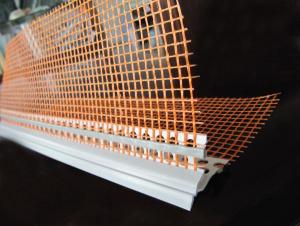

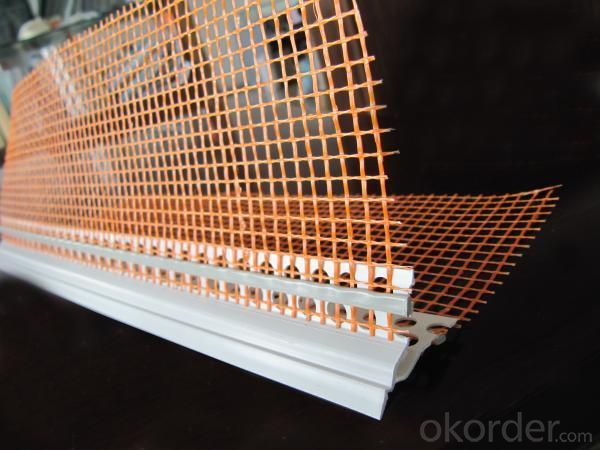

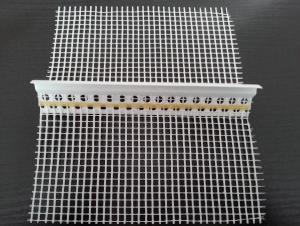

PVC Corner Bead With Fiberglass Screen Wire Mesh

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M m

- Supply Capability:

- 200000M/MONTH m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

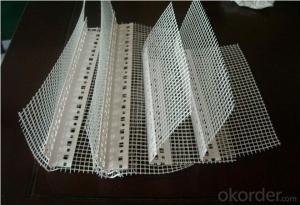

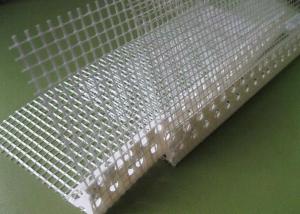

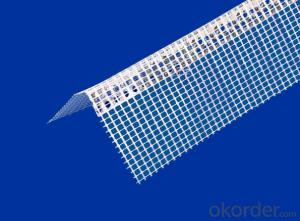

Specifications of PVC Corner Bead With Fiberglass Screen wire Mesh:

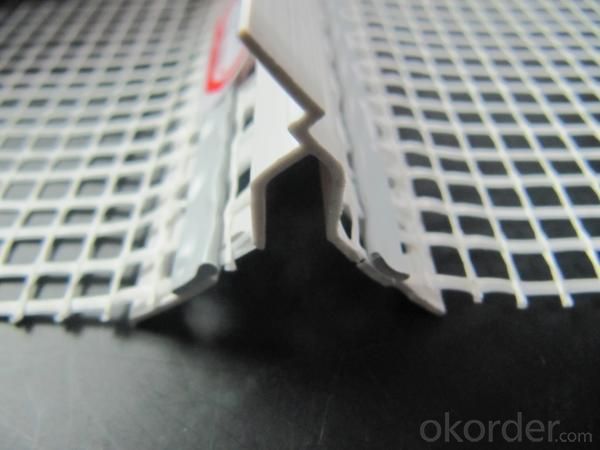

PVC corner bead with FIberglass screen wire mesh cloth is corrosion resistant, flexible and make the installation of the edge quicker,it can reinforces exterior stucco corners,make the corner hard-to-damage, rustproof,straight,and easily curved for smooth arches.

Length: 2.50m - 3.0m

Mesh Cloth Width: 8+ 12cm or 10+ 15cm

Mesh Weight: 145 g/m2

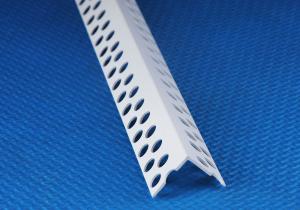

Width of Bead: 20mm

Thickness of Bead: 1mm

Weight of Bead: 70g

Usage/Applications of PVC Corner Bead With Fiberglass Screen wire Mesh:

PVC Corner Bead With Fiberglass Screen Wire Mesh has been widely used in all kinds of outdoor and indoor of building to protect the wall corner.

PVC corner is molded and extruded with rigid PVC compounds. It can be used for exterior and interior wall corner. Various sizes are available with high quality standard.

PVC corner has been widely used in all kinds of outdoor and indoor of building,major function is to protect the wall corner and anti-bumping, meanwhile save the cost of construction, speed up the construction process.

Packaging & Delivery PVC Corner Bead With Fiberglass Screen wire Mesh:

Pieces are put into carton.

- Q: How should the TV wall be installed on the corner?

- European style TV wallIf your favorite European country style, then the iron carving, beautiful color painting, created by the wall of the TV cabinet, plus dotted with porcelain, antiques, this is a typical European country style. Such a TV wall can feel as if it were in a picturesque nature.

- Q: How to solve the corner problem in the kitchen basket?

- The utility model can not only maximize the use of the built-in space, but also make full use of the waste space at the corner so as to maximize the use value.

- Q: What do you mean by corner steering of Bao Chun 730ABS steering wheel?

- The steering wheel sensor usually uses three mechanical structures to measure the angle and the number of turns. The large gear rotates along with the steering tube column, and the teeth of the two pinions differ by 1, and are fixed in the body with the sensor casing, and do not rotate with the steering wheel. The two small gears are respectively collected with the rotation angle of the steering wheel, and because of the difference of one tooth, the number of different turns will be different from the specific angle, and the absolute rotation angle of the steering wheel can be obtained by calculation.

- Q: Automatic CNC band saw machine, product use and advantages?

- Trolley type CNC feeding band sawing machine with rotary angle of 0 degrees to 45 degrees: real and the workpiece rotation, can be completed from 0 degrees to 45 degrees between the bevel of arbitrary angle.

- Q: Large angle hinge is used at the corner of the cabinet

- If it's on the corner counter, there's no problem with the 270 degree hinge!

- Q: Shops corner how to decorate?

- Just make a publicity campaign based on your product

- Q: CAD see others tagging is the corner mark, how to mark it out?

- The corner mark in AutoCAD, this name is a bit special. In fact, when a horizontal or vertical distance is marked in linear form, the completed annotation is the corner mark.

- Q: What's the corner line?

- Artificial stone corner line, including angle line and pressing strip (1), including the outer corner angle line line (2) and the inner corner line (3), which is characterized in that the pressing strip (1) and body is fixedly connected with the corner line;

- Q: What is called "Liu Cha"? Waterproofing materials to leave masonry angle will have Cha, cha.

- The products are mainly asphalt waterproof roll and macromolecule waterproof roll.

- Q: Pcliao injection of smooth surface not light is going on

- This defect is commonly believed to occur frequently during die filling and pressure holding. In fact, dark spots appear near the gate and usually occur at the beginning of the injection cycle. Tests show that the occurrence of surface slip is actually due to the injection speed, or rather the flow velocity at the tip of the melt flow.

1. Manufacturer Overview

| Location | Zhejiang,China |

| Year Established | 2007 |

| Annual Output Value | |

| Main Markets | North America, South America, Western Europe, eastern Europe, southeast Asia, the Middle East |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Corner Bead With Fiberglass Screen Wire Mesh

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M m

- Supply Capability:

- 200000M/MONTH m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords