Ceramic Fiber Bulk 1260 HP - High Performance Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 KG kg

- Supply Capability:

- 1000 Tons Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

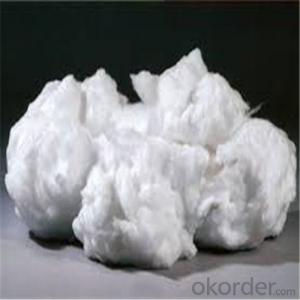

Ceramic fiber bulk 1260℃ HP

CMAX ceramic fiber bulk is made from high quality Gao-Ling clay, high purity alumina and silica oxides by spun or blown process. It is the optimum material for the production of fiber textile and also the perfect material for sealing, filling and insulating in high-temperature environment.

The HP Ceramic fiber bulk have temperature classification 1260℃(2300℉) and the recommended service temperature up to 1050℃(1922℉).

Feature of Ceramic fiber bulk 1260℃ HP

Heat resistance

Light weight

Low thermal conductivity

Low heat storage

Resilient to thermal shock

Application of Ceramic fiber bulk 1260℃ HP

Textile manufacture

Chimney fill

Expansion joint packing

Wet process feedstock

Filtration media

Kiln car infill

Technical Data

Package of Ceramic fiber bulk

- Q: What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density is only a standard in the world, is 220Kg/m fand, but in the actual application, according to the heat treatment furnace, furnace temperature, combustion medium, temperature rise requirement of ceramic fiber module density in 200-240Kg/m fand, ceramic fiber blanket, because the processing of ceramic fiber module uses double roller today advanced technology and technology of silk, fiber length of the ceramic fiber blanket which produced in 80-130 mm, so the maximum density of the ceramic fiber module is more than the density, 240Kg/m fand, a large amount of fiber fracture, the fracture rate is as high as 48%. So after the actual verification at home and abroad of tens of thousands of industrial furnaces, the best density of ceramic fiber module is fand 220Kg/m.

- Q: What is the difference between the ceramic fiber cloth and the high silicon oxygen cloth?

- High temperature is similar to that of strength, service life, the price is high silica cloth. High silica fabric belongs to glass fiber.

- Q: Glass fiber cotton, aluminum silicate cotton, rock wool, what's the difference between these three?

- Rock wool: is a kind of insulation materials, widely used in exterior wall insulation, because rock wool dust carcinogenicity, the state has banned the use of industry.

- Q: Aluminum silicate ceramic fiber cotton smoke will cause pneumoconiosis?

- Because pneumoconiosis can not be cured by medical treatment, it brings great pains to the patients and the families. It is suggested that respiratory protection work be carried out.

- Q: Is the ceramic fiber cloth poisonous?

- With aluminum, zinc and other non-ferrous molten metal erosion capacity. Excellent high temperature strength. The bottom heat conductivity makes the product have good heat insulation performance. Excellent electrical insulation performance. Non-toxic, harmless, no adverse effects on the environment, excellent tensile properties.

- Q: What is the diameter of the ceramic fiber? How to mix?

- Fiber diameter: rejection fiber more coarse, rejection fiber generally 3.0-5.0 - m, spinneret fiber is generally 2.0-3.0 - m;

- Q: Is aluminum silicate fiber poisonous?

- Then use the compressed air jet or use the wire throwing machine to turn the yarn into a fiber. After the cotton collector sets the cotton, it forms the ceramic fiber cotton. In the whole process of production, it can be found that the raw material does not contain toxic substances. Compared with asbestos, it is a substitute product of asbestos and contains no carcinogens.

- Q: What is the good heat insulation effect of glass fiber and aluminum silicate fiber, what are their respective advantages and disadvantages?

- Advantages and disadvantages of aluminum silicate fiber: high temperature insulation, heat preservation, fire resistance, noise reduction, insulation, light weight. Disadvantages: compressive resistance, bending force is relatively poor, easy to produce dust, waterproof performance is not very good.

- Q: The difference between the ceramic fiber blanket and rock cotton blanket

- The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.

- Q: Ceramic fiber material fire shutter door how many square?

- Now there are two kinds of rolling to use ceramic fiber: a called inorganic super fire shutter (commonly known as the double track curtain), the curtain surface is glass fiber cloth + ceramic fiber cloth + ceramic fiber blanket + aluminum foil cloth, one is WFJ (glass fiber cloth + ceramic fiber cloth + glass fiber cloth).

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Asia;America; Africa; Europe; and so on |

| Company Certifications | Quality management system certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 21-50 pepole |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | About 230,000 square meters |

| No. of Production Lines | 37 lines |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Ceramic Fiber Bulk 1260 HP - High Performance Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 KG kg

- Supply Capability:

- 1000 Tons Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords