Peel Ply-vacuum infusion process fiberglass

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Peel Ply

Product Description

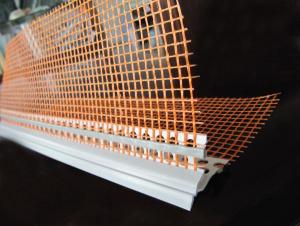

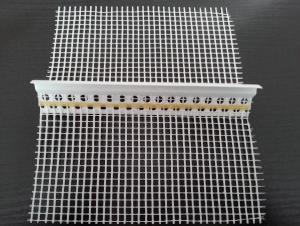

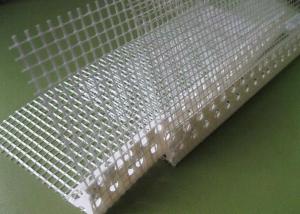

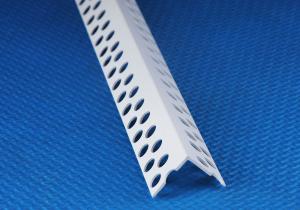

Peel Ply is a plain weave nylon fabric with red or blue stripe. Under scoured and heat set process, the surface is very clean and the fabric is very strong which gives perfect release property, widely used in vacuum infusion process, Aerospace, Wind power, Marine, fiberglass or carbon fiber vacuum infusion etc.

Technique Data

Material: | PA66 nylon fiber |

Area Weight: | 85 g/m2 can be customized to 105g |

Width: | 2500px (max 4500px) |

Temperature resistant | 230℃ |

Pattern: | plain weave |

Thickness: | 0.16 mm |

Color: | white+red stripe line |

Density: | 17 X 17 counts/cm |

- Q: How can the aluminum alloy window be fixed with the corner and the whole frame?

- Foshan windows and doors mature products manufacturers have matching doors and windows products dedicated corner, because the corner and the doors and windows connected to the width of the frame to coordinate. Generally used corner has 90 degrees, 135 degrees, and universal corner. Albert doors and windows have a complete solution.

- Q: How to solve the corner problem in the kitchen basket?

- The design of the basket at the corner solves the awkward position problem of the cupboard, and the reasonable partition is suitable for placing small objects of various sizes, and the extraction design is also convenient. If your home is not a font cabinet, it will certainly change direction in the cabinet when there is a corner space. Various corner pull baskets are the best solution for cabinet corner cabinets. When the cabinet of these two doors open, people do not sigh the way to accept the ultimate. Although the contents of the collection of many and miscellaneous, but each layer of a layer to show in front of, at a glance.

- Q: Large angle hinge is used at the corner of the cabinet

- They are high-end products, the general accessories are pure imports, new technologies and technologies are also used more. So I should know, I hope I can help you!

- Q: Steering wheel angle sensor operating principle

- In addition, through the photoelectric encoder to collect corners, but in automotive applications, due to the reliability of photoelectric sensors and other issues, the use of less products, not much described here.

- Q: What are the applicable industries of corner labeling machines?

- You can see the XYJ-T-PZ10A0R automatic corner sealing fast Yijie labeling machine, dedicated to the box corner labeling, in the box on the plane and the plane angle of side labeling, to prevent open function.

- Q: CAD see others tagging is the corner mark, how to mark it out?

- 1. enter the linear callout command DLI, select the object to be marked.2. enter R, carriage return.3., enter the mark to rotate angle, note: enter the positive angle mark, according to counterclockwise rotation, input negative angle mark, clockwise rotation.

- Q: What's the corner line?

- The composition and content of the corner line body are as follows: (weight percentage): unsaturated polyester resin 22 to 70%; filler 28 to 74%; curing agent 0.1.5%; promoter 0.1.5%; pigment 0.2%.

- Q: What is called "Liu Cha"? Waterproofing materials to leave masonry angle will have Cha, cha.

- Waterproof material is mainly used for building wall, roof and tunnel, highway, landfill, etc., to resist the external rain, groundwater seepage can be a flexible coiled coiled material products, as no leakage between the foundation and building connection, the whole project is the first barrier of waterproof, plays a vital role the effect of the whole project.

- Q: Pcliao injection of smooth surface not light is going on

- This defect is commonly believed to occur frequently during die filling and pressure holding. In fact, dark spots appear near the gate and usually occur at the beginning of the injection cycle. Tests show that the occurrence of surface slip is actually due to the injection speed, or rather the flow velocity at the tip of the melt flow.

- Q: Does the slot plate have a routing board with a 90 degree angle when it is wiring?

- The line groove board is also called "rubber line trough board" and "cable trough plate", providing temporary line and pipeline security products, belonging to rubber products.

Send your message to us

Peel Ply-vacuum infusion process fiberglass

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches