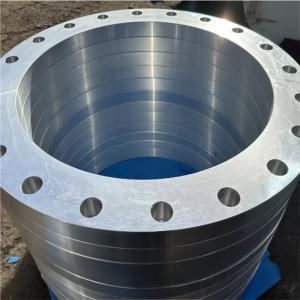

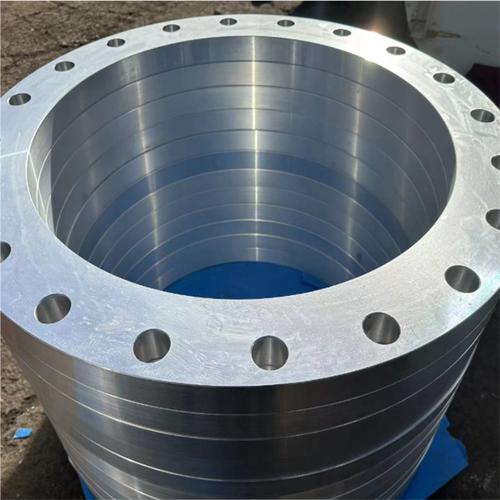

Large diameter stainless steel welded flange

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

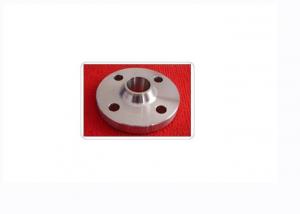

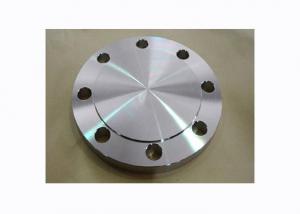

You Might Also Like

Specification

Large diameter stainless steel welded flange

A flange is a component that connects shafts to each other and is used for connecting pipe ends; It is also used for flanges on equipment imports and exports, used for connecting two devices.

Connection method

Flange connection is the process of fixing two pipes, fittings, or equipment onto a flange plate, adding flange pads between the two flanges, and fastening them together with bolts to complete the connection.

The main application scenarios of flanges

1. Industrial pipelines

In industries such as petroleum, chemical, pharmaceutical, and food, flanges are often used to connect equipment such as pipelines, heat exchangers, and storage tanks. The advantage of flanges is that their connection method is firm and reliable, and they are easy to maintain and replace.

2. Ships and Ocean Engineering

They can be used to connect pipeline systems of ships, as well as pipeline systems connecting offshore wind turbines and oil well platforms. These applications typically require flanges to have corrosion resistance and anti-corrosion properties.

3. Construction Engineering

In construction engineering, flanges are also used to connect the piping systems and HVAC systems inside buildings. In addition, flange connections between steel and concrete structures are also required on the exterior of some large buildings, such as high-rise buildings, bridges, etc.

4. Automotive and Mechanical Engineering

In automotive and mechanical engineering, flanges are commonly used to connect piping systems between different components, such as the connection between an engine and an exhaust pipe. Flanges can also be used to connect hydraulic systems and air systems.

Advantages of flanges

1. Tight connection: The flange connection is tight and will not loosen due to vibration or distortion, effectively ensuring the safety and reliability of the pipeline system.

2. Easy to disassemble: Flange connection is the process of connecting two parts with flange sealing gaskets, screws, etc., making it convenient for maintenance, replacement, and other operations without the need to disassemble the entire pipeline.

3. High adhesion: The flange connection and sealing are relatively tight, with high sealing and adhesion, and there will be no leakage, mixing or other problems, which can ensure the stability and safety of the pipeline system.

4. Strong adaptability: Flange connections are suitable for various specifications of pipelines and can meet the needs of various pipeline layouts, with a wide range of applications.

- Q: What is the material of plastic flange

- The plastic flange generally of iron or steel as matrix, and the inner and outer walls coated with high polymer materials.Internal and external coating materials are generally polyethylene (PE), crosslinked polyethylene (PEX), epoxy resin (EP) and so on.The plastic flange corrosion resistance, no exudation, no pollution, high strength, good pressure resistance, aging, embrittlement, to adapt to the harsh environment, long service life, is mainly used in petroleum chemical industry, electric power, light industry factory of the acid solution, alkali, salt solution and various chemical and water transport.

- Q: Where is the flange used in the pump?

- Flanges are used on pipes and valves that are connected to the pump. Generally, each pump inlet and outlet at least three flange and a two valve valve.

- Q: The back of a valve is sealed directly with a flange. What do they want to secure? I saw something called a double disk D219x6. What's this? If I were 150, how big would the pipe be?

- After the valve flange sealing plate is normally called flange blind plate, as they are sealed in the middle of things, generally have metal winding pad or Teflon pad. D219x6 (outside diameter * wall thickness) is the specification of the pipe. As to how big the 150 pipe is, this is the standard piece. When you go to the hardware store or the manufacturer to buy it, it is OK to tell him that it is DN150's flange.

- Q: Why do not use the first gasket and tighten the flange bolts, and then welding flange welding method for flange welding?

- Flanges produce large amounts of heat when they are welded, which will burn the gasket and deform easily under the influence of bolts and heat. The fear of harm in Wei Di apps

- Q: Why is the piece of iron between the two pipe flanges?

- This is called a flange gasket, which acts as a seal to prevent liquid from leaking through the flange joint.

- Q: What does "flange PL150-16RF" mean, PL RF? I know what 150-16 means

- 150 is the flange diameter 150MM meters, 16 is, 16 kilograms, namely 1.6MPa

- Q: Flange blind plate production and installation should be fixed what quota ah?

- Sets 6 volumes of industrial pipes "pipe *0.6""

- Q: DN125 valve with DN125 flange, right?

- It must be true, but it also depends on the engineering pressure and the requirements of the sealing surface

- Q: 76X6 seamless steel tubes with large flanges?

- DN65 to see the pressure of low pressure plate welding flange PL or SO hard flat high voltage WN butt welding is resistant to corrosion or if it can wear SO

- Q: What is a blind plate unit? Is it the same as the flange?

- This is not a problem, the same sealing surface matching flange can be said to be a pair, can also be said to be a piece of two, flange cover (blind plate), according to pieces that standard. Moreover, the names of some trades are different from those of different trades. According to the standards of their respective trades.

Send your message to us

Large diameter stainless steel welded flange

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches