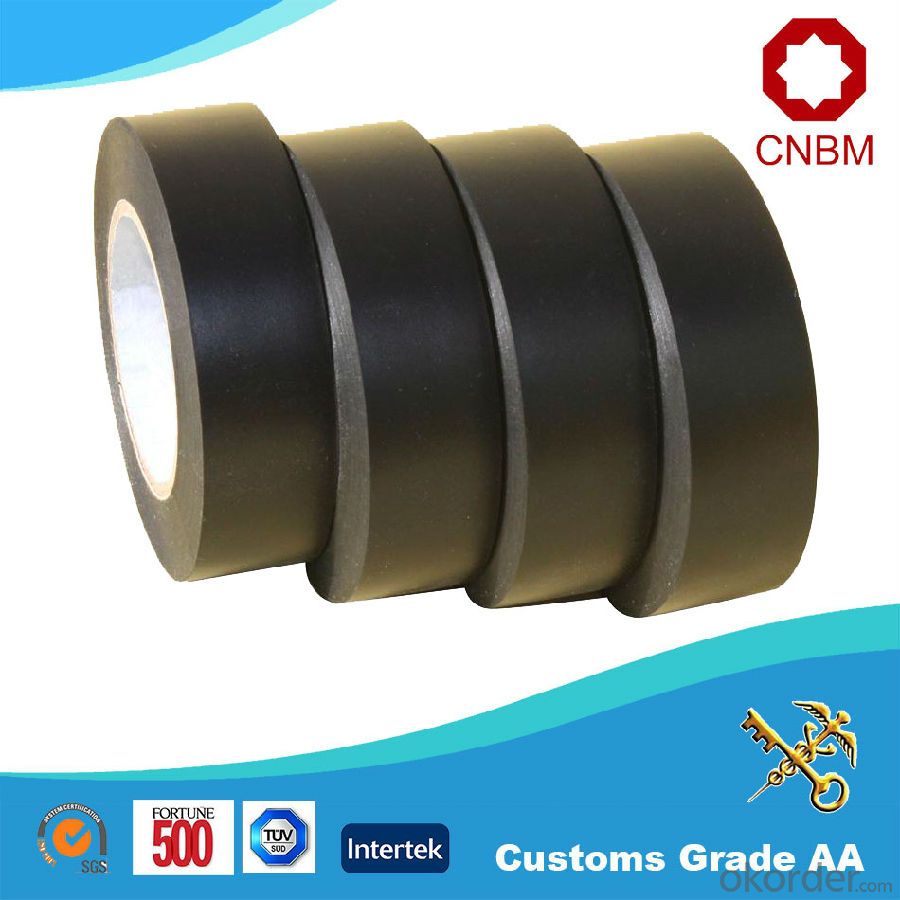

Wire Harness Tape with PVC Film and Natural Rubber

1. Structure of Wire Harness Tape Description

Wire Harness Tape is of PVC film as the carrier, coating with natural rubber. Wire Harness Tape: widely used as permanent wrapping on cables and wiring harnesses for automobile.

2. Main Features of the Wire Harness Tape

Burning-resistance

Non-corrosive adhesive

Self extinguishing

Water resistant and moisture resistant

Safety and environmental friendly

Resistant to cold temperature

3. Wire Harness Tape Images

4. Wire Harness Tape Specification

Item No. | Thickness (micron) | Adhesion to steel (N/cm) | Tensile Strength (N/cm) | Elogation (%) | Teperature Resistance (DC) | Flame Resistance (S) |

PW-11 | 110 | 1.2 | 15 | 150 | 80 | <2< span=""> |

PW-12 | 120 | 1.2 | 16 | 150 | 80 | <2< span=""> |

PW-13 | 120 | 1.2 | 20 | 180 | 80 | <2< span=""> |

PW-15 | 120 | 1.2 | 25 | 200 | 80 | <2< span=""> |

5. FAQ

Q1. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Q2. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

Q3. Packing and Delivery

Packaging Details: 120 brolls per carton(39*27*30) according to different size

Delivery Detail: 7 to30 days according to different quantity

- Q: How does the tape used for packing the finished product in the workshop be accounted for?

- Adhesive tape for packaging of finished goods in workshopBorrow: recycled material - packagingTaxes payable - VAT payable - VAT

- Q: Does packaging tape come in different lengths for convenience?

- Yes, packaging tape does come in different lengths for convenience.

- Q: Does packaging tape come in different widths for different applications?

- Packaging tape indeed comes in a variety of widths to suit different purposes. You can find packaging tape in a range of widths, starting from as little as 0.75 inches and going up to 3 inches or even wider. The width you choose depends on the specific task at hand and the size of the package you are sealing. When dealing with lighter packages or sealing small boxes or envelopes, it is common to opt for narrower widths. Conversely, wider tape is frequently used when dealing with heavy-duty or larger boxes that require added strength and security. With the availability of different widths, users can easily select the most suitable tape size based on their unique packaging requirements.

- Q: Can packaging tape be used for sealing metal boxes?

- Yes, packaging tape can be used for sealing metal boxes. Packaging tape is designed to provide a secure and durable seal on various surfaces, including metal. It offers a strong adhesive that can effectively stick to metal surfaces, ensuring that the box remains sealed during transportation or storage. However, it is important to choose a packaging tape that is suitable for heavy-duty applications and can withstand the weight and pressure that may be exerted on the metal box. Additionally, it is recommended to clean the metal surface before applying the tape to ensure proper adhesion.

- Q: Are there any specific instructions for reusing packaging tape?

- There exist specific instructions for reusing packaging tape. Here are several guidelines to adhere to: 1. Exercise caution when removing the tape from the package: Upon receiving a package, make an effort to delicately remove the tape in order to prevent tearing or damaging it. 2. Cleanse the tape: Should the tape possess any dirt, dust, or residue, it can be cleansed by gently wiping it with a moist cloth. Allow it to fully dry before reutilizing. 3. Assess the adhesive strength: Before reusing the tape, verify if the adhesive remains sufficiently strong to securely hold. If it has lost its stickiness or sustained damage, it is advisable to discard it and employ a fresh piece of tape. 4. Properly store the tape: To maintain the tape's quality for future use, store it in a cool, dry area away from direct sunlight. This will assist in preventing it from drying out or becoming brittle. 5. Utilize it for light to medium-duty tasks: Reused packaging tape may not possess the same strength as new tape, therefore it is most suitable for lighter to moderately demanding tasks. Avoid utilizing it for heavy items or applications necessitating a stronger adhesive. Bear in mind, while reusing packaging tape constitutes an excellent approach to waste reduction, it is crucial to prioritize functionality and security. If the tape becomes damaged or loses its adhesive strength, it is advisable to replace it with a new piece to ensure proper sealing of your package.

- Q: How does packaging tape differ from masking tape?

- Packaging tape differs from masking tape primarily in terms of their intended uses and adhesive properties. Packaging tape is specifically designed for sealing boxes and packages, providing a strong and durable bond that can withstand shipping and handling. It is usually made of a strong material like polypropylene and has a strong adhesive that sticks well to various surfaces, including cardboard and plastic. On the other hand, masking tape is designed for temporary applications like painting and crafting. It has a less aggressive adhesive that allows for easy removal without leaving residue or damaging surfaces. Masking tape is typically made of paper and is not as strong as packaging tape, making it unsuitable for heavy-duty tasks like sealing boxes for shipping.

- Q: Does packaging tape come in different allergen-free options?

- Indeed, various allergen-free alternatives exist for packaging tape. Numerous manufacturers provide packaging tape that is explicitly formulated to be hypoallergenic, devoid of typical allergens like latex, gluten, and other potential irritants. These options without allergens prove especially advantageous for individuals with sensitive skin or allergies. It is highly advisable to thoroughly peruse the product labels or descriptions to guarantee that the packaging tape aligns with your precise allergen-free needs.

- Q: Can packaging tape be used for securing shipments during transit?

- Yes, packaging tape can definitely be used for securing shipments during transit. Packaging tape is specifically designed to provide a strong and reliable seal for packages, ensuring that they remain intact and protected during transportation. It is commonly used for sealing cardboard boxes, securing bubble wrap or other protective materials around items, and reinforcing the closure of packages. Packaging tape is durable, easy to use, and provides a secure bond, making it an ideal choice for securing shipments during transit.

- Q: Can packaging tape be used for sealing foam?

- Sealing foam can be achieved by using packaging tape. While packaging tape is commonly used for sealing boxes and packages, it can also be effectively used to seal foam. To create a tight seal, it is important to make sure that the tape is securely adhered to the foam surface by applying pressure after it has been applied. It is advisable to use a tape specifically designed for sealing foam, as these tapes usually have stronger adhesive properties and are more resistant to temperature changes and moisture. In conclusion, packaging tape can be a convenient and effective choice for sealing foam.

- Q: General adhesive tape is a taste, the size of the taste depends on the formula of glue, low molecular weight content, taste will be larger, once adhesive tape, it has a very small taste tape, we have been using.

- Slitting machine pressing wheel with a belt, in cutting the air away, if you want to good effect, the sub machine pressing wheel to large and soft (preferably with 20CM diameter), so the effect will be much better than disadvantage is cut cut the tape surface appearance;

Send your message to us

Clear Packaging Tape with PVC Film and Natural Rubber Wire Harness Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords