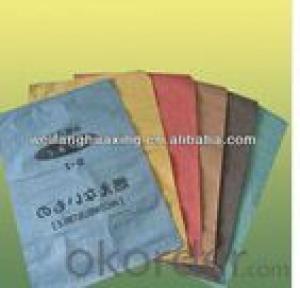

virgin material pp woven bags 50kg

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Material: | pp | Industrial Use: | feed grade | Feature: | Moisture Proof |

| Surface Handling: | Offset Printing | Sealing & Handle: | Top heat cut | Custom Order: | Accept |

| Place of Origin: | BEIJING China (Mainland) | Brand Name: | CMAX | Model Number: | CMAX |

| type: | pp bag | color: | white/red/yellow/pink/and other color | trade term: | FOB,CIF. |

| packing: | 1000pcs/bale | payment: | T/T | moq: | 11.5ton |

| delivery time: | 20-25days | Customer order: | Accept | Top: | Heat cut |

Packaging & Delivery

| Packaging Detail: | packing:1000pcs/bale |

| Delivery Detail: | 25-30days |

Specifications

manufacture for more than 15 years

two large factories in China and one large factory in Cambodia

60 tons daily capacity.

- Q: The package specifications are 9 multiplied by 14 plus 3. How big is it?

- The height of the bag is 14CM, the width is 9CM, and the width of the side is 3CM. The bag type belongs to the organ bag!

- Q: What are the bags and bags?

- According to functional categories: high Yin diaphragm bag, cooking film bag, anti-static film bag, antibacterial film bag, anti fog film bag, vacuum bag, anti chemical film bag, oxygen packing film bag, air conditioning packaging film bag, etc.

- Q: What kind of material is the express package on the market now? It's dark in the outer grey.

- The materials used for express bags are generally HD-PE, which can be recycled and can be re packed into bags

- Q: The shelf life of the package usually takes several forms

- Milk is extremely nutritious and therefore very perishable. In order to keep fresh and safe to consumers during circulation, the milk must be thoroughly sterilized and securely packaged. The sterilization method, compared with traditional pasteurization, the ultra high temperature sterilization (Ultra High, Temperature, UHT), can greatly reduce the milk color, flavor and nutritional value of the loss, and become the best and fastest way to the development of processing.

- Q: What material is the packing bag for pure milk, please?

- W1l203 (station contact TA) should be food grade polyethylene, safe, easy to tear learn1986 (station contact TA), aluminum foil and polyethylene plastic film and paper interaction combined into polyethylene aluminum plastic composite packaging materials.

- Q: What are the requirements of the gas in the package?

- The higher requirements are modified packaging: oxygen, nitrogen and carbon dioxide are used to fill the package in proportion to the product - respiration - use, to extend the shelf life of the product, and outside

- Q: What about the table of nutrition values on food packages?

- serving sizeThe nutrition information displayed in the nutrition information column is based on "every" or "every 100 grams". For foods such as bread, one may be one or two tablets, but for other foods, it may be a little more complicated. A portion that may be only part of the package, or may be part of the normal portion of the meal. Therefore, you need to multiply the actual amount of the food you eat by multiplying the values listed in the nutrition information. 100 grams or 100 milliliters each

- Q: What material should be used for transparent packing bags? How many cents do you want?

- PVC products for packaging containers, mainly for a variety of film and film. PVC containers mainly produce mineral water, drinks and cosmetics bottles, as well as packaging for refined oils. The PVC film can be used in CO extrusion with other polymers to produce low cost laminates and transparent articles with good barrier properties. PVC film can also be used for stretch or heat shrink packaging, used for packaging mattresses, cloth, toys and industrial goods.

- Q: What's the size of the 5 kg vacuum bag, please?

- Now the standard of living has improved, basically vacuum packed bags. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: What's bread packing? Polyethylene film, waterproof cellophane, etc.

- Currently, about 90% of the bags are packed in polythene plastic bags.

Send your message to us

virgin material pp woven bags 50kg

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords