Ceramic Fiber Bulk Ultra Pure Heat Insulation Ceramic Fiber Bulk Std

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

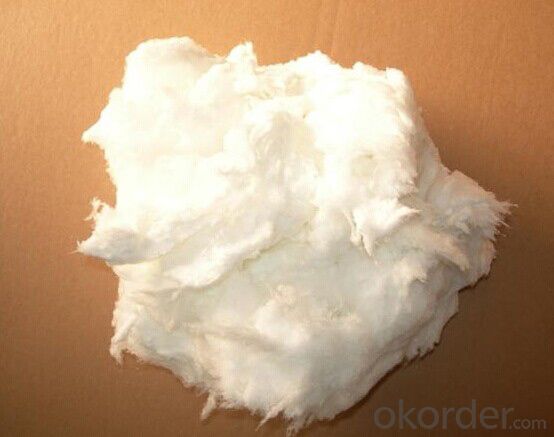

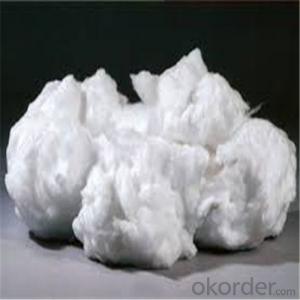

General Information of Ceramic Fiber Bulk

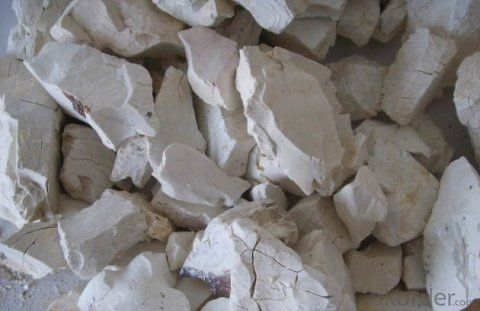

CMAX ceramic fiber Bulk is made from high quality Gao-Ling clay, high purity alumina and silica oxides by spun or blown process. It is asbestos free. Double-side needling provides Bulk with great tensile or handing strength for easy installation.

The products are classified as STD, HP, HA, and HZ respectively corresponding to different maximum service temperature 1000℃,1100℃,1200℃ and 1350℃

Feature of Ceramic Fiber Bulk

Heat resistance

Light weight

Low thermal conductivity

Low heat storage

Resilient to thermal shock

High tensile strength

Application of Ceramic Fiber Bulk

Petrochemical process heater refractory fiber lining

Heat treating furnace or Intermittent(shuttle) kiln hot face lining

General furnace backup insulation

Heat seals for kiln car or furnace door

Electrical insulator

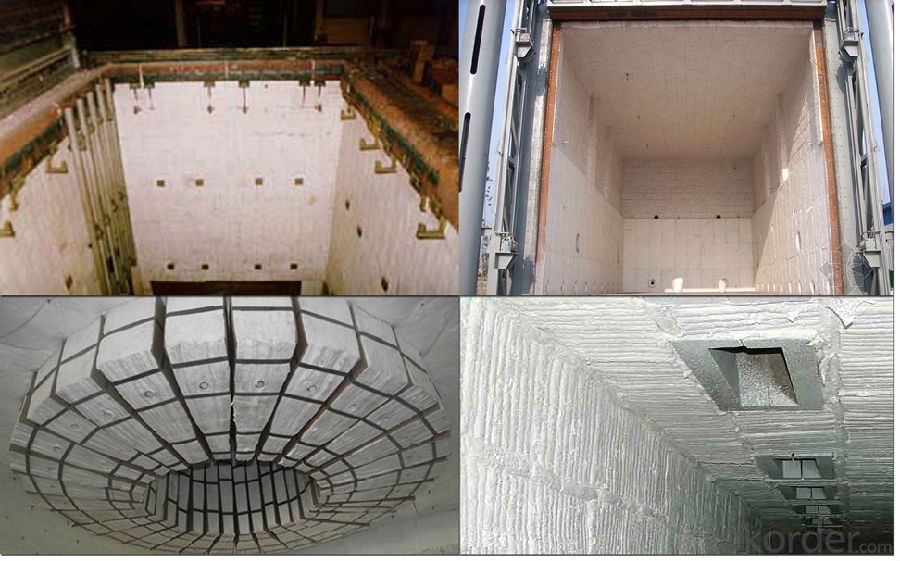

Picture of Ceramic Fiber Bulk

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. How do you control the products quality?

With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervise.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density is only a standard in the world, is 220Kg/m fand, but in the actual application, according to the heat treatment furnace, furnace temperature, combustion medium, temperature rise requirement of ceramic fiber module density in 200-240Kg/m fand, ceramic fiber blanket, because the processing of ceramic fiber module uses double roller today advanced technology and technology of silk, fiber length of the ceramic fiber blanket which produced in 80-130 mm, so the maximum density of the ceramic fiber module is more than the density, 240Kg/m fand, a large amount of fiber fracture, the fracture rate is as high as 48%. So after the actual verification at home and abroad of tens of thousands of industrial furnaces, the best density of ceramic fiber module is fand 220Kg/m.

- Q: Should the ceramic fiber furnace be compacted?

- In view of the large industrial furnace, the ceramic fiber module can be chosen to be refractory, heat insulated and insulated, and the ceramic fiber module is firmly fixed on the furnace wall by the parallel mounting method, which is more reliable

- Q: What is the difference between the ceramic fiber cloth and the high silicon oxygen cloth?

- 1. Ceramic fibers are short fibers that need to be strengthened and toughened by other objects. They are generally toughened by glass fiber and stainless steel wire.2 and high silicon oxygen is long fiber, no need to toughen by other objects.3 short, high silicon oxygen resistance to high temperature, Suzhou Dexin ceramic high silica cloth of silica content is greater than or equal to 96% temperature up to 1700 DEG C.

- Q: Glass fiber cotton, aluminum silicate cotton, rock wool, what's the difference between these three?

- Rock wool: is a kind of insulation materials, widely used in exterior wall insulation, because rock wool dust carcinogenicity, the state has banned the use of industry.

- Q: Aluminum silicate ceramic fiber cotton smoke will cause pneumoconiosis?

- Most of the aluminosilicate ceramic fiber cotton with high quality bauxite, high purity alumina, silica, zircon sand as raw materials, by blowing or swinging method generated by fiber, cotton collector or settlement device assembled into bulk fiber, also known as cotton fiber. Therefore, according to its composition, after inhalation, will lead to pneumoconiosis.

- Q: What is the diameter of the ceramic fiber? How to mix?

- Fiber diameter: rejection fiber more coarse, rejection fiber generally 3.0-5.0 - m, spinneret fiber is generally 2.0-3.0 - m;

- Q: What is the good heat insulation effect of glass fiber and aluminum silicate fiber, what are their respective advantages and disadvantages?

- Adiabatic effect: glass fiber thermal conductivity at room temperature was about 0.056, the thermal conductivity at room temperature is about 0.035, due to the lower thermal conductivity, moisturizing effect is better, so the material characteristics of aluminum silicate fiber insulation effect is good, but also with the insulation effect of fiber compression density, can not be generalized.

- Q: The difference between the ceramic fiber blanket and rock cotton blanket

- Ceramic fiber lining: low thermal conductivity of ceramic fiber lining in the average temperature of 400 degrees, the thermal conductivity is less than 0.1w/mk, the average 600 degrees less than 0.l5 w/mk, average 1000 degrees less than 0.25w/mk, about l/8 as a lightweight clay brick, lightweight refractory lining l/10, adiabatic effect.The construction of ceramic fiber lining is simple: no expansion joints are needed during construction, and the construction personnel can be started after the basic training. The technical factors of construction have little influence on the insulation effect of the lining.

- Q: Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminum silicate needle carpet should be aluminum silicate needled blanket, with the continuous production, by acupuncture fiber uniformity, high tensile strength, does not contain any additives. Ceramic fiber, also known as aluminum silicate fiber, is only a different name.

- Q: Ceramic fiber material fire shutter door how many square?

- There is no full ceramic fiber material fire shutter;

Send your message to us

Ceramic Fiber Bulk Ultra Pure Heat Insulation Ceramic Fiber Bulk Std

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches