Lowest Price Clear Packaging Tape with Low Moisture Vapor Transmission Rate Aluminum Foil Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

Synthetic Rubber Based Aluminum Foil Tape is of aluminum foil as the carrier, coating with solvent based acrylic, synthetic rubber-resin, or water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Synthetic Rubber Based Aluminum Foil Tape: widely used for seaming and jointing bonding of various vapor barriers, fixing thermal fin in refrigerators. Provide fast and permanent bond performance for vapor barrier against the moisture.

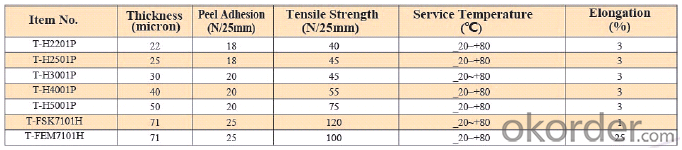

Typical Physical Reports of Synthetic Rubber Based Aluminum Foil Tape:

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Width1200mm; length according to customers’ requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Aluminum Foil Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Are there any regulations or standards for packaging tape?

- Yes, there are regulations and standards for packaging tape. These guidelines typically cover aspects such as strength, adhesion, durability, and safety. Organizations like ASTM International and the International Organization for Standardization (ISO) have developed standards to ensure that packaging tapes meet certain quality and performance requirements. Additionally, regulatory bodies in different countries may have specific regulations for packaging materials, including tapes, to ensure they are safe for use and compliant with applicable laws.

- Q: How do I prevent packaging tape from wrinkling?

- Here are some steps you can take to prevent packaging tape from wrinkling: 1. Utilize a tape dispenser: Using a tape dispenser aids in achieving a smooth application of the tape, reducing the likelihood of wrinkling. It also grants better control during taping, making it easier to keep the tape straight and taut. 2. Apply the tape tightly: When applying the tape, pull it firmly as you adhere it. This prevents any slack or loose areas that may cause wrinkling. Be cautious not to stretch the tape excessively, as this could diminish its adhesive properties. 3. Opt for the appropriate tape type: Different types of packaging tape possess varying adhesive properties and thicknesses. Selecting a high-quality tape specifically designed for packaging can minimize wrinkling. Additionally, consider using tape with reinforced fibers for added strength and resistance to wrinkling. 4. Ensure a clean surface: Before applying the tape, ensure that the surface is free from dust, dirt, or any other debris. These particles can cause the tape to wrinkle or adhere improperly. Thoroughly clean the surface and allow it to dry before taping. 5. Avoid extreme temperatures: Packaging tape can be sensitive to temperature changes, which may lead to wrinkling. Refrain from using the tape in extremely cold or hot environments. If possible, store the tape in an area with controlled temperature before usage. 6. Apply pressure: After applying the tape, use your hand or a roller to exert pressure on it, ensuring proper adhesion. This helps smooth out any potential wrinkles or bubbles and ensures a secure attachment of the tape. By following these suggestions, you can significantly diminish the likelihood of packaging tape wrinkling, resulting in a more orderly and secure package.

- Q: Can packaging tape be used for sealing packages with jewelry or valuables?

- Yes, packaging tape can be used for sealing packages containing jewelry or valuables. It provides a secure and reliable seal, ensuring that the contents of the package are protected during transit.

- Q: Does packaging tape come in different widths for different applications?

- Yes, packaging tape does come in different widths to cater to various applications.

- Q: Can packaging tape be used for sealing fabric?

- Packaging tape is not ideal for sealing fabric as it may not provide a secure and long-lasting bond. It is recommended to use fabric-specific adhesives or sewing techniques for sealing fabric.

- Q: Can packaging tape be used for sealing packages with fragile artwork or sculptures?

- Yes, packaging tape can be used for sealing packages with fragile artwork or sculptures. However, it is recommended to use additional protective materials such as bubble wrap or foam to provide cushioning and ensure the safe transportation of delicate items.

- Q: Can packaging tape be used for sealing plastic folders?

- Indeed, plastic folders can be sealed using packaging tape. Specifically designed to possess strength and adhesive properties, packaging tape proves apt for securing and sealing a range of materials, including plastic folders. By doing so, it aids in maintaining the security and protection of the folder's contents. Nevertheless, it is crucial to ensure the tape's proper and secure application in order to achieve a tight seal. Moreover, it is advisable to opt for a transparent packaging tape to avoid hindering the visibility of the folder's contents.

- Q: Is packaging tape easy to remove without damaging surfaces?

- Packaging tape is typically designed to be easily removed without causing any harm to surfaces. However, the ease of removal can vary depending on several factors, including the type and quality of the tape, the surface it is applied to, and how long it has been in place. Most packaging tapes are created to stick firmly to surfaces during transportation or storage, ensuring that the package remains sealed and secure. Nevertheless, they are also formulated to be peeled off easily when necessary, without leaving any residue or causing damage. In most situations, packaging tape can be removed by simply peeling it off slowly and evenly. The adhesive used in packaging tapes is generally developed to strike a good balance between sticking power and ease of removal. This allows for effortless removal without the need for excessive force or any sticky residue. However, there may be instances where the tape might be more challenging to remove, particularly if it has been in place for a long time or exposed to extreme temperatures. In such cases, using heat, such as a hairdryer, to soften the adhesive can be helpful, making it easier to peel off. It is important to note that the ease of tape removal can also be influenced by the surface it is applied to. Smooth and non-porous surfaces like glass or metal are generally easier to clean without causing any damage. On the other hand, porous or delicate surfaces like wood or painted walls may require more caution and care during removal to prevent any potential damage. In conclusion, while packaging tape is generally designed to be easily removed without causing damage, it is essential to consider factors such as tape quality, surface type, and removal technique to ensure a smooth and damage-free removal process.

- Q: How do I prevent packaging tape from becoming too loose?

- To prevent packaging tape from becoming too loose, it is important to ensure that the surface being taped is clean and free from any dirt or debris. Additionally, applying firm and consistent pressure while securing the tape can help create a stronger bond. If the tape still becomes loose, using a wider tape or applying multiple layers can provide better adhesion and prevent it from coming undone.

- Q: Does packaging tape have a specific shelf life?

- Indeed, there is a designated lifespan for packaging tape. The duration of this lifespan fluctuates depending on the type and caliber of the tape. In general, the majority of packaging tapes possess a shelf life spanning from one to two years. Nevertheless, this lifespan can be elongated or abbreviated due to certain factors such as storage circumstances and exposure to sunlight or extreme temperatures. It is crucial to consult the manufacturer's guidelines or packaging for any explicit instructions regarding the tape's shelf life. To guarantee optimal performance and adhesive potency, it is advisable to employ packaging tape within its designated shelf life.

Send your message to us

Lowest Price Clear Packaging Tape with Low Moisture Vapor Transmission Rate Aluminum Foil Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords