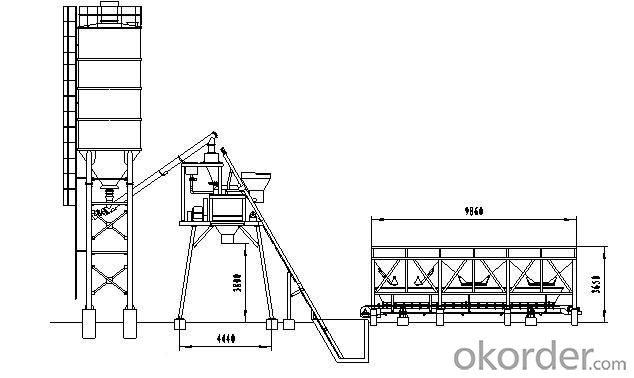

WCQ300G Stabilized Soil Mixing Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 2 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stabilized soil mixing plant is special mixing plant for achieving the continuous even mixing of a variety of stabilized road base materials with high batching accuracy (in accordance with the requirements of raw materials), it is widely used in the construction work for road, airport, dock and other construction projects.

Its components include an aggregate supply measuring system, powder supply measuring system, water supply system, mixing device, storage device and control system.

Our stabilized soil mixing plant uses a durable twin-shaft mixer for excellent performance and high efficiency, it can mix various kinds of materials (including cement) and make all types of stabilized soil, and its productivity is 300-600t/h;

The plant is compact and modular designed for easy installation and movement, and containerized transportation is optional;

Computerized control system and electronic weight system gives high degree of automation and batching accuracy, and the plant can be switched between manual operation and automatic operation.

PRODUCT DETAILS

![]() Modular Container Type Batching System

Modular Container Type Batching System

![]() The number of batching bins is determined by the requirements of our customers.

The number of batching bins is determined by the requirements of our customers.

![]() The device is easy to install and dismantle, enabling easy movement when relocate.

The device is easy to install and dismantle, enabling easy movement when relocate.

![]() The aggregate conveyor belt scale and mixture conveyor are pre-adjusted in order to save the installation time.

The aggregate conveyor belt scale and mixture conveyor are pre-adjusted in order to save the installation time.

![]() Mixing System

Mixing System

![]() The system has an advanced no-scale-board forced twin-shaft continuous mixer.

The system has an advanced no-scale-board forced twin-shaft continuous mixer.

![]() The specific discharging port on both sides and at bottom of mixer makes it convenient and easy to clean.

The specific discharging port on both sides and at bottom of mixer makes it convenient and easy to clean.

![]() The special wear-resistant alloy blades greatly increase its durability.

The special wear-resistant alloy blades greatly increase its durability.

![]() A lengthened mixing shaft and well-distributed mixing blades facilitate thorough and even mixing, eliminating the problem of material isolation.

A lengthened mixing shaft and well-distributed mixing blades facilitate thorough and even mixing, eliminating the problem of material isolation.

![]() Cement Storage, Supplying and Measuring System

Cement Storage, Supplying and Measuring System

![]() Cement Storage and supplying

Cement Storage and supplying

Customized configurations of cement silos are available. We can provide 50 ton, 80 ton, 100 ton and other sizes of cement silos according to your requirements. Single silo, double silo and multiple silos are also available. Based on silo configurations, the user can choose single measuring or separate measuring modes.

Besides, there are bagged cement conveying systems, bucket elevators and other accessories for our clients to choose. You special design requirements can also be satisfied.

The enlarged cement discharging port can prevent cement from arching, thus making the measurement more accurate. And pneumatic arch-broken devices are installed to ensure continuous and accurate measurement.

![]() Cement Measuring Device

Cement Measuring Device

The cement measuring device is made up of an overflow reamer and a measuring reamer.

The overflow reamer has a large charging port, which ensures continuity and stability of cement conveying. The overflowing structure of discharging port ensures that the material fall continuously and evenly, thus helping to make accurate measurements.

Measuring reamer adopts a suspended structure, and is not influenced by external conditions. Sensor, PLC, computer and frequency converter constitute a whole set of an efficient measuring control system. When certain parameters are calibrated, the control system can automatically carry out accurate measurements.

SPECIFICATION

Model | WCQ300G | |

Output(m3/h) | 300 | |

Mixer | Mixing Power (kW) | 2×22 |

Aggregate Size (mm) | ≤50 | |

Dosing Tank Volume (m3) | 4X9 | |

Belt Conveyor Conveying Capacity (ton/h) | 400 | |

Weighing Range and Accuracy | Aggregate (Kg) | ±2% |

Cement (Kg) | ±1% | |

Water (Kg) | -1%~+2% | |

Total Power (kW) | 106 | |

Discharge Height (m) | 3.6 | |

- Q: i know not to eat much when trying to decrease the size of your tummy, so don't bother mentioning it.

- 1. You have to eat ur three basic meals a day, even when trying to lose weight don't starve yourself. Its all sbout your portion control. 2. Swimming is fun and I've lost around 3 pounds in June just frim swimming for 30 min. every day. It really works.

- Q: This book was published in 1927 by John Deere Corp., the first of a series for use in schools. It is now mainly of interest to collectors of antique farm machinery.

- Research what the book is worth and set the price at whatever percentage of that you feel comfortable with.

- Q: Which prescription drug goes best with Jack Daniels when operating heavy machinery?

- Morphine

- Q: The Tom Smith Corporation has the following items: Cash, $5,000; Machinery, $50,000; Building, $150,000; Note payable bank, $10,000; Savings, $10,000; Long term debt, $50,000; Accounts payable, $30,000; Taxes payable, $5,000; Accounts receivable, $30,000; Inventory, $10,000; Depreciation Building, $35,000; Depreciation Machinery, $25,000; Land $50,000. Total assets for this Corporation are what?A. $55,000B. $95,000C. $155,000D. $190,000E. $245,000

- Cash, $5,000 Machinery, $50,000 Building, $150,000 Savings, $10,000 Accounts receivable, $30,000 Inventory, $10,000 Land $50,000 - Depreciation Building, $35,000; - Depreciation Machinery, $25,000; = (E) $245,000

- Q: Holy Cow! What happens if the Holy Spirit comes over you while driving or operating heavy machinery?

- Hold on tight!!

- Q: in the indian mutiny what machinery was used in the war to fight?

- Canon, musket and the sabre..typical machinery for the 1850's.

- Q: What's the difference between a mechanical keyboard and a cherry axis?

- .Cherry MX mechanical axis is recognized as the most classic mechanical keyboard switch, the handle and gold contacts to the special quality of multiplication, and MX series of mechanical axis application on the keyboard mainly have 4 kinds, through the shaft cap color can identify, respectively, green tea, black, red and white (now discontinued) milk green grey nine common axis, feel is big, can satisfy the different needs of customers

- Q: I want to start export machinery spares parts from India. I don't know how to start? I did some research sent some email to foreign company but nobody replied..?? Please guide me step by step process. 1. How to approach foreign traders/foreign importers?2. How do I market my company?3. What are the legal procedure to export from India?4. What is market position for exporting machinery spare parts from India?

- Go to your board of trade in your community,importing Exporting the canadain goverment has booklets,when you dealing with another country you have to register your bussiness thats,insurance,bondable,frieght insurance,and the person that can help you is a custom broker there in the yellow pages,and you would have to look upindia custom,there tarrifs,its a lot but my suggestin is look for gov help,look on web site exporting products

- Q: Must be in machinery.

- Produces heat. Wears components out.

- Q: i want to find some suppliers who can provide corn germ oil machine and macaroni machine

- corn oil; do you mean bio diesel or other? macaroni machine?

Send your message to us

WCQ300G Stabilized Soil Mixing Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 2 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords