AC Tape and Packaging Ltd - Wire Harness Tape PVC Red Yellow Blue Green

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wire Harness Tape PVC Red Yellow Blue Green

1. Structure of Wire Harness Tape Description

Wire Harness Tape is of PVC film as the carrier, coating with natural rubber. Wire Harness Tape: widely used as permanent wrapping on cables and wiring harnesses for automobile.

2. Main Features of the Wire Harness Tape

Flame resistance

Self extinguishing

Non-corrosive adhesive

Moisture resistant

Resistant to cold temperature

Environmental friendly

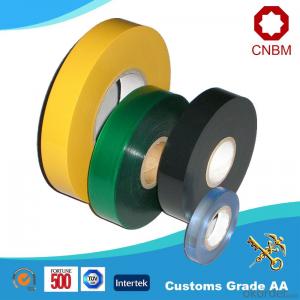

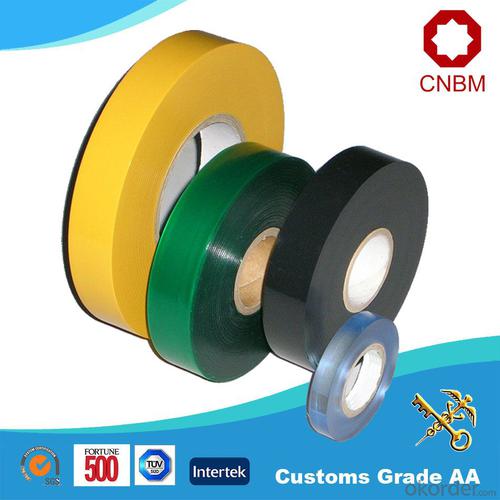

3. Wire Harness Tape Images

4. Wire Harness Tape Specification

Item No. | Thickness (micron) | Adhesion to steel (N/cm) | Tensile Strength (N/cm) | Elogation (%) | Teperature Resistance (DC) | Flame Resistance (S) |

PW-11 | 110 | 1.2 | 15 | 150 | 80 | <2< span=""> |

PW-12 | 120 | 1.2 | 16 | 150 | 80 | <2< span=""> |

PW-13 | 120 | 1.2 | 20 | 180 | 80 | <2< span=""> |

PW-15 | 120 | 1.2 | 25 | 200 | 80 | <2< span=""> |

5. FAQ

Q1. What can we do for you?

Professional consultation on your local market

Custom-made advices for your need

Satisfactory sales service

Free samples

Your inquiry will be replied within 12 hours.

Well-trained & experienced sales representative are ready to answer you.

Q3. Packing and Payment

Payment: T/T,L/C,Western Union,Paypal, Aliexpress. etc.

Delivery Detail: 7 to30 days according to different quantity

Q3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can packaging tape be used for sealing plastic lunch boxes?

- Yes, packaging tape can be used for sealing plastic lunch boxes.

- Q: Is packaging tape safe for use on children's toys or products?

- No, packaging tape is not safe for use on children's toys or products. It is not designed or tested to meet the safety standards required for products intended for children. It is important to use child-safe materials and adhere to safety guidelines when it comes to products that will be used by children.

- Q: Does packaging tape come in different allergen-free options?

- Indeed, various allergen-free alternatives exist for packaging tape. Numerous manufacturers provide packaging tape that is explicitly formulated to be hypoallergenic, devoid of typical allergens like latex, gluten, and other potential irritants. These options without allergens prove especially advantageous for individuals with sensitive skin or allergies. It is highly advisable to thoroughly peruse the product labels or descriptions to guarantee that the packaging tape aligns with your precise allergen-free needs.

- Q: Can packaging tape be used for sealing arts and crafts materials?

- Yes, packaging tape can be used for sealing arts and crafts materials. It provides a strong and secure bond, making it suitable for various types of materials such as paper, cardboard, and plastic. However, it is important to consider the aesthetics and longevity of the tape, as there may be more specialized options available for specific art and craft projects.

- Q: Can packaging tape be used for securing shipments during transit?

- Yes, packaging tape is commonly used for securing shipments during transit. It provides a strong and reliable seal that helps keep packages intact, preventing them from opening or getting damaged during transportation.

- Q: Is packaging tape safe to use on stainless steel?

- Yes, packaging tape is generally safe to use on stainless steel as it does not usually cause any damage or leave adhesive residue. However, it is always recommended to test a small, inconspicuous area first to ensure there are no adverse reactions or issues with the specific type of tape being used.

- Q: Can packaging tape be used for sealing packages with irregular shapes?

- Indeed, when it comes to sealing packages with irregular shapes, packaging tape comes in handy. Its flexibility and adhesive nature make it perfect for securing packages of different sizes and contours. Thanks to its strong adhesive properties, packaging tape can adhere to various surfaces, even those that are uneven or irregular, ensuring that the package remains tightly sealed during transportation. Moreover, packaging tape is known for its durability and tear-resistance, providing an added layer of protection for the package. Consequently, whether the package boasts an irregular shape or not, packaging tape proves to be a dependable and efficient choice for sealing it securely.

- Q: Can packaging tape be used for sealing cardboard boxes?

- Yes, packaging tape is commonly used for sealing cardboard boxes as it provides a strong and secure bond.

- Q: Can packaging tape be used for sealing plastic storage baskets?

- Yes, packaging tape can be used for sealing plastic storage baskets. Packaging tape is designed to be strong and adhesive, making it suitable for securing and sealing various types of materials, including plastic. By using packaging tape, you can effectively seal the openings or seams of plastic storage baskets, keeping the contents secure and protected. However, it is important to note that the longevity and effectiveness of the seal may depend on the quality and durability of the specific packaging tape used. Additionally, it is recommended to clean and dry the surface of the plastic storage baskets before applying the tape to ensure proper adhesion.

- Q: Can packaging tape be used for sealing plastic toys?

- Yes, packaging tape can be used for sealing plastic toys. It provides a strong adhesive bond and helps keep the toy's packaging secure.

Send your message to us

AC Tape and Packaging Ltd - Wire Harness Tape PVC Red Yellow Blue Green

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords