Vial Tubing Plane Shoulder Vial, Slanted Should Vial

- Supplier:

Triumph Junheng Co.,Ltd

Triumph Junheng Co.,Ltd

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 pc

- Supply Capability:

- 1000000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vial Tubing Plane Shoulder Vial, Slanted Should Vial

The converting products workshop of the plant has a 100000-level clean room that meets GMP standards, which provides superior production conditions for the production of glass containers and effectively avoids the impact of dust and bacteria on product cleanliness. The inspection system with 7 cameras and 360 continuously rotating and shooting, to detect the glass container body,mouth, shoulder, bottom,inner diameter,edge blind area and mouth bottom edge, as well the dimension, objects inside the container, cosmetic defects (bubbles, impurities and stones).The unqualified products such as crooked container are automatically eliminated, with a detection accuracy of 0.02mm, which ensures that the quality of the glass containers can reach the domestic YBB standard and the international ISO standard. "Excellence Centre"is a project established by Triumph Group and the world leading pharmaceutical packaging material manufacturer-Stevanato Group(Italy). The goal is to introduce world standard tubular glass containers production technology, technical process and quality standards to the Chinese market and make our company's products to keep up with international top standard.

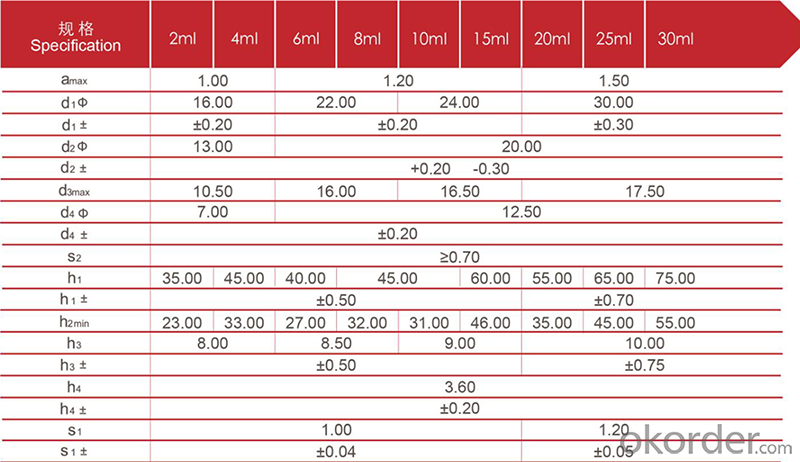

Vial Tubing Plane Shoulder Vial

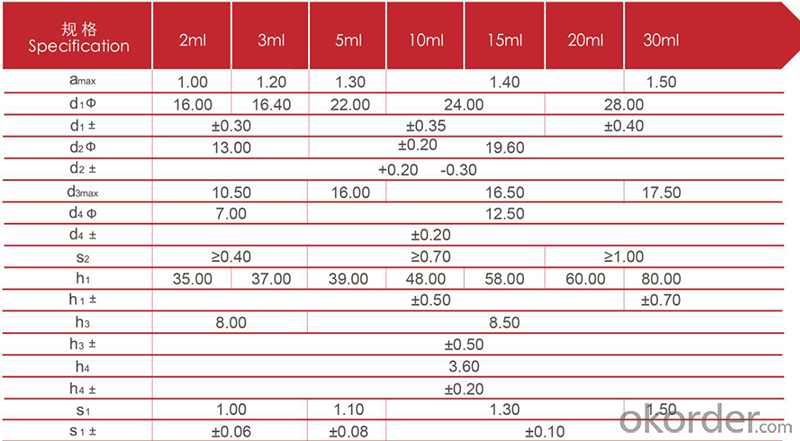

Vial Tubing Slanted Should Vial

Nationwide Seven Production Bases to Meet the Customers' needTriumph Junheng Co.,(hereinafter referred to as "Triumph Junheng") is a state-owned andprivate mixed ownership enterprise, Triumph Group of CNBM is the controlling shareholder.It ismainly engaged in the research and development, producing and sales of neutral Borosilicateglass tubing(hereinafter referred to as "Neutral Borosilicate glass tubing") and convertingtubular glass products. It has seven production bases located in Handan, Qingdao, Chongqing,Puyang, Anyang, Nanchang and Zhenjiang, which are expected to produce totally 170,000 tons of glass tubing and 136,000 tons of tubular glass container when they are reach full capacity. It is the first high-tech company which realizes stable mass production of high-quality Neutral borosilicate glass tubing with its "oxygen combustion + electric boosting"melting and Danner Tubing drawing technical process in China. It has leading R&D capabilities in the domestic pharmaceutical glass packaging industry, and can provide professional and personalized solutions of pharmaceutical glass packaging materials for materials for tubular glass converting and pharmaceutical companies.

Triumph Junheng builds a comprehensive research and development center for pharmaceutical neutral borosilicate glass in accordance with CNAS certification specifications. Continuously improve the level of laboratory quality management, minimize product quality risks, and meet the requirements of customers and regulations for the authenticity and reliability of testing/calibration to the greatest extent. The R&D center has a team with 30 people, covering various key technical fields such as raw materials analyzing, batching, melting, forming,and post-processing. The center has a building area of 800 square meters and consists of a precision instrument room, a physics laboratory, a chemical laboratory, a balance room, and a high temperature laboratory., Reagent room, equipped with 30 sets(sets)of R&D equipment such as atomic absorption spectrometer, expansion coefficient meter, and electron microscope. The R&D

center focuses on new technologies, intelligence, low energy consumption, localization and standardization, and actively undertakes national and local R&D projects to continuously achieve new technological breakthroughs.

Companys proucts have passed the Qulity inspection and Testing conducted by the national authoritative inspection agencies: Beijing Pharmaceutical Packaging Materials Inspection Institute and International Third Party Testing Agency-SGS. The product quality is fully in line with EP (European Pharmacopoeia), USP United States Pharmacopoeia),JP (Japanese Pharmacopoeia),According to the standard requirements of ISO12775 and the standard of "Neutral Borosilicate Glass Tubing" with Code YBB0012005-2-2015 approved by The National Food and Drug Administration. The expansion coefficient, boron content and hydrolitic resistance of products all have reached the international advanced level.

Quality Inspection

The international advanced automatic online inspection system has been adopted in the production line, which can automatically eliminate unqualified products with defects of dimension and cosmetic and unaligned ends treatment.

Automatic Packaging System

The automatic packaging system can complete the work of heat-shrinking into bundles and stacking into trays, effectively avoiding cosmetic defects such as scratches and impacting caused

by manual operation, ensuring the fastening of each bundle of products and the neatness of each tray.

- Q: Ceramic pots are sprayed glaze, or the whole porcelain crystallization good?

- Ceramic crystallization: glass ceramic composite board is the product of "three in one" of glass, ceramic and stone craft. It combines the glass melting process, ceramic brick molding and crystallization sintering process, stone polishing, cutting process as a whole. In short, microcrystalline glass frit is special stalls shop in the special ceramic tile on the roller kiln sintering crystallization, after polishing and cutting timber.

- Q: Twilight wall hollow glass with glass Zha glue with what is best?

- The raw materials of the latter two kinds of insulating glass are glass, aluminium strip, insert angle, butyl glue, double component polysulfide glue or silicone rubber, drying agent and compound sealant.

- Q: Do solar panels use toughened glass, or are some high light transmitting materials good?

- Ultra white glass raw materials imported or made of iron high transmittance (transmission rate of up to 92%), through tempering (heating quenching), so that the strength of the glass increased 3--5 times, broken glass debris particle degree of safety, no harm to human body. The thickness of 2MM, 3MM, 3.2MM 4MM, etc..

- Q: List and characteristics of chimney glass flake cement

- Coatings containing glass flakes are much harder than epoxy or polyester resin without glass flakes, and therefore have higher surface abrasion resistance.

- Q: How can the vacuum tubes of solar water heaters be chromatic aberration? Is purple good or sky blue good?

- Features: three, the absorption ratio of executives increased by 12%, the emission ratio decreased by 30% - 40%, super absorption, less heat loss, warming faster. Efficient tube, super absorption, high thermal efficiency, fast heating, in the same light condition, tube can be more than ordinary high temperature hot water; cold tube, due to launch Bibi aluminum ion copper ion is 0.2 lower, so the heat loss is small, can still work normally in the alpine environment, 30 degrees as often out of hot water; high temperature tubes, stainless steel for ion film high temperature resistant, anti air drying coating under the condition of 400 DEG C, aging, decay and discoloration.

- Q: How to seal the glass fiber reinforced plastic mould?

- Rubber pad seals are thickness, will be relatively increased parting surface gap, for complex, not good concave convex surface, uneven surface, you can use ordinary fastening before playing glass glue or fastening hot melt gun hit again. It can be divided into surface on floor wax coat material brush, then fastening glass steel mold.

- Q: Consult the experts on injection molding. Injection of raw materials Riga glass material, OK?

- There are many kinds of glass fiber material, such as PP, PA, ABS, PC and so on, which can be used according to needAdd different amounts of glass fiber

- Q: Aluminum alloy window material is good, how to assemble?

- Glass block: chloroprene rubber, polyethylene and nylon lead block. It is two kinds: the first is to glass and Aluminum Alloy slot and slot bottom metal parts separated by a gap, to ensure control of glass and metal frame relative size effect; second is to prevent the glass due to stretching and metal parts of the collision.

- Q: How is glass made? What material is it made of?.

- Bulletproof glass is the most important indicator of bullet proof ability. The target of bullet proof ability is measured from two aspects. On the one hand, it is the ability of security protection; on the other hand, it is the kill ability of the protective guns.

- Q: FRP process piping manufacturing process?

- A, lined with resin preparation. According to the quality control department according to the work environment, temperature conditions made resin formula system for lining resin matching, batching quantity according to the manufacturing schedule reasonable grasp. When the situation changes, the quality inspection department and the manufacturing department shall adjust the formulation in time, and prepare the resin according to the new formula;B, material preparation. According to the design requirements, the material needed for making the lining is transported to the designated position, and some wide width reinforcement materials are firstly cut and processed to the design width;C, lining production. According to the design requirements of the paving layer step liners, each layer in the process of laying under reasonable tension between the amount of overlap, and combined pressure roller rolling repeatedly from bubble to ensure fiber soaked completely. And requests each enhancement material layer to achieve the design resin content request;D, preliminary self check. According to the design requirements of overlay end of each layer, the operation requirements for quality testing of workers: whether the design meets the lining thickness, whether there is a local poor glue, hanging glue phenomenon, whether there is a white spot, whether there is a bubble, etc., if the occurrence of the above situation timely report and take measures;

Send your message to us

Vial Tubing Plane Shoulder Vial, Slanted Should Vial

- Supplier:

Triumph Junheng Co.,Ltd

Triumph Junheng Co.,Ltd

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 pc

- Supply Capability:

- 1000000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords