Wind-Solar Hybrid LED Street Light with 60W Lamp

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 units / month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The wind-solar hybrid LED street light system including Maglev vertical axis wind turbine, wind-solar hybrid intelligent controller, 60W LED lamp, Solar Panel, Battery with Pole. Each parts detail introduce as below:

Maglev vertical axis wind turbine

maglev technology personnel was our company integrating appearance design, practical design, mechanical, electrical engineering, power, wind tunnel test of atmospheric air, maglev technology, computer simulation fraction disciplines such as integrated, using maglev technology theory, without any mechanical friction in motor under the condition of wind loads, in turn, make fan motor startup, high grade 1 wind power generation, smooth operation

Wind-Solar hybrid intelligent controller

The intelligent controller has three main functions:

Prevent battery overcharge and over discharge

Change AC into DC

Can be set time, RPM and light control with time control to street light

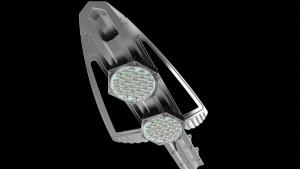

LED Lamp

Self-research and design, use CREE brand chip, high-strength tempered glass with better light transmission and UV resistance. Power efficiency was higher than 93%, 50000 hours life span with intelligent dimming function.

Solar Panel

Generally we use MONO silicon solar panel that it transform efficiency can be get 18% above

Battery

Used lead-acid or GEL batteries, usage time between 3 to 5 years. Wanted more battery usage time please use lithium iron phosphate battery

Light Pole

Used Q235 high-quality steel, the thickness of up to 9mm around, and after DACROMET technical treatment, can be anti-rust anti-acid, alkali

Installation:

• Easy Installation: System can be assembled within one hour

• No welding

• Single or multiple unit connection for bigger power production

• Easy connection with PV systems

3,Design:

• Gearless design: no need to replace worn-out or broken gear

• Brushless: motor brushes making high failure items results in regular replacements

• Bearing-free design: no need to lubricate or to replace worn-out bearings

• Magnetic levitation design: reduces rotational resistance to enhance power generation as well as prolong the turbine life.

• No yaw or furling mechanism required: allows for peak power output at any wind speed

• No cogging torque for cutting-in at low wind speed

• Direct-drive: Extends product life

• Blades can start rotating at very low wind velocity of 2.2 mph (1 m/s)

• Space-saving, aerodynamic airframe

• Heavy duty and industrial level construction

Wind Solar Hybrid Street Light System With Doulbe LED Lamps

Application

The wind solar hybrid system can be applied to many places,

Street lighting

High way lighting

Park lighting

Park lot lighting

Square lighting

Landscape lighting

Tourist site lighting

Specification

Rated power | Approx. 300Wh at 13 m/s (26 mph) |

Swept Area | 0.8 m2 |

Height / Diameter | 1.23/1.09 m |

Weight | 27 kg |

Shipping Dimensions | 1160 x 520 x 790 mm 56 kg |

Startup Wind Speed | 1 m/s (2.6 mph) |

Voltage | 12, and 24 V AC |

Turbine Controller | Smart Wind $ solar hybrid controller |

Body | Permanent mold cast aluminum |

Blades | (7) Injection-molded aluminum |

Alternator | Permanent maglev generator |

Overspeed Protection | 3 phases short-circuit braking control |

Survival Wind Speed | 65m/s |

Mount | Inner diameter 80MM 140mm outer diameter |

Wind Speed Operating Range | 1-15 m/s (8-49 mph) |

Optimum Wind Speed Range (RPM) | 8-10 m/s ( 750-800RPM) |

Why to choose TYPMAR wind turbine ?

The CXF series of maglev wind turbines undergoes a continuous improvement process, which incorporates exterior design, utility design, electrical engineering, dynamic engineering, power mechanics, aviation air engineering, wind tunnel testing, lightening protection, computer simulation techniques and other multiple subjects to have the following features:

Magnetic levitation technology

Independent of the direction of the wind

Startup at low wind speed of 1m/s

Higher efficiency compared to traditional HAWT

Works even in turbulence

Visually pleasing appearance

Turbine construction is resistant to gale 60m/s (132MPH)

Robustness and adaptation to all possible environmental conditions thanks to material of aluminum alloy or stainless steel

Design life: at least 20 years

Noise: Tested by China National Machinery Quality Inspection Centre at 12m/s: <40db

HAWT AND MVAWT | ||

Item | Horizontal axis (HAWT) | Vertical axis (EML) |

Start wind speed | High(≥3m/s) | Low(1m/s) |

Wind conditions required | Require stable wind direction | Any wind direction |

Encountered turbulence | Reduce the efficiency | Efficiency is not affected |

Power stability | Change by wind direction | Without any wind effect |

Noise | Large(45 decibels or more) | Low noisy (because there is no mechanical friction) |

Product appearance | Normal | Beautiful |

Installation height | High(need to avoid the terrain turbulence) | Low(not afraid of turbulence) |

Installation location | Just in open area like suburb | Any location |

Generator material | Plastic or composite | metal |

Structure strength | Poor (easy to broken) | High(double strengthen arm) |

Resistance of wind speed | Poor(about 40 m/s) | High |

- Q: Recently went out to do the test, do not know the difference between the two tests

- Preventive testing is to test or test equipment periodically and regularly. For example, once a month, 3 months or a few times a year of preventive testing or testing, to exclude the existence of hidden dangers...

- Q: Is the GIS in the electric power high voltage switch cabinet

- GIS is a shorthand for two conceptsThe 1 is the geographic information system.2 refers to the (GAS INSULATED SWITCHGEAR) gas insulated fully enclosed combination of electrical appliances, closed inside the main circuit breaker, isolation switch, grounding switch, bus, lightning arrester, etc.. Many power plants, substations, switching stations are made of GIS, so that the small footprint, or maintenance. With the high voltage switch cabinet or not.

- Q: Under the same voltage level, the rated voltage of the equipment is not exactly the same

- For different electric appliances, rated voltage may be different, commonly used for 220V, 280V, and some appliances used in not rated voltage can still work, but not up to the ideal working condition, rated voltage and the voltage at both ends of the electric appliance has nothing to do with.

- Q: Electrical equipment classification

- Electric power system in a lot of power equipment, according to their role in the operation of different, usually divided into electrical equipment and electrical equipment two times. Directly involved in the production, transformation, transmission, distribution and consumption of electrical equipment called electrical equipment

- Q: On the safety hazards of electric equipment safety

- 3 where in the overhead power line protection zone new, reconstruction or expansion of the building, must go to the power supply department for the approval of the relevant procedures for the safety of power facilities construction. It is forbidden to borrow, dig fish ponds, pile up or dump harmful chemicals in the power line protection zones.4 where the demolition, the power line protection zones of overweight, lifting, drilling, piling, scaffolding and other construction work, it shall be permitted by the power supply departments, take appropriate safety measures, and can work in the power supply department under the supervision of professional staff.

- Q: Power test equipment sales to find power supply company which departments? Which departments of the power supply company will use the power test equipment?

- What kind of power test equipment are you in charge of? Our unit is divided into the experimental class and the automation experiment class

- Q: The difference between electric load and power supply capacity

- Power consumption / power consumption of electric equipment used for electric power load.Power supply capacity of the power supply system, generally refers to the user step-down transformer capacity, such as how many kva.

- Q: Hello, I would like to ask what are the main rotating equipment in the power system? What is a rotating device?

- The transformer is non rotating equipment. There are a lot of rotating equipment in power plants, such as fans, fans and so on, of course, the most important is the generator

- Q: Withstand voltage test, power equipment insulation unqualified reasons?

- Without proper consideration of the atmospheric conditions that affect the insulation characteristics. Because of the pressure, temperature and humidity have a certain impact on the spark discharge voltage and breakdown voltage, without considering these factors may lead to equipment failure.

- Q: The two devices of the power system have those

- 4, relay protection and automatic devices, such as relays, automatic devices, used to monitor the operation of a system, rapid response to abnormal and accident, and then acts on the circuit breaker, protection control.5, DC power supply equipment, such as storage batteries, DC generators, silicon rectifier, etc., to provide control and protection of DC power supply and DC load and emergency lighting, etc..6, high frequency wave blocking device.7, since the cast device.

Send your message to us

Wind-Solar Hybrid LED Street Light with 60W Lamp

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 units / month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords