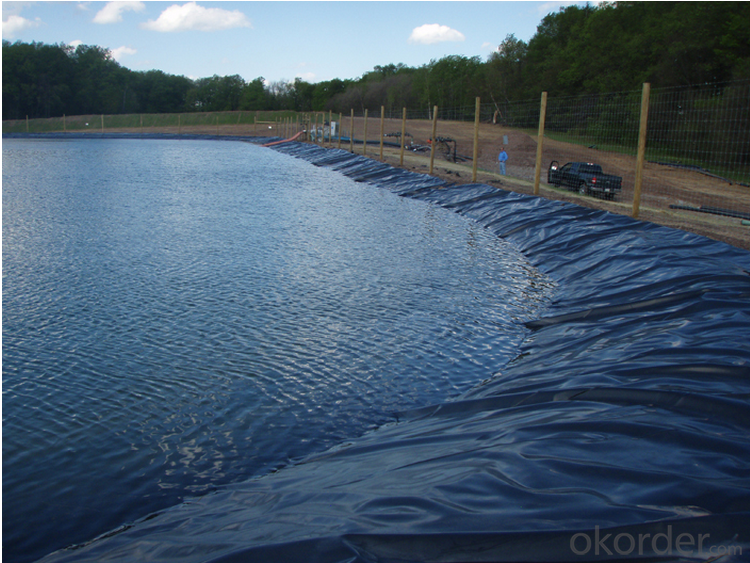

Waterproof HDPE liner/Geomembrane liner/fish pond liner roll

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

We can produce all models of high density polyethylene waterproof HDPE geomembrane liner for landfills, such as composite geomembrane, HDPE geomembrane, ECB geomembrane, EVA geomembrane, PVC geomembrane, smooth geomembrane, textured geomembrane, fish pond liner roll, geomembrane line, etc.

Characteristic

1.Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life.

2.Water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

Applicable scope

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti- dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

Project | Index | |||

GL | GH | |||

GL-1 | GL-2 | GH-1 | GH-2 | |

Tensile strength (MPa) | ≥14 | ≥17 | ≥14 | |

Break elongation (%) | ≥400 | ≥450 | ≥400 | |

Right angle tear strength (N/mm) | ≥50 | ≥80 | ≥50 | |

Carbon black content (%) | ≥2 | |||

Water vapor permeability coefficient (g.cm/(cm.s.Pa) | ≤1.0x10-12 | |||

-70 Low temperature brittleness properties | pass | |||

Dimensional stability (%) | ±3 | |||

FAQ

How about the delivery time?Lead time since receipt of 30% T/T deposit payment: 3 weeks.(Samples will be prepared within 3 days.)

2.What's are the MOQ?Generally speaking, the MOQ is one container, but we can provide you samples for quality inspection.

3. Do you charge for the samples?Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

4. Can you produce according to customers' design?Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: What is the difference between cement pond lotus and geomembrane harvest?

- Now with a good quality of the new material film, seepage is not good, the general use of geotechnical membrane to do high cost of impermeable cement

- Q: The pool with geomembrane but not long enough for what glue pool

- Should be used in geotechnical membrane professional welding, not long enough to play a role in the prevention of leakage,

- Q: Which one should be used for dam protection, geomembrane or wire box?

- Wire box, of course. It has good protection effect and can prevent the dam from landslide, water loss and soil erosion.

- Q: How to stick the film on the bathroom window?

- The first step: You should measure the size of the glass.The size of the film should match that of the window, in case of wasting the film. Next if you want the film to be perfectly stuck, then you must spray some water to reduce the dust befor sticking the film, creating a dustfree environment for the film. The second step: Before finhishing washing the glass, you should put a lint free towel under the window to be washed to prevent water from flowing to the outside, thus soaking walls. Cleaning the glass is a important step and it relates to the effect of the film. The third step: When sticking the film, you should spray some water on the both side of the film to remove attachments on the film attched by the static electricity. Then, you can tear off the plastci film on the glass film, spary water on it and stick it on the glass. After that, you can squeeze the the water out and cut needless edges. The fourth step: The final step is to check whether the film has been stuck well. You can check whether edges are firmly attached and whether there are bubbles and wrinkles. Only when it is certain that there is no problem with the film the process of sticking film has been complished.

- Q: What are the advantages of using geomembranes in chemical storage facilities?

- There are several advantages of using geomembranes in chemical storage facilities. Firstly, geomembranes provide a highly effective barrier against leakage, preventing any potentially hazardous chemicals from seeping into the soil or groundwater. This helps to protect the environment and prevent contamination. Secondly, geomembranes are durable and have a long lifespan, making them cost-effective in the long run. They are resistant to chemicals, UV radiation, and extreme weather conditions, ensuring the integrity of the storage facility. Additionally, geomembranes are flexible and can be customized to fit any shape or size of the storage area, allowing for efficient utilization of space. Overall, the use of geomembranes in chemical storage facilities contributes to enhanced safety, environmental protection, and cost efficiency.

- Q: How do geomembranes prevent water pollution in agricultural waste management?

- Geomembranes prevent water pollution in agricultural waste management by acting as a barrier between the waste and the surrounding environment, preventing the leaching of harmful substances into the water. They effectively contain and isolate the waste, preventing its direct contact with the soil and groundwater, thereby safeguarding water sources from contamination.

- Q: What are the limitations of geomembranes in high-chemical concentration environments?

- Geomembranes are typically used as barriers to prevent the migration of chemicals in various environments. However, in high-chemical concentration environments, there are several limitations to their effectiveness. Firstly, some chemicals may be highly reactive and can degrade the geomembrane material, leading to reduced performance and integrity over time. Additionally, certain chemicals may have a high diffusion rate, making it challenging for the geomembrane to effectively contain and resist their migration. Moreover, the presence of high chemical concentrations can increase the likelihood of punctures or tears in the geomembrane, compromising its ability to act as a barrier. Therefore, it is crucial to carefully consider the specific chemical properties and concentrations when selecting and designing geomembranes for high-chemical concentration environments.

- Q: What is the role of soot carbon particles in geomembranes?

- When carbon?blacks are evenly distributed, they can absorb ultraviolet light, protect products from aging too early and increase the life time of products.

- Q: Who exports geotechnical materials? I would like to ask how to calculate the loading quantity of geotextile, geomembrane and geogrid. For example, a 20 foot locker.

- It depends on the size of the material.

Send your message to us

Waterproof HDPE liner/Geomembrane liner/fish pond liner roll

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords