Tx-5 Polypropylene Non-Woven Geotextile Roll with High-Performance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Type:

Geotextiles, Nonwoven Geotextile woven Geotextile

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

Model Number:

CMAX-S001

Geotextile Type:

Non-Woven Geotextiles Woven Geotextiles

Width:

1m-8m

Length:

Customer Requirment

Weight:

100g/m2-1500g/m2

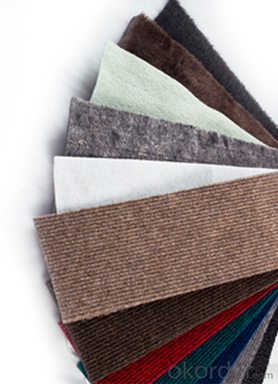

Color:

White, Black, etc

Application:

Water Conservancy

Material:

PP(polypropylene) PET (polyester)

Certificate:

CE/ISO9001

Break Elongation:

25%~100%

Tensile Strength:

from 2.5 KN/m to 25KN/m

Geotextiles

Divider

Protect the integrity of your gabion basket installation with high-quality geotextiles

between your gabion structures and the soil. We supply only the highest quality of both

woven and non-woven geotextiles for gabion installations and other applications.

These geotextile filter fabric materials prevent the migration of fine soils to the spaces

between rock particles. The migration of fine soil into your gabion structure can cause

subsidence problems below or behind the gabion structure in time if not applied correctly

and will stir up problems – especially in sandy soils. Clay soils do not generally

require a geotextile filter fabric as they seldom leach through the basket section. We

recommend using a suitable geotextile where the gabion is in contact with earth, this will

limit any movement of soils through a gabion structure. In soft soil foundations

especially and wherever overlaps or joins are required, we suggest a minimum overlap of

300mm(1 ft).

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in stormwater detention systems?

- Yes, geotextiles can be used in stormwater detention systems. Geotextiles are commonly used to separate different soil layers and provide filtration and drainage in stormwater management systems. They can help prevent soil erosion, improve water quality, and enhance the overall performance of stormwater detention systems.

- Q: How do geotextiles contribute to disaster management?

- Geotextiles contribute to disaster management by providing effective erosion control, stabilizing slopes, and preventing soil movement during natural disasters such as floods, landslides, and earthquakes. They also help in the construction of temporary shelters, emergency access roads, and retaining walls, enabling quick response and recovery efforts after a disaster. Additionally, geotextiles can be used for water filtration, drainage, and reinforcement, enhancing the overall resilience and effectiveness of disaster management strategies.

- Q: Can geotextiles be used for soil reinforcement in embankments?

- Yes, geotextiles can be used for soil reinforcement in embankments. Geotextiles are commonly used in civil engineering projects to improve the stability and strength of soil structures. They are effective in preventing soil erosion, enhancing drainage, and distributing loads, making them suitable for reinforcing embankments and preventing slope failures.

- Q: Geotextile how to construction?

- Geotextile construction is relatively simple with artificial roll: cloth to be flat, and appropriate to leave the deformation margin. The installation of filament or short wire geotextiles is usually carried out by means of lap, suture and welding. The width of the stitching and welding is generally 0.1 m or more, and the lap width is generally 0.2 m or more. May be exposed to long-term geotextile. It should be welded or stitched. All suture centers need to be carried out continuously (for example, spot joints are not allowed). Before the overlap, the geotextile must overlap at least 150mm. The minimum stitch is at least 25 mm from the weaving edge (the edge of the material exposed). Stitching the seam of the soil includes the first line and the line of the chain. The line used for suturing should be a resin material with a minimum tension of more than 60N. And with geotextile quite or beyond the anti-chemical corrosion and anti-ultraviolet ability. Any "missing needle" on the sewn geotextile must be re-sewn in the affected area. It is necessary to take appropriate measures to prevent the soil, particulate matter or foreign matter from entering the geotextile after installation.

- Q: Can geotextiles be used in stormwater management systems?

- Yes, geotextiles can be used in stormwater management systems. Geotextiles are often used as a filtration and separation layer in stormwater management systems to prevent soil erosion and control sediment. They can also be used as a lining material in stormwater ponds and retention basins to enhance their functionality and improve water quality.

- Q: What are the different geotextile tensile strength test methods?

- There are several different geotextile tensile strength test methods, including the grab test, strip test, wide-width strip test, and trapezoid tear test. Each method has its own advantages and is used to evaluate the tensile strength and performance of geotextiles in different applications.

- Q: Performance index of composite geotextile

- Item Unit Area Quality g / m000 Remark Film Thickness mm0.25-0.350.3-0.5 Fracture strength KN / m57.510.012.014.016.018.0 Longitudinal transverse elongation% 30-100CBR Breaking strength KN≥1.11.51.92. 22.52.83.0 Tearing strength KN≥0.150.250.320.40.480.560.62 Vertical and horizontal peel strength N / cm6 Vertical and horizontal permeability coefficient cm / sk * 10-11-10-13k = 1.0-9.9

- Q: How do geotextiles help with soil stabilization?

- Geotextiles help with soil stabilization by acting as a physical barrier that prevents soil erosion and the displacement of soil particles. They provide support to the soil, distribute load stresses, and improve the overall stability of the ground. Additionally, geotextiles promote water drainage and filtration while preventing the loss of fine soil particles, thereby enhancing soil quality and preventing erosion-induced damage.

- Q: Pvc tube outsourcing geotextile, how to count how much geotextile

- Calculate the circumference of the bottom of the pipe by the diameter of the pipe, and the length of the pipe is multiplied by the length of the pipe, which is the area of the geotextile. Huazhi geotechnical materials manufacturers to answer your questions

- Q: Are geotextiles resistant to puncture?

- Yes, geotextiles are generally resistant to puncture. They are designed to be durable and strong, offering protection against punctures caused by sharp objects or external forces.

Send your message to us

Tx-5 Polypropylene Non-Woven Geotextile Roll with High-Performance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords