VIP Fireproof Calcium Silicate Micropore Insulation Boards

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fireproof Calcium Silicate Micropore Insulation Board:

Product Description:

Calcium silicate uses fireproof board, pipe and brick materials for aluminum, power, and cement, nonferrous and steel industries.

The main constituents of calcium silicate insulation boards and pipes are Xonotlite and reinforced glass fiber with no asbestos. Which is a high efficient energy-saving material with temperature limited 1050℃. Characterized by low bulk density, high specific strength, superior heat resistance, outstanding thermal insulation, excellent durability, chemical corrosion resistance, easy to be cut by saw and easy installation calcium silicate can be widely used for the insulation of industrial kilns.

With a density range of 800--1000kgs/m3,high density calcium silicate insulation boards are developed for the non-ferrous industry used for feeding, casting and molding of molten aluminum and used by other non-ferrous metals. They are also used for clamping fixture of glass properties. In addition to its insulation, its characteristic of non-stick aluminum exerts a large superior strength and with excellentprocess ability making it the preferred material for precision CNC machined parts and complex components.

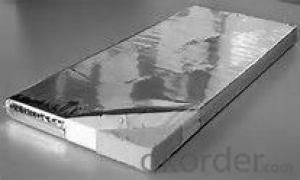

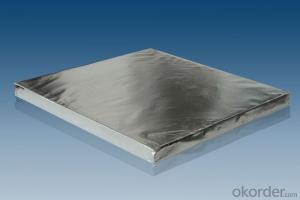

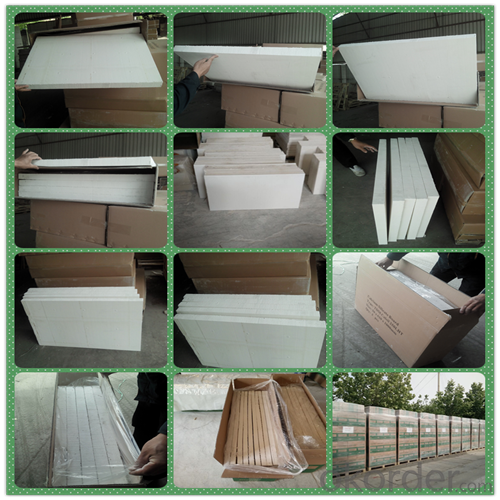

Products Images:

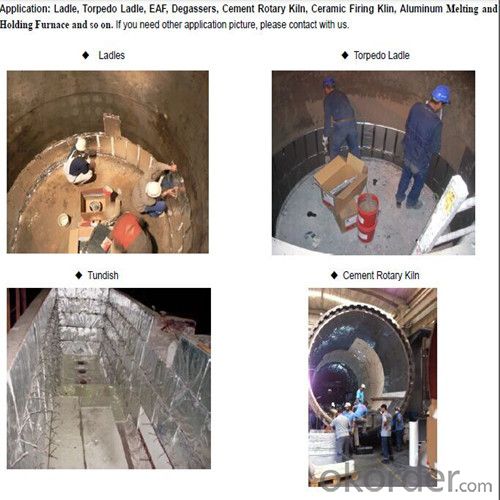

Product Applications:

· Cement industry: preheaters and cyclone separators, decomposition kiln, tertiary air duct and cooler.

· Nonferrous metallurgical properties: Electrolysis groove.

· Petrochemical properties: Splitting furnace, catalytic cracking furnace, petroleum pipeline, underground heat-flooding.

· Metallurgical industry(steel plant): hot-rolling heat furnace,cool-rolling mill set,RH vacuum degassing furnace , smelters,hot deformation and heat treatment plants.

· Power plant: preheat stove, pipe.

· Glass industry: melting furnace and recuperate, annealing furnaces and cooling channels.

Products Specifications:

Place of Origin: | China | Brand Name: | CMAX | Model Number: | Micropore Insulation Board | |

Material: | PTFE | Thickness: | 3mm-100mm, 3mm-100mm | Size: | Length & Width: 500mm*500mm, 600mm*600mm, 1000mm*1000mm 1200mm*1200mm | |

Certificate: | ISO9001:2000 ISO9001:2008 | Coating: | Alumina foil/ glass fiber cloth | Length & Width: | 500mm*500mm 600mm*600mm, 1000mm*1000mm, 1200mm*1200mm | |

Grade: | A grade (100% virgin) B grade (50% virgin) C grade ( 30% virgin) | Polytetrafluoroethylene: | PTFE, also named TEFLON. | Characteristics: | includes molded sheet and skived sheet | |

Applications: | used within -180℃~+260℃ | Delivery: | 7 days after the receipt of the deposit | Packaging | According to customer requirement.

| |

Packaging Details: | Paper-carton with polybag inside. Paper-carton with polybag inside and pallet. Paper-carton with polybag inside and shrinkable film and strapped. | |||||

Delivery Detail: | 25 Days | |||||

Minimum Order Quantity: | 100 kg | Unit: | kg | Loading Port: | Shanghai |

Supply Ability: | 10000 kg/month | Payment Terms: | TT or LC | Package: | carton box |

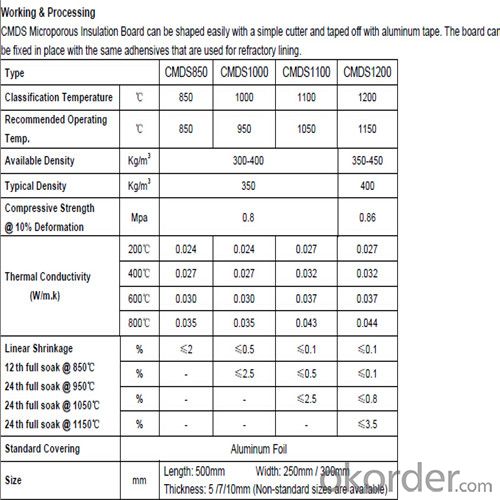

Technical of micropores insulation board

More Products To Choose

Our Services

1) High performance cost ratio with steady quality

2) OEM service and Prompt Delivery

3) The fast speed of reply your email and can make quotation sheet just for you.

4) Can provide free sample, only need you bear the sample fee.

5) Supply good after-sales service, we will follow-up the situation after using, if have problems,we will find out the

reason and deal with positively.

Other insulation products:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What about payment term?

A4: We accept 30%T/T in advance, with the balance before shipment. L/C at sight is also acceptable. Other payment term can be discussed with specific orders.

- Q: I ask, our home is the top floor, the summer is too hot, the walls and roof in addition to the use of insulation board, posted their own kind of tin foil, will not be useful?

- At present, the domestic brand is not clear who is using a good insulation board should be made of silica filler, because the BET for the nano-so the effect is better. Energy saving can reach more than 30 percent

- Q: Is the thermal conductivity of the vacuum insulated plate used to protect the hot plate method?

- Mainly in the 40 yuan / m or so, but the specific price depends on color steel sandwich panel core material and specifications to determine the model

- Q: What brand of refrigerator is using a vacuum insulation board? What kind of insulation board is better? More

- Aluminum generally refers to anodized aluminum, not magnesium alloy. Apple, Dell alien field arc spot some of the old roar M18x (note only M18x is, other models are not) XPS series, all the super class such as Acer hummingbird, Lenovo U300s

- Q: What is the best insulation material? To be waterproof.

- Specifications are generally diameter of 48mm wall thickness of 3.5mm; diameter of the bones of the fen fen shed leters light dog 51 degrees wall thickness of 3.0mm these two kinds of market is currently the country is almost 3900 yuan / ton buckle according to sets of about 5 yuan / set

- Q: External wall insulation material which is good, external wall insulation materials

- Indoor insulation material that the best, fire, environmental protection, good insulation effect? ??Glass fiber. Good insulation. Glass fiber cotton with numerous fine gas holes, fibers arranged irregularly arranged, heat conduction breakdown of 0.03w / cm.k, is an excellent insulation material; . with non-flammable. Glass fiber cotton will not burn, no deformation, no embrittlement, can withstand 700 degrees of high temperature, the combustion performance to A1; . environmental non-toxic. As the glass fiber cotton in the manufacturing process does not add any adhesive, so there is no smell, high temperature will not be distributed when the toxic, pungent smell, smell, etc .; . high insulation. As the glass fiber cotton used in the raw material is glass, non-conductive, so it has a very high insulation; . corrosion resistance. Glass fiber is not afraid of strong acid, with a strong corrosion resistance, even if the use of long time will not reduce its functional characteristics; . good recovery Glass fiber contains numerous fixed cavitation, with excellent recovery, not afraid of any shock, tensile strength are more than 1.0kg; . do not want to light field scrambled decanoate containing mutual water. The moisture absorption of glass fibers is usually close to zero, do not worry about there will be water swelling caused by wet cracking of the situation. I hope my answer can help you.

Send your message to us

VIP Fireproof Calcium Silicate Micropore Insulation Boards

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords