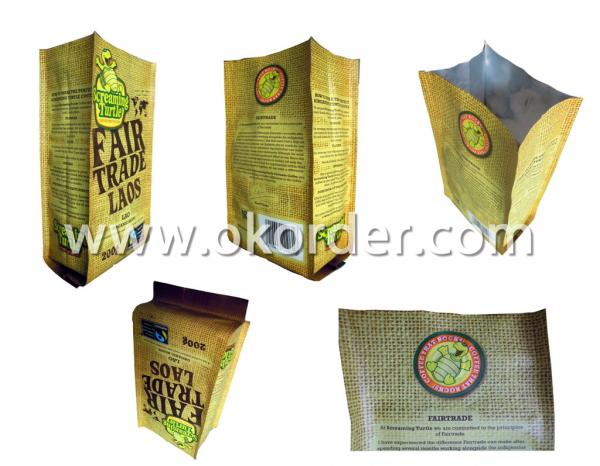

Side Gusset Bag With Quad Bottom

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000PCS pc

- Supply Capability:

- 500000PCS Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications Of Side Gusset Bag With Quad Bottom

1.Food grade material

2.Heat sealed

3.Durable plastic bag

2. Size and material: According to clients' request

3. Application: Beverage, fruit juice, jelly, cosmetic, food etc.

4. Printing: both are printed or non-printed

5. Style: stand up with spout, flat with spout, side gusset with spout, etc.

6. Food degade

7. Process: Heat sealed / High frequency welding / sewing.

8. Packing: individual poly bag or as per customer’s requirement

9. Suitable for showing the good on shelf easily.

10. Closed with spout, easy to take and use

11.These kinds of bags are in high quality with stable protection function

12.The bags can be made of different material to suit for package of different products.

More Information Of Side Gusset Bag With Quad Bottom

as following( Side gusset ziplock bag with quad bottom gusset ):

1): Safety material without any poisonous and passed all EU testing, SGS,

MSDS report both are available.

2): Excellent moisture barrier, low sealing temperature, and good low temperature resistance

3): High quality, Reasonable price

4): The bag style can be: Three sides sealing flat bag, zip lock bag,stand up bag with or without zip lock and so on.

5): We can also make the bag one side is clear, and the other side is foil,so you can show your inside products very well.

6): We print according to client's own design, we can print 12 colors in one time.All the machines are high speed computer controlled gravure printing machine,so can guarantee good printing quality.

7): Make the bag with tear notch and zip lock, and also with hang hole.

Tear notch: Easy to open the bag

Zip lock: Reuse anytime if you like, very convenient.

Hang hole: Hang the bag on a hanger to save space.

Notes Of Side Gusset Bag With Quad Bottom

1) Please kindly inform us of the material, thickness, size, printing color and other requirements you prefer,2) We can produce various packaging bags& packaging film rolls as per customer's requirements, if necessary, we can also give some advice for your reference.

The Pictures Of Side Gusset Bag With Quad Bottom

- Q: What kind of material is the packing bag of ceramic tile?

- There are three paper kraft paper composite film, color film, color film lamination, lamination, lamination and color printing paper, woven bags and other materials, can do

- Q: What does "TM" mean in a food package?

- Its role is to tell people that it is marked by the graphics or text of the goods or services of trademark, not the name is not advertising. English and "R" is the abbreviation of "register", "register" Chinese means "registered", goods or services on the mark that is told people, it marked the graphics or text but not trademarks, and registered trademarks, protected by law, unauthorized, unauthorized use can not be any other individuals and organizations.

- Q: How to evaluate the quality of a food packaging bag design? From what angle?

- Successful packaging must be eye-catching. This can only be used as a horizontal contrast. In the same environment, the most striking one is the one that can be distinguished from other products at one glance. Also take the moon cake as an example, the Mid Autumn Festival, the general moon cake gift box is red, golden yellow based, above is not the moon, is the flower, most of them are like this. If the design is blue, the package is also shown in the same area. Must be the most striking.

- Q: Is the packet in the food package a reducing agent or an oxidizing agent?

- The ingredients of food reducing agents are some vitamins, phenols, iron powder and so on. Because these substances react readily with oxygen, they protect the food from being oxidized,

- Q: What are the requirements of the mark on the cement packing bag?

- Cement gradeCement is divided into strength grade: 1, Portland cement strength grade is divided into 42.5, 42.5R, 52.5, 52.5R, 62.5, 62.5R six levels. 2, ordinary portland cement strength grade is divided into 42.5, 42.5R, 52.5, 52.5R four grades.3. The strength grades of slag Portland cement, volcanic ash Portland cement, fly ash Portland cement and composite Portland cement are divided into 32.5 grades: six, 32.5R, 42.5, 42.5R, 52.5 and 52.5R.

- Q: What are the characteristics of a good package?

- This mainly refers to the packaging can perfectly protect and preserve the goods in the design of material selection, structure, can effectively cooperate with transportation storage loading and unloading circulation operation; enable consumers to use the goods, carrying and preservation is more convenient. In addition, whether the packaging material will cause pollution to the environment, and whether recycling is also very important. Packaging industry is a scientific and systematic project, and the packaging design must take into account the scientific aspects of each link, which also reflects the combination of art and science characteristics.

- Q: Is there any identification on the vacuum package?

- DOD on demand machine (drop) for short, called ink jet printer. The working principle: the nozzle is made up of several high precision valves. When the word is sprayed, the corresponding valve is opened and closed quickly. The ink is ejected by the constant internal pressure, forming characters or graphics on the surface of the movement.

- Q: What are the requirements of the gas in the package?

- Some of the most common baked foods, moon cakes, fried foods, potato chips, which are filled with nitrogen, are required to be food grade, high purity, minimum requirement is no harmful gas impurities!

- Q: What are the common materials of tea packing bags?

- PE bag (plastic bag)Polyethylene bags, or PE bags, are widely used packaging materials at present. There are two kinds of low density PE bags and high-density PE bags. The low density PE bags are breathable and breathable, while the high-density PE bags are smaller.The advantages of PE bag are economical, cheap and damp proof. Its disadvantages are light transmission and poor air resistance. It can not be used in tea packaging individually. The best can add a layer of light resistance and low permeability of the outside packaging using polyethylene bags, such as synthetic paper cans, cans and other PE bag permeability is bigger, also difficult to solve the problem of oxygen in the packaging bag, and is not the ideal packaging material.

- Q: What are the types of composite packaging bags?

- Folding containerA large volume of transport package, the weight of more than 1 tons. The top of the container is usually equipped with metal hangers or rings, which is convenient for lifting and transporting of forklifts or cranes. When discharging, it is possible to open the discharge port at the bottom of the bag and unload the cargo conveniently. Suitable for shipment of granular or powdery articles.Container bags are usually made of polyester fibers such as polypropylene and polyethylene. Because the container loading and unloading of goods, transportation is very convenient, improve handling efficiency, in recent years made shoes soon.

1. Manufacturer Overview

| Location | Foshan, China |

| Year Established | 2005 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | Mid East, Northern Europe, Eastern Asia, Eastern Europe, Southeast Asia, Western Europe, Southern Europe |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen; |

| Export Percentage | 5% - 10% |

| No.of Employees in Trade Department | 50-100 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 9 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Side Gusset Bag With Quad Bottom

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000PCS pc

- Supply Capability:

- 500000PCS Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords